Abstract

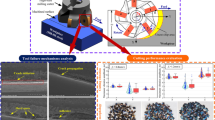

A research program was conducted to study tool wear on uncoated and coated (with TiN) high speed steel (HSS) for fluted end mill cutters. These cutters were used to machine AISI 4340 steel at axial and radial engagements of 12.7 mm (0.5 in.). All the machining was carried out using production conditions with the process periodically interrupted to carefully measure the wear condition of the cutting tool. Cutting conditions were carefully chosen so that a linear wear model for the useful life of the cutting tool could be statistically tested. One phase of testing used uncoated tools from 30 different suppliers and the nonstationary linear wear model provided a stochastic representation to determine tool quality using reliability and economic measures. Another phase used the coated tools and a stationary linear wear model to relate force, power, specific cutting energy, and mechanistic model parameters to service life measures. The cutters from each of these phases were carefully examined using optical and scanning electron microscopes so that the dominant wear mechanisms could be identified.

Similar content being viewed by others

References

M. Oyane, S. Shima, Y. Goto, and T. Nakayama:Int. J. Wear, 1984, 100, pp. 119–128.

E. Usui and T. Shirakashi:Int. J. Wear, 1984, 100, pp. 129–151.

E.M. Trent:Metal Cutting, 2nd edition, Bitterworths, London, Great Britain, 1984.

E.M. Trent: Conf. on Machinability (ISI, Inst. Metals, Inst. Mech. Eng. and Inst. Prod. Eng.), 1965, 77, 179, pp. 11.

E.G. Loewen and M.C. Shaw:Trans. ASME, 1954, Vol. 76, pp. 217–231.

G. Boothroyd:Proc. of Inst. Mech. Eng., 1963, Vol. 177, pp. 789–810.

H. Optiz and W. Konig:Proc. 8th International MTDR Conf., 1967, Manchester, England.

A.K. Sheikh and M. Ahmed: “Investigation Into the Bernestein’s Distribution with Engineering Applications,” Technical Report, the University of Petroleum and Minerals, Dahram, Saudia Arabia.

B.E. Klamecki:Proc. of the Symposium on Computer-Integrated Manufacturing and Robotics, 1984 Winter Annual Meeting American Society of Mechanical Engineers, pp. 303–309.

A.K. Sheikh: “Tool Life Variability and Its Significance in Automated Production,” Ph.D. Thesis, Michigan Technological University, 1978.

A.K. Sheikh, L.A. Kendall, and S.M. Pandit:J. of Engineering for Industry, 1980, Vol. 102, pp. 239–245.

S.B. Billatos: “Tool Changing Policies for a Multi-Tool Machining Center,” Ph.D. Thesis, Washington State University, 1985.

W.A. Kline: “The Prediction of Cutting Forces and Surfaces Accuracy for End Milling Processes,” Ph.D. Thesis, University of Illinois, Urbana-Champaign, 1982.

S. Soderberg and S. Hogmark:Wear, 1986, Vol. 110, p. 315.

V.A. Tipnis:Wear Control Handbook, Eds. M.B. Peterson and W.O. Winer, ASME, New York, NY 10017, p. 891.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bayoumi, A.E., Kendall, L.A. Modeling and measurement of wear of coated and uncoated high speed steel end mills. J. Materials Shaping Technology 6, 19–29 (1988). https://doi.org/10.1007/BF02833580

Issue Date:

DOI: https://doi.org/10.1007/BF02833580