Abstract

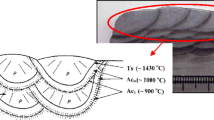

Active fluxes that are deposited on the TIG torch path before alloy melting can significantly increase weld penetrations. Several mechanisms (arc constriction, surface-tension-driven flow) for the active-TIG or A-TIG welding process have been postulated. The A-TIG welding of magnesium is discussed here using a simple model for the surface tension over the weld pool, real-time monitoring data, and measured characteristics from the fusion zone region. The chlorides selected for this investigation incorporated simple-metal elements from different group numbers (LiiaCl, CaiiaCl2, CdiibC12, PbivbCl2 and CeCl3) so that correlations between their chemistry and their effects during A-TIG welding could be established. Video recordings showed that chlorides intensified the visible light emission from the arc and affected its profile. Measurements during arc welding at a constant current demonstrated that all chlorides increased the arc voltage (thus the heat input) and the arc temperature. A-TIG weld cross sections revealed that chlorides increased fusion zone dimensions, as could be expected from greater heat inputs. While calculations suggested that surface tension might have altered weld pool circulation, specially designed experiments with low-energy-density laser beams were inconclusive. Among all tested chlorides, cadmium chloride was the most effective during A-TIG welding due to the high first ionization potential of cadmium, which correlated to several observations such as: low chloride melting, boiling, and dissociation temperatures, high welding voltage, augmented arc temperature, increased fusion zone penetration, and greater depth-to-width ratio.

Similar content being viewed by others

References

Gurevich, S.M., Zamkov, V.N., Kushmienko, N.A., 1965. Increase in the efficiency of penetration of titanium alloys in argon-arc welding, Avtomaticheskaya Svarka, 9: 1–4.

Gurevich, S.M., Zamkov, V.N, 1973. Metallurgical and technological features of titanium alloy welding when using fluxes, Titanium Science and Technology (Plenum Press, New York-London), 54(1): 551–557.

Howse, D., Lucas, W., 2000. Investigation into arc constriction by active fluxes for tungsten inert gas welding, Science and Technology of Welding and Joining, 5(3): 189–193.

Unknown authors, 2000. Activating flux — improving the performance of the TIG process, Welding and Metal Fabrication, 68 (2): 7–10.

Sire, S., Marya S.K., 2001. New Perspective in GTA Welding of Carbon Steels by the Use of Silica, International Journal of Forming Processes (Hermes Publications, France).

Paskell, T., Lundin, C, Castner, H., 1997. GTAW Flux Increases Weld Joint Penetration, Welding Journal, 76(4): 57–62.

Middel, W., Den Ouden. G., 1998. The Effect of Additives on Arc Characteristics in GTA Welding, Proceedings of 5th International Conference on Trends in Welding Research (Pine Mountain, GA, USA, 1–5 June 1998, ASM International), 304–300.

Modenesi, P.J., Apolinario, E.R, 1999. Study of A-TIG welding wit a single-component flux, Soldagem & Inspecao, 5(9): 9–16.

Tanaka, M., Shimizu, T., Terasaki, H., Ushio, M., Koshiishi, F., Yang, C.L., 2000. Effects of activating flux on arc phenomena in gas tungsten arc welding, Science and Technology of Welding and Joining, 5(6): 397–402.

Paton, B.E., Zamkov, V.N., Prilutsky, V.P., Poritsky, P.V., 2000. Contraction of the Welding Arc Caused by the Flux in Tungsten-Electrode Argon Arc Welding, Paton Welding Journal, 1: 5–11.

Simonik, A.G., 1974. Effect of Halides on the Penetration Effect in Argon and Welding Titanium Alloys, Svar Proiz, 3: 52–53.

Perry, N., Marya, S., Soutif, E., 1998. Study and Development of Flux enhanced GTA Penetrations in a Commercial Grade Titanium, Proceedings of 5 th International Conference on trends in Welding Research Proceedings of 5 th International Conference on trends in Welding Research (Pine Mountain, GA, USA, 1–5 June 1998, ASM International), 620–625.

Marya, M., Edwards, G.R., 2001. Flux-Assisted GTA Welding of Magnesium Alloys, Abstracts of Papers of the 82 nd Annual AWS Convention (Cleveland, Ohio, USA, May 6–10, American Welding Society), 161–162.

Marya, M., Edwards, G.R., 2001. The Contribution from Chlorides in the Gas Tungsten Arc Welding of Magnesium Alloys, accepted for publication in the Welding Journal (American Welding Society, Miami, FL, USA).

Haferkamp, H., Dilthey, U., Trager, G., Burmester, I., Niemeyer, M., 1998. Laser and Electron Beam Welding of Magnesium Alloys — Magnesium Alloys and Their Applications, Proceedings of Conference at Wolfsburg (28–30 April 1998), 595–600.

