Abstract

The mixing mechanism of solid particles in the air spouted bed was studied by employing an impulse response technique. The particles, german millet and barley, were spouted by air in columns of diameter of 8.4 cm and 12.6 cm.

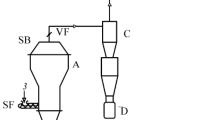

In the proposed theory, it was assumed that the mixing of the particles in the spouted bed occurs when they circulate through spout, fountain and annulus. Also a theoretical model was derived by assuming that the particle flow in the annulus is a combination of many annular plug flows while the flow in the spout as well as in the fountain is a mixed flow

The residence time distribution of the particles in the bed was measured by injecting a portion of colored particles into the feed line and analyzing the concentration of the colored particles in the discharge line. The experimental results and the proposed theory were most satisfactorily agreed when the null residence time in the spout and in the fountain was assumed in the theoretical model.

Similar content being viewed by others

References

Mathur, K.B., and Gishler, P.E.:AlChE J.,1, 157 (1955).

Romankov, P.G., and Rashkovskaya, N.B.: “Drying in a suspended state”, 2nd ed., in Russion Chem. Publ, House, Leningrad Branch (1968).

Abdelrazek, I.D.: ph. D. Thesis, Univ. of Tennessee (1969).

Nerneth, J., Palli, I., and Baticz, S.:Proc. Conf. Some Aspects phys. Chem., Budapest, 259 (1966).

Ratdiffe, J.S., and Rigby, GR.:Mech. Chem. Eng. Trans.,5, 1 (1969).

Uernaki, O., Fugikawa, M, and Kugo, M.:Kogyo Kagam Zassi,73, 453 (1970).

Uernaki, O., Fugikawa, M., and Kugo, M.:Kogyo Kagam Zassi,74, 933 (1971).

Kugo, M., Watanabe, N., Uemaki, O., and Shibata, T.: Bull. Hokkaido Univ., Sapporo, Jap.,39, 95 (1965).

Barton, R.K., Rigby, GR., and Ratcliffe, J.S.:Mech. Chem. Eng. Trans.,4, 105 (1968).

Quinlan, M.J., and Ratcliffe, J.S.:Mech. Chem. Eng. Trans.,6, 19 (1970).

Chatterjee, A.:Ind. Eng. Chem. Process Des. Develop.,9, 531 (1970).

Mann. U., and Crosby, E.J.:Ind. Eng. Chem. Process Des., Develop.,11, 314 (1972).

Mann. U., and Crosby, E.J.:Chem. Eng.Sci.,28, 623 (1973).

Velzen, D. Van, Flamm. H.J., Langenkamp, H. and Casile, A.:Can. J. Chem. Eng.,52, Apr., 156 (1974).

Mo, S.Y.: ph. D. Thesis, Korea Univ., Seoul Korea (1984).

Edwards, M.F. and Richardson, J.F.:Chem. Eng. Sci.,2, 1 (1957).

Smith, J.W. and Reddy, K.V.S.:The Can. J. Chem. Eng. Oct. 206 (1964).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kang, WK., Mo, SY. A study on mixing mechanism in air spouted beds. Korean J. Chem. Eng. 2, 87–92 (1985). https://doi.org/10.1007/BF02697555

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02697555