Abstract

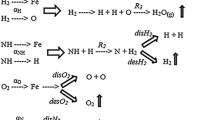

This study deals with nitrogen absorption and desorption during the autogenous welding of stainless steel, investigating the influence of the base metal nitrogen and surface-active element concentrations and nitrogen partial pressure in the shielding gas. The weld nitrogen concentration increases with shielding gas nitrogen content at low nitrogen partial pressures, but at higher partial pressures nitrogen absorption is balanced by N2 evolution. This steady-state nitrogen content is not influenced significantly by the base metal nitrogen content in low sulphur alloys, but in high sulphur alloys, an increase in the initial nitrogen concentration causes higher weld nitrogen contents over the entire range of partial pressures evaluated. The weld metal saturation limit is reached at progressively lower shielding gas nitrogen contents as the base metal nitrogen level increases. It is postulated that less nitrogen is required in the shielding gas to reach the saturation limit in the high sulphur alloys because an appreciable fraction of the nitrogen already present in the base metal is prevented from escaping by a higher level of surface coverage. A kinetic model can be used to describe this behaviour. The desorption rate constant decreases with an increase in sulphur content, but the absorption rate constant is not a strong function of the sulphur concentration. The higher rate of nitrogen removal at the onset of steady-state behaviour causes higher-nitrogen alloys to require more supersaturation prior to bubble formation.

Similar content being viewed by others

References

Lancaster, J.F. 1999. Metallurgy of welding. Cambridge, Abington Publishing.

Franks, R., Binder, W.O., and Thompson, J. 1955. Austenitic chromium-manganese-nickel steels containing nitrogen. Transactions of the American Society for Metals 47: 231 to 266.

Schaeffler, A.L. 1949. Constitution diagram for stainless steel weld metal. Metal Progress 56 (11): 680 to 680B.

Reed, R.P. March 1989. Nitrogen in austenitic stainless steels. JOM: 16 to 21.

Zackay, V.F., Carlson, J.F., and Jackson, P.L. 1956. High nitrogen austenitic Cr-Mn steels. Transactions of the ASM 8: 508 to 525.

Okagawa, R.K., Dixon, R.D., and Olson, D.L. 1983. The influence of nitrogen from welding on stainless steel weld metal microstructures. Welding Journal 62 (8): 204s to 209s.

Janik-Czachor, M., Lunarska, E., and Szklarska-Smialowska, Z. 1975. Effect of nitrogen content in a 18Cr-5Ni-10 Mn stainless steel on the pitting susceptibility in chloride solutions. Corrosion 31 (11): 394 to 398.

Ogawa, T., Aoki, S., Sakamoto, T., and Zaizen, T. 1982. The weldability of nitrogen-containing austenitic stainless steel: Part I — Chloride pitting corrosion resistance. Welding Journal 6 (5): 139 to 148.

Mozhi, T.A., Clark, W.A.T., Nishimoto, K., Johnson, W.B., and MacDonald, D.D. 1985. The effect of nitrogen on the sensitisation of AISI 304 stainless steel. Corrosion 41 (10): 555 to 559.

Beneke, R., and Sandenbergh, R.F. 1989. The influence of nitrogen and molybdenum on the sensitisation properties of low-carbon austenitic stainless steels. Corrosion Science 29 (5): 543 to 555.

Blake, P.D. April 1979. Nitrogen in steel weld metals. Metal Construction: 196 to 197.

Lakomskii, V.I., and Torkhov, G.F. 1969. Absorption of nitrogen from a plasma by liquid metal. Soviet Physics — Doklady 13 (11): 1159 to 1161.

Kuwana, T., and Kokawa, H. 1986. The nitrogen absorption of iron weld metal during gas tungsten arc welding. Transactions of the Japan Welding Society 17 (1): 20 to 26.

Blake, P.D., and Jordan, M.F. March 1971. Nitrogen absorption during the arc melting of iron. Journal of the Iron and Steel Institute: 197 to 200.

Den Ouden, G., and Griebling, O. 1989. Nitrogen absorption during arc welding. Proc. 2nd Int. Conf. Trends in Weld. Res. pp. 431–435. ASM International.