Marya, M., Olson, D.L., Edwards, G.R., 2000. Welding of Magnesium Alloys for Transportation Applications, Proceedings of the International Conference on Joining of Advanced Materials and Specialty Materials III (Edited by M. Sing, E. Indacochea, J. Dupont and T. Lienert, ASM Materials Solutions and Exposition, Americas Center, October 9–12, St Louis, Missouri, USA), 122–126.

Friedrich, H., Schuman, S., 2000. The Second Age of Magnesium — Research Strategies to Bring the Automotive Industry’s Vision to Reality, Proceedings of the Second Israeli International Conference on Magnesium Science and Technology (edited by E. Aghion and D. Eliezer, 22–24 Feb. 2000, Dead Sea, Israel), 9–18.

Keene, B.J., Mills, K.C., Bryant, J.W., Hondras, E.D., 1982. Effects of Interaction Between Surface Active Elements on the Surface Tension of Iron, Canadian Metallurgical Quarterly, 21(4): 393–409.

Heiple, C.R., Roper, J.R., 1982. Mechanism for Minor Element Effects on GTA Fusion Zone Geometry, Welding Journal, 61(4): 97s–102s.

Heiple, C.R., Roper, J.R., Stagner, R.T, Aden, R.J., 1983. Surface Active Elements Effects on the Shape of GTA, Laser and Electron Beam Welds, Welding Journal, 62(3): 72s–77s.

Mills, K.C., Keene, B.J., 1990. Factors Affecting Variable Penetration, International Materials Review, 35(4): 185–210.

Pollard, B., 1988. The Effects of Minor Elements on the Welding Characteristics of Stainless Steels, Welding Journal, 67(0): 202s–213s.

Walsh, D.W., Demmon, A., Gibbs, D., 1998. The Effects of Sulfide, Oxide and Halide Coatings on Bead Shape in Inconel 718 Weldments, Proceedings of 5 th International Conference on Trends in Welding Research (Pine Mountain, GA, USA, 1–5 June), 526–532.

Keene, B.J., Mills, K.C., Brooks. S.F., 1985. Surface Properties of Liquid Metals and Their Effects on Weldability, Materials Science and Technology, 1(7): 568–571.

Pierce, S.W., Burgardt, P., Olson, D.L., 1999. Thermocapillarity and Arc Plasma in Stainless Steel Welding, Welding Journal 78(2): 45s–52s.

Neff, D.V., 1988. Nonferrous molten metal processes, ASM Handbook Vol. 15 — Casting (ASM International, Materials Park, OH, USA), 445–496.

Hunter, G., Kenney, G.B., Ring, M., Russel, B.A., Eagar, T.W., 1978. Submerged Arc Welding of Titanium, Report AD-A085, Cambridge, MA.

Marya, S., Lemaitre, F., 1980. On the Elaboration of a New SAW Flux for Titanium, Journal of Less Common Metals, 69(1): 195–202.

Unknown author, 1972. Materials — Alloy Types and Fluxes, Welding Journal, 51 (8): 571–577.

Jarvis, B.L., Ahmed, N.U., 1998. The Behavior of Oxide Films during Gas Tungsten Arc Welding of Aluminum Alloys. Proceedings of 5 th International Conference on Trends in Welding Research (Pine Mountain, GA, USA, 1–5 June 1998), 410–414.

Chase, M.W., 1998. Journal of Physical and Chemical Reference Data, Monograph No. 9, NIST-JANAF Thermochemical Tables, Fourth Edition. Part I/II (Published by the American Institute of Physics for the National Institute of Standards and Technology).

Barim, I., 1993. Thermochemical Data for Pure Substances (VCH Verlagsgesellschaft mbH).

Jolly, W.L., 1970. The Synthesis and Characterization of Inorganic Compounds (Waveland Press Inc., Prospect Height, IL, USA).

Godard, H.P., 1967. The Corrosion of Light Metals (Wiley, NY, USA).

Jackson, C.E., 1970. The Science of Arc Welding, Internal document of the Union Carbide Corporation (No. 52–501). Also published in the Welding Journal, 39(4): 129s–146s, 39 (5): 177s-191s, 39 (6): 225s-230s.

Lancaster, J.F., 1984. The Physics of Welding (Pergamon Press, UK).

Sadek, A, Ushio, M., Matsuda, F., 1990. Effect of Rare Earth Metal Oxide Additions to Tungsten Electrodes, Metallurgical Transactions, 21A (12): 3221–3230.

Marya, M., Olson, D.L., 2001. Semi-Empirical Correlations and Electronic Model for Non-Metallic Inclusions as Thermoelectron Enhancers in Tungsten Cathodes, Proceedings of International Conference on Joining of Advanced and Specialty Materials (ASM International, Materials Solution Conference, Nov. 5–8, IN, USA).

