Abstract

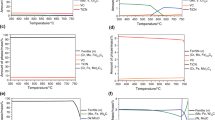

Four methods of preheat temperature prediction were compared for structural steels, from a mild steel and a TS780 grade steel with carbon contents between 0.034% and 0.234% C. The BS method and the CEN method predict almost the same preheat temperatures except for the carbon-reduced steels. The prediction by the AWS hydrogen-control method and the CE T method are conservative for mild steels and C-Mn steels. All the methods predict the same preheat temperatures for the TS780MPa steel with 0.11% C. However, only the CEN method can properly predict necessary preheat temperatures for the Cu-precipitated steel grade TS780MPa. Necessary preheat temperatures for very low carbon line-pipe steel grade API X80 is preferably predicted by the AWS hydrogen-control method and CEN method. Significant discrepancy in the prediction by these methods solely stems from a difference of carbon equivalency employed. All the preheat predictive methods are intended for avoiding HAZ cold cracking. It is necessary to consider the likelihood of weld metal cold cracking in determining the necessary preheating temperature when welding high strength steels with improved weldability.

Similar content being viewed by others

References

CEN/TC 121/SC 4/WG1 Report N111, “Guidelines for the avoidance of cold cracks — a comparison method —”, 1999.

H. Christoph, D. Steinbichler and H. Wegmann: IIW Doc. IX-1999–01.

N. Yurioka and S. Ohkita: Welding of structural steels, Sanpo-Publishing, Tokyo, (1998), p. 40 (in Japanese).

N. Yurioka, M. Okumura, T. Kasuya, and H. J. U. Cotton: Metal Construction, 19 (1987), 217R.

BS 5135 “Process of Arc Welding of