Abstract

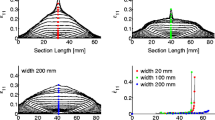

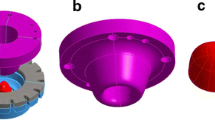

Finite element modeling (FEM) has been used to predict forming limit diagrams (FLDs) of thin sheets based on two-dimensional (2-D) finite thickness defects. The local growth of these defects is simulated until an arbitrary failure criterion is reached. Many aspects of this simulation re-produce the standard Marciniak-Kuczynski (M-K) results. For example, the plane strain intercept, FLD0, is sensitive to the material work hardening,n, and the strain rate sensitivity,m, but is not affected by the normal anisotropy,r. The positive side of the FLD was characterized by a line of logarithmic slopeP. The value ofP decreases sharply asn andm increase. The effect ofr depends on the choice of yield function. The absolute location of the FLD, as given by the FLD0, depends not only on the material properties, but also on the choice of failure criterion, defect geometry, and details of the simulative model (mesh size, number of defect dimensions,etc.). This is true of any measurement or simulation of the FLDs. Therefore, we propose that the FLD0 be used as the single “fitting parameter” between modeling and experimental results: a more realistic approach based on what is actually measured in the FLD experiments. This method allows clarification of the role of material plasticity properties(e.g.,n, m, andr) vs fracture properties (contained in the FLD0) in determining the shape of the FLDs.

Similar content being viewed by others

References

S.P. Keeler and W.A. Backofen:ASM Trans. Q., 1964, vol. 56, pp. 25–48.

S.P. Keeler: Society of Automotive Engineers Technical Paper No. 650535, 1965.

S.P. Keeler: Sc.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, 1961.

G.M. Godwin: Society of Automotive Engineers Technical Paper No. 680093, 1968.

S.S. Hecker:Sheet Metal Forming and Formability, Proc. 7th Biennial Cong, of International Deep Drawing Research Group, Hoogovens Ijmuiden Bv, Amsterdam, Holland, 1972, pp. 5.1–5.8.

M. Azrin and W.A. Backofen:Metall. Trans., 1970, vol. 1, pp. 2857–65.

Forming Limit Diagrams: Concepts, Methods, and Applications, R.H. Wagoner, K.S. Chan, and S.P. Keeler, eds., TMS, Warrendale, PA, 1989.

R. Hill:J. Mech. Phys. Solids, 1952, vol. 1, pp. 19–30.

Z. Marciniak and K. Kuczynski:Int. J. Mech. Sci., 1967, vol. 9, pp. 609–20.

Z. Marciniak, K. Kuczynski, and T. Pokora:Int. J. Mech. Sci., 1973, vol. 15, pp. 789–805.

K.S. Chan: inForming Limit Diagrams: Concepts, Methods, and Applications, R.H. Wagoner, K.S. Chan, and S.P. Keeler, eds., TMS, Warrendale, PA, 1989, pp. 73–110.

Mechanics of Sheet Metal Forming, D.P. Koistinen and N.M. Wang, eds., Plenum Press, New York, NY, 1978.

P.B. Mellor:Int. Met. Rev., 1981, vol. 26, pp. 1–20.

F.A. Nichols:Acta Metall., 1980, vol. 28, pp. 663–73.

P. Bate and D.B. Wilson:Int. J. Mech. Sci., 1984, vol. 26, pp. 363–72.

R.A. Ayres, W.G. Brazier, and V.F. Sajewski:J. Appl. Metalworking, 1979, pp. 41–49.

K. Chung and R.H. Wagoner:Int. J. Mech. Sci., 1987, vol. 29, pp. 45–59.

N.M. Wang: inNUMIFORM, J.F.T. Pittman, R.D. Wood, J.M. Alexander, and O.C. Zienkiewicz, eds., Pineridge Press, Swansea, U.K., 1982, pp. 797–806.