CRC Handbook of Physics and Chemistry, 2001 (D.R. Lide, Editor in Chief, 82nd Edition, CRC Press, Boca Raton. FL, USA).

Chen, F.F., 1984. Introduction to Plasma Physics and Controlled Fusion, Second Edition (Plenum Press, NY).

Key, J.F., Chan. J.W., McIlwain, M.E., 1983. Process Variable Influence on Arc Temperature Distribution, Welding Journal, 62(7): 179s–184s.

Petrie, T.W., Pfender, E., 1970. The Influence of the Cathode Tip on Temperature and Velocity Fields in Gas-Tungsten Arc, Welding Journal, 49(12): 588s–600s.

Dunn, G.J., Allemand, CD., Eagar, T.W., 1980. Metal Vapor in Gas Tungsten Arcs- Part I. Spectroscopy and Monochromatic Photography, Metallurgical Transaction, 17A(10): 1851–1863.

Gutman, V., 1967. Halogen Chemistry (Academic Press, NV, USA).

Den Ouden, C., 1970. Physical Properties of the Arc Column, paper from the Colloquium on Physics of the Welding Arc (Lausanne, International Institute of Welding, American Council, American Welding Society, Miami, FL, USA).

Ito, Y., Koizumi, I., Yamauchi, N., Kohyama, A., 1975. Fundamental Studies of MIG Welding Underwater — MIG Welding in the Dry Environment of an Ambient Pressure, Welding Research Abroad, 21(1): 55–72.

Matsunawa, A., Nishiguchi, K., 1980. Arc Characteristics in high-pressure argon atmospheres, Proceedings International Conference on Arc Physics and Weld Pool Behavior (London, 8–12 May 1079, Publ. Abington, Cambridge), paper 9: 123–133.

Chase, T.F., Savage, W.F., 1971. Effect of Anode Composition on Tungsten Arc Characteristics, Welding Journal 50(11): 468s–473s.

Giu, A.C., Rokhlin, S.I., 1992. Technique for Simultaneous Real-Time Measurements of Weld Pool Surface Geometry and Arc Force, Welding Journal, 71(12): 473s–481s.

Converti, J., 1981. Plasma-jets in arc welding, Ph.D. Thesis (Mechanical Engineering, MIT, Cambridge, MA, USA).

Mendez, P.F., Eagar, T.W., 1998. Magnitude Scaling of Free Surface Depression during High Current Arc Welding. Proceedings of the 5 th International Conference on Trends in Welding Research (Pine Mountain, GA, USA. 1–5 June 1998), 13–18.

ASM Handbook — Vol. 3: Alloy Phase Diagrams, 1992 (ASM International, Materials Park, OH, USA).

Borland, J.C., 1970. Fundamentals of Solidification Cracking in Welds — Part I, Welding and Metal Fabrication, 47(1): 19–21; 23-26; 28–29.

Corrosion Handbook, Vol. 7, 1992 (ASM International, Materials Park, OH, USA).

Marya, M., Patay S., Marya, S.K., Edwards, G.R., 2001. Fundamentals Aspects in the Joining of Magnesium Alleys by the GTAW and LBW Processes, Proceedings of IWC 2001 (Feb. 15–17, 2001, New Delhi, India).

Hume-Rothery, W., 1966. Atomic Diameters and Solid Solubility Relations in Alloys, Acta Metallurgica, 14(1): 17–20.

Farson, D., Richardson, Li, 2001. Infrared Measurements of BM Temperature in Gas Tungsten Arc Welding, Welding Journal, 77(9): 396s–401s.

Selected Values of the Thermodynamic Properties of Binary Alloys, 1973 (prepared by P. Hultgren, P.D. Desai, D.T. Hawkin, N.I. Oleiser, K.K. Kelley, American Society for Metals, Metals Parks, OH, USA).

Iida, T., Guthrie, R.L., 1988. The Physical Properties of Liquid Metals (Clarendon Press, Oxford, UK).

ASM Handbook — Vol. 6: Welding, Brazing, and Soldering, 1993 (ASM International, Materials Park, OH, USA).

Glickstein, S., 1976. Temperature Measurements in a Free Burning Arc, Welding Journal, 55(8): 222s–299s.

Ushio, M., Fan, D., Tanaka, M., 1998. Contribution of Arc Plasma Radiation Energy to Electrodes, Transaction JWRI, 22 (2).

David, S.A., Vitek, J.M., 1989. Correlation between solidification parameters and microstructures, International Materials Review, 34(5): 213–245.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Marya, M. Theoretical and Experimental Assessment of Chloride Effects in the A-TIG Welding of Magnesium. Weld World 46, 7–21 (2002). https://doi.org/10.1007/BF03263386

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03263386