Abstract

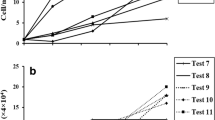

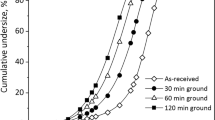

Batch tests were conducted to assess the potential use of ferrous sulfate and calcium polysulfide for the remediation of chromite ore processing residue (COPR). The remediation process entails addition of ferrous sulfate or calcium polysulfide to chemically reduce hexavalent chromium [Cr(VI)] to trivalent chromium [Cr(III)] in slurry form and pH adjustment to precipitate Cr(III) as chromium hydroxide. The present study investigates the effects of COPR particle size, treatment pH, and chemical dosage on the performance of the treatment. Smaller particle size resulted in increases in alkaline digestion and Toxicity Characteristic Leaching Procedure (TCLP) Cr(VI) concentrations for the untreated samples. The chemical reduction of Cr(VI) with ferrous iron and sulfides was non-stoichiometric. Four times the stoichiometric amount of ferrous iron of two times the stoichiometric amount of polysulfide were needed to meet both the New Jersey Department of Environmental Protection (NJDEP) regulatory limit of 240 mg/kg for Cr(VI) and EPA TCLP regulatory limit of 5 mg/L for chromium [C,r]. pH adjustment was necessary to prevent the formation of ettringite, a swell causing mineral, upon the introduction of sulfate to the COPR material via ferrous sulfate or calcium polysulfide. The slow hydration of some COPR minerals caused the pH of the treated COPR to creep upward during the curing period. However, when sufficient acid was added, the pH value was controlled at less than 9.27 for a curing period of 1.5 years, which prevented the formation of ettringite.

Similar content being viewed by others

References

Allied Signal, Process Description-Baltimore Works, 1982.

Buerge, I.J. and Hug, S.J., 1999, Influence of mineral murfaces on chromium(VI) reduction by iron(II). Environmental Science and Technology, 33, 4285–4291.

David, S.B. and Allisor, J.D., 1999, MINTEOA2, An equilibrium metal speciation model: User’s Manual 4.01; Environmental Research laboratory, US Environmental Protection Agency: Athens, GA.

Eary, L.E. and Rai, D., 1988, Chromate removal from aqueous wastes by reduction with ferrous iron. Environmental Science and Technology, 22, 972–977.

Geelhoed, J.S., Meeussen, J.C.N., Roe, M.J., Hiller, S., Thomas, R.P., Farmer, J.G. and Paterson, E., 2003, Chromium remediation or release? effect of iron(II) sulfate addition on chromium(VI) leaching from columns of chromite ore processing residue. Environmental Science and Technology, 37, 3206–3213.

Higgins, T.E., Halloran, A.R., Dobbins, M.E., and Pittignano, A.J., 1998, In-situ reduction of hexavalent chromium in alkaline soils enriched with chromite ore processing residue. Journal of Air, Waste Management Association, 48, 1100–1106.

Isenburg, J. and Moore, M., 1992, Generalized acid neutralization capacity test in T.M. Gilliam and C.C. Wiles (Eds.), Proceedings of the Second International Symposium on Stabilization and Solidification of Hazardous, Radioactive, and Mixed Wastes, ASTM STP 1123, American Society for Testing and Materials, Philadelphia, PA.

James, B.R., 1994, Hexavalent chromium solubility and reduction in alkaline soils enriched with chromite ore processing residue. Journal of Environmental Quality, 23, 227–233.

Kim, C., Zhou, Q., Deng, B., Thonton, E.C. and Xu, H., 2001, Chromium(VI) reduction by Hydrogen sulfide in aqueous media: stoichiometry and kinetics. Environmental Science and Technology, 35, 2219–2225.

Messer, A., Storch, P.Palmer, D., 2003, In-situ remediation of Cr(VI)—contaminated site using calcium polysulfide. Southwest Hydrology, 7.

Rietveld, H.M., 1969, A profile refinement method for nuclear and magnetic structures. Journal of Applied Crystallography, 2, 65–71.

Seaman, J., Bertsch, P. M. and Schwallie, L, 1999, In situ Cr(VI) reduction within coarse-textured, oxide-coated soil and aquifer systems using Fe(II) solutions. Environmental Science and Technology, 33, 938–944.

Snoeyink, V.L. and Jenkins, D., 1980, Water Chemistry. John Wiley & Sons, NY.

Su, C. and Ludwig R.D., 2005, Treatment of hexavalent chromium in chromite ore processing solid waste using a mixed reductant solution of ferrous sulfate and sodium dithionite. Environmental Science and Technology, 39, 6208–6216.

Van Geen A., Robertson A.P. and Leckie J.O., 1994, Complexation of carbonate species at the Goethite surface: implications for adsorption of metal ions in natural waters. Geochimica et Cosmochimica Acta, 58(9), 2073–2086.

Yahikozawa, K., Aratani, T., Ito, R., Sudo, T., and Yano, T., 1978, Kinetic studies on the lime sulfated solution (Calcium Polysulfide) process for removal of heavy metals from wastewater. Bulletin of the Chemical Society Japan, 51(2), 613–617.

Zachara, J.M., Girvin D.C., Schmidt R.L. and Resch C.T., 1987, Chromate adsorption on amorphous iron oxyhydroxide in the presence of major groundwater ions. Environmental Science and Technology, 21, 589–594.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wazne, M., Moon, D.H., Jagupilla, S.C. et al. Remediation of chromite ore processing residue using ferrous sulfate and calcium polysulfide. Geosci J 11, 105–110 (2007). https://doi.org/10.1007/BF02913922

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02913922