Abstract

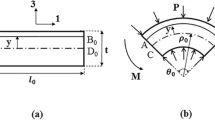

Based on a simple forcebalance method, an approximate analysis of the plane strain, deep drawing of sheet metal is carried out under the assumptions of Coulomb friction and the membrane theory of shells. Using this analysis with an estimate of the ratio of ultimate to yield load in plane strain enables us to predict the maximum work hardening of the part. This hardening is shown to depend upon the draw bead settings, the frictional conditions on the die and punch, the wall angle of the draw die, and certain uniaxial material properties, chiefly, the ratio of ultimate to yield stress, but also including the rate sensitivity and the anisotropy parameter. The limitations of this theory (mainly, the neglect of bending effects) are discussed. Comparison is made between predicted work hardening and measured yield strengths in a bumper facebar of dual phase steel. Springback of a gently curved part is calculated for preloads and postloads. It is shown that postloads are more effective, and that they can, in principle, reduce springback to low levels in any typical automotive sheet metal. In practice, it is difficult to transmit forces of sufficient magnitude to the region under the punch for certain materials.

Similar content being viewed by others

References

J. L. Duncan and J.E. Bird:Proceedings of the 10th Biennial Congress of the International Deep Drawing Research Group, Warwick, England, 1978, (also,Sheet Metal Ind., 1978, vol. 55, pp. 1015–25).

H. D. Nine:Mechanics of Sheet Metal Forming, D. P. Koistinen and N. -M. Wang, eds., Plenum Press, New York, NY, 1978, p. 179.

W. R. D. Wilson:Mechanics of Sheet Metal Forming, D. P. Koistinen and N. -M. Wang, eds., Plenum Press, New York, NY, 1978, p. 157.

W. R. D. Wilson:J. Applied Metalworking, 1979, vol. 1, pp. 7–19.

N. -M. Wang:J. Applied Metalworking, in press.

H. W. Swift:Engineering, 1948, vol. 166, pp. 333–35, 357–59.

H. L. Mantey and F. T. Burton:Soc. Automotive Engineers Congress, 1978, Paper No. 790281.

A. K. Ghosh and S. S. Hecker:Metall. Trans., 1975, vol. 6A, pp. 1065–1074.

E. Waddington, R. M. Hobbs, and J. L. Duncan:J. Applied Metalworking, 1980, vol. 1, pp. 35–47.

R. H. Wagoner:Metall. Trans., 1980, vol. 11A, pp. 165–75.

N. -M. Wang and M. L. Wenner:Mechanics of Sheet Metal Forming, D. P. Koistinen and N. -M. Wang, eds., Plenum Press, New York, NY, 1978, p. 367.

D. M. Woo and J. Marshall:The Engineer, 1959, vol. 208, pp. 135–36.

Y. Tsuyama, Y. Sakaya, K. Abe, and K. Yoshida: Reports I.P.C.R., 1965, vol. 41.

K. Yoshida: Sci. Papers I.P.C.R., 1965, vol. 59, pp. 87–96.

A. K. Ghosh:J. Eng. Mat. Tech., Transactions of the ASME, 1977, vol. 99, pp. 264–74.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wenner, M.L. On work hardening and springback in plane strain draw forming. J. Applied Metalworking 2, 277–287 (1983). https://doi.org/10.1007/BF02833912

Issue Date:

DOI: https://doi.org/10.1007/BF02833912