Abstract

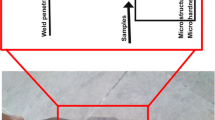

Three experimental flux cored wires(basic type) designed to produce systematic variations in the concentrations of boron of 32 ppm, 60 ppm and 103 ppm in the weld metal were prepared. A previous study of crack properties, morphology and microstructure in accordance with welding conditions was published in Welding Journal(Lee, 2006). Microstructure, strength and absorbed energy were studied for EH32 TMCP (Thermo-Mechanical Controlled Process) 40 mm thick plate welded with a gas-shielded flux cored arc welding.

The volume fraction of acicular ferrite decreased with increasing boron contents 32 to 103 ppm. The upper bainite instead of acicular ferrite was formed in the 103 ppm boron weld metal. The hardness values welded with 32 ppm and 60 ppm boron wire welds were in the range of Hv 190–210, while those welded with 103 ppm boron wire weld were in the range of Hv 230–235.

The absorbed energy slightly decreased with increasing boron contents from 32 ppm to 60 ppm, but significantly decreased with increasing boron contents from 60 ppm to 103 ppm. In the weld joint welded with 32 ppm and 60 ppm boron content electrode, no cracks were detected. However, cracks were detected the specimen welded with 103 ppm boron content electrode.

Similar content being viewed by others

References

Babu, S. S., Goodwin, G. M., Rohde, R. J. and Sielen, B. 1998. “Effect of Boron on the Microstructure of Low-carbon Steel Resistance Seam Welds,”Welding Journal, Vol. 77, No. 6, pp. 249–253.

Bonnet, C. and Charpentier, F. P., 1998, “Procedure of International Conference on Effect of Residual Impurity and Microalloying Elements on Weldability and Weld Properties,” London,The Welding Institute, Abington, U.K., 8.

Brown, A., Garnish, J. D. and Honeycombe, R. W. K., 1974, “The Distribution of Boron in Pure Iron,”Metal Science 8: 317–324.

Kohno, R., Takami, T., Mori, N. and Nagano, K. 1982, “New Flux of Improved Weld Metal Toughness of HSLA Steels,”Welding Journal, Vol. 61, No. 12, pp. 373–380.

Koukabi, A. H., North, T. H. and Bell, H. B. 1975, “Properties of Submerged arc Weld Deposits-effects of Zr,V and Ti/B,”Metal Const. and British W. J., 11: 639.

Lee, H. W. and Kang, S. W. 1999, “Microstructure and Impact Properties of 50 mm Single Pass Electrogas Weldments for EH36 TMCP Steels,”Journal of the Korea Welding Society, Vol. 17, No. 3, pp. 244–249.

Lee, H. W., 2006, “The Relationship Between Boron Content and Crack Properties in FCAW Deposited Metal,”Welding Journal, Vol. 85, No. 6 pp. 131–136.

Lee, H. W., Kang, S. W. and Um, D. S., 1998, “A Study on Transverse Weld Cracks in Thick Steel Plate with the FCAW Process,”Welding Journal, Vol. 77, No. 12, pp. 503–510.

Llewellyn, D. T. and Cook, W. T., 1974, “Metallurgy of Boron-treated Low-alloy Steels,”Metals Technology, 12: 517–529.

Maitrepierre, Ph., Thivellier, D. and Tricot, R., 1975, “Influence of Boron on the Decomposition of Austenite in Low Carbon Alloyed Steels,”Metallurgical Transactions, 6A: 287–321.

Melloy, G. F., Silmmon, P. R. and Podgursky, P. P., 1973, “Optimizing the Boron Effect,”Metallurgical Transactions, 4: 2279–2289.

Oh, D. W., Olson, D. L. and Frost, R. H., 1998, “The Influence of Boron and Titanium on Lowcarbon Steel Weld Metal,”Welding Journal, 68: 151–158.

Ohmori and Yamanaka, 1979, “Procedure of International Symposium on Boron Steel,” Milwaukee: 44–60.

Pargeter, R. J. and Dolby, R. E., 1985, “Guidelines for Classification of Ferritic Steel Weld Metal Microstructural Constituents Using the Light Microscope IIW Doc. IX-1377-85,”American Welding Society, Miami, Fla.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, H.W., Kim, Y.H., Lee, S.H. et al. Effect of boron contents on weldability in high strength steel. J Mech Sci Technol 21, 771–777 (2007). https://doi.org/10.1007/BF02916355

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02916355