Katz, J.D, and King, T.B. 1989. The kinetics of nitrogen absorption and desorption from a plasma arc by molten iron. Metallurgical Transactions B 20B: 175 to 185.

Bandopadhyay, A., Banerjee, A., and DebRoy, T. 1992. Nitrogen activity determination in plasmas. Metallurgical Transactions B 23B: 207 to 214.

Gedeon, S.A., and Eagar, T.W. 1991. Thermochemical analysis of hydrogen absorption in welding. Welding Journal 69 (7): 264s to 271s.

Gedeon, S.A. 1987. Hydrogen assisted cracking of high strength steel welds. PhD dissertation, Boston, MIT.

Mundra, K., and DebRoy, T. 1995. A general model for partitioning of gases between a metal and its plasma environment. Metallurgical and Materials Transactions B 26B: 149 to 157.

Palmer, T.A., and DebRoy, T. 1996. Physical modeling of nitrogen partition between the weld metal and its plasma environment. Welding Journal 75 (7): 197s to 207s.

Pehlke, R.D., and Elliott, J.F. 1960. Solubility of nitrogen in liquid iron alloys. 1. Thermodynamics. Transactions of the Metallurgical Society of AIME 218: 1088 to 1101.

Wada, H., and Pehlke, R.D. 1977. Solubility of nitrogen in liquid Fe-Cr-Ni alloys containing manganese and molybdenum. Metallurgical Transactions B 8B: 675 to 682.

Kuwana, T., Kokawa, H., and Saotome, M. 1995. Quantitative prediction of nitrogen absorption by steel during gas tungsten arc welding. Proc. 3rd Int. Seminar Numerical Analysis of Weldability.

uutala, N. 1982. Effect of manganese and nitrogen on the solidification mode in austenitic stainless steel welds. Metallurgical Transactions A 13A: 2121 to 2130.

Arata, Y., Matsuda, F., and Saruwatari, S. 1974. Varestraint test for solidification crack susceptibility in weld metal of austenitic stainless steels. Transactions of the JWRI 3: 79 to 88.

Ogawa, T., Suzuki, K., and Zaizen, T. 1984. The weldability of nitrogen-containing austenitic stainless steel: Part II — Porosity, cracking and creep properties. Welding Journal 63 (7): 213s to 223s.

Uda, M., and Ohno, S. 1973. Effect of surface-active elements on nitrogen content of iron under arc melting. Transactions of the National Research Institute of Metallurgy 15 (1): 20 to 28.

Sinha, O.P., and Gupta, R.C. 1993. Fe-Cr melt nitrogenation when exposed to nitrogen plasma. ISIJ International 33 (5): 567 to 576.

Battle, T.D., and Pehlke, R.D. 1986. Kinetics of nitrogen absorption and desorption by liquid iron and iron alloys. Ironmaking & Steelmaking 13 (4): 176 to 189.

Elliott, J.F., and Gleiser, M. 1963. Thermochemistry for Steelmaking I. p. 75, Reading, Addison-Wesley.

Kubaschewski, O., Alcock, C.B., and Spencer, P.J. 1993. Materials Thermochemistry. Oxford Pergamon Press.

Weast, R.C. 1981. CRC Handbook of Chemistry and Physics. Boca Raton, Florida, CRC Press.

Belton, G.R. 1993. How fast can we go? The status of our knowledge of the rates of gas-liquid metal interactions. Metallurgical Transactions B 24B: 241–258.

Turkdogan, E.T. 1996. Fundamentals of Steelmaking. London, The Institute of Materials.

The 19th Committee on Steelmaking, The Japan Society for the Promotion of Science. 1988. Steelmaking data sourcebook. New York, Gordon and Breach.

Fruehan, R.J. Nitrogen control in chromium steels. INFACON 6. Proc. 1st Int. Chromium Steel and Alloy Congress, pp. 35–41. SAIMM.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Du Toit, M., Pistorius, P.C. Nitrogen Control During the Autogenous ARC Welding of Stainless Steel. Weld World 47, 30–43 (2003). https://doi.org/10.1007/BF03266398

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266398