Abstract

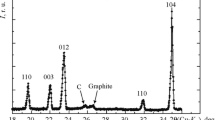

The Bureau of Mines investigated the formation of boron and boron-carbide coatings by vaporphase reactions. Optimum parameters were determined for hydrogen reduction of boron trichloride and for the formation of boron-carbide coatings on graphite by reaction with the deposited boron. At 1300°C, about 85 pct of the boron was deposited. Tungsten substrates did not react with the boron deposit; other substrates reacted to various extents. The hydrogen reduction of boron tribromide was briefly investigated. Boron carbide was deposited at 1300°C by adding methane to the boron trichloride-hydrogen feed gas. The chemical composition of the vapor-deposited boron carbide approximated B4C. A method of etching B4C was developed to study its microstructure. When boron was deposited on graphite at 1500°C, very hard, uniform, strongly adherent coatings of B4C were formed that might be useful in applications such as rocket nozzles and chemical reaction and processing vessels.

Similar content being viewed by others

References

C. F. Powell, I. E. Campbell, and B. W. Gonser:Vapor-Plating, John Wiley & Sons, New York, 1955.

A. G. Massey:Sci. Am., 1964, vol. 210, pp. 88–97.

J. W. Michel and C. A. Preskitt:Proc. Symp. Physics and Material Problems of Reactor Control Rods, Vienna, Nov. 11–15, 1963, pp. 409–38, Internat. Atomic Energy Agency, Vienna, Austria, 1964.

Cameron G. Harman:Non-Glassy Inorganic Fibers and Composites, NASA, SP-5055, August 1966, pp. 11–15.

J. C. Withers, L. C. McCandless, and B. A. Macklin:Proc. Conf. Chemical Vapor Deposition of Refractory Metals, Alloys, and Compounds, Gatlinburg, Tenn., Sept. 12–14, 1967, A. C. Schaffhauser, ed., pp. 315–27, Materials Science and Technol. Div., Am. Nuclear Soc. and Vapo-Metallurgy Comm. of SME of AIME, 1967.

American Petroleum Institute:Selected Values of Physical and Thermodynamic Properties of Hydrocarbons and Related Compounds, API Res. Project 44, Carnegie Inst. Technol., Pittsburgh, Pa., 1953.

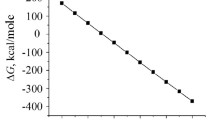

C. E. Wicks and F. E. Block: U.S. Bur. Mines Bull. 605, 1963.

M. K. Hansen and K. Anderko.Constitution of Binary Alloys, p. 256, McGraw-Hill Book Co., New York, 1958.

F. W. Hoertel: U.S. Bur. Mines Rept. Invest. 6731, 1966.

C. Hays, E. G. Kendall, and C. D. Hoskins:Metal Progr., 1965, vol. 87, pp. 106, 108.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Cochran, A.A., Stephenson, J.B. Boron and boron carbide coatings by vapor deposition. Metall Trans 1, 2875–2880 (1970). https://doi.org/10.1007/BF03037826

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF03037826