K. Chung and R.H. Wagoner:Metall. Trans. A., 1986, vol. 17A, pp. 1001–09.

K. Chung and R.H. Wagoner:Metall. Trans. A., 1988, vol. 19A, pp. 293–300.

Y. Germain, K. Chung, and R.H. Wagoner:Int. J. Mech. Sci., 1989, vol. 31, pp. 1–24.

J.R. Knibloe and R.H. Wagoner:Metall. Trans. A, 1989, vol. 20A, pp. 1509–21.

Y.H. Kim and R.H. Wagoner:Int. J. Mech. Sci., 1987, vol. 29, pp. 179–94.

Y.H. Kim and R.H. Wagoner:Scripta Metall., 1987, vol. 21, pp. 223–28.

Y.H. Kim and R.H. Wagoner: The Ohio State University, Columbus, OH, unpublished research, 1990.

R. Hill:Math. Proc. Camb. Phil. Soc, 1979, vol. 85, pp. 179–91.

W.F. Hosford:7th North American Metalworking Research Conf. Proc, Society of Manufacturing Engineers, Dearborn, MI, 1979, pp. 191–97.

R. von Mises:Gottinger Nachr. Math. Phys. Klasse, 1913, p. 582.

R. Hill:Proc. R. Soc. London, 1948, vol. 193A, pp. 281–97.

D. Zhou and R.H. Wagoner: The Ohio State University, Columbus, OH, unpublished research, 1989–1990.

R.W. Logan and W.F. Hosford:Int. J. Mech. Sci., 1980, vol. 22, pp. 419–30.

D.A. Burford and R.H. Wagoner: inForming Limit Diagrams: Concepts, Methods, and Applications, R.H. Wagoner, K.S. Chan, and S.P. Keeler, eds., TMS, Warrendale, PA, 1989, pp. 167–82.

R.W. Logan, DJ. Meuleman, and W.F. Hosford: inFormability and Metallurgical Structure, A.K. Sachdev and J.D. Embury, eds., TMS, Warrendale, PA, 1986, pp. 159–73.

J. Lian, D. Zhou, and B. Baudelet:Int. j. Mech. Sci., 1989, vol. 31, pp. 237–47.

J. Lian, F. Barlat, and B. Baudelet:Int. J. Plast., 1989, vol. 5, pp. 131–47.

A. Graf and W.F. Hosford:Metall. Trans. A, 1990, vol. 21A, pp. 87–94.

K.S. Chan, D.A. Koss, and A.K. Ghosh:Metall. Trans. A, 1984, vol. 15A, pp. 323–29.

D. Lee and F. Zaverl:Int. J. Mech. Sci., 1982, vol. 22, pp. 157–73.

R. Sowerby and J.L. Duncan:Int. J. Mech. Sci., 1971, vol. 13, pp. 217–29.

F. Barlat and O. Richmond:Mater. Sci. Eng., 1987, vol. 95, pp. 15–29.

F. Barlat:Mater. Sci. Eng., 1987, vol. 91, pp. 55–72.

A. Graf and W.F. Hosford: inForming Limit Diagrams: Concepts, Methods, and Applications, R.H. Wagoner, K.S. Chan, and S.P. Keeler, eds., TMS, Warrendale, PA, 1989, pp. 153–63.

D.V. Wilson and O. Ascelrad: inProc. 10th IDDRG Meeting, Warwick, U.K., Portcullis Press Ltd., Queensway House, Redhill, Surrey, U.K., 1978, pp. 155–66.

E. Schedin and A. Thuvander:International Deep Drawing Research Group Working Group Meeting, Schaffhausen, Switzerland, 1987.

D.N. Lee and Y.K. Kim: inForming Limit Diagrams: Concepts, Methods, and Applications, R.H. Wagoner, K.S. Chan, and S.P. Keeler, eds., TMS, Warrendale, PA, 1989, pp. 37–59.

P. Bate:Int. J. Mech. Sci., 1984, vol. 26, pp. 373–84.

S.S. Hecker:J. Eng. Mater. Technol. Trans. ASME, 1975, vol. 97H, pp. 66–73.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Narasimhan, K., Wagoner, R.H. Finite element modeling simulation of in-plane forming limit diagrams of sheets containing finite defects. Metall Trans A 22, 2655–2665 (1991). https://doi.org/10.1007/BF02851359

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02851359