Abstract

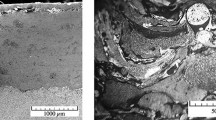

A comparative study of the retained austenite, grain size, hardness, and carbide precipitates was made on M-2 and M-4 high speed steels coated by chemical vapor deposition (CVD) and hardened by the salt bath method and vacuum gas quench method. Critical process parameters were identified. Hard coating of HSS and tool steel tooling with titanium carbide and titanium nitride by the CVD method is an accepted rapidly growing surface hardening process.

Similar content being viewed by others

References

P. Leckie-Ewing and W. A. Jacobsen:Metall. Trans. ASM, May 1970, vol. 1, pp. 14273/5.

ASM Handbook Committee:Atlas of Microstructure of Industrial Alloys, ASM, 1972, vol. 7, p. 118.

Robert Wilson:Metallurgy and Heat Treatment on Tool Steels, first edition, McGraw-Hill, 1975, chapters 2 and 3.

G. Krauss:Principles of Heat Treatment, first edition, ASM, 1980, chapter 7.

G. A. Roberts and R. A. Cary:Tool Steels, fourth edition, ASM, 1980, chapter 12.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Vagle, M. The role of a vacuum furnace in heat treating coated tool steels. J. Heat Treating 2, 121–129 (1981). https://doi.org/10.1007/BF02833228

Issue Date:

DOI: https://doi.org/10.1007/BF02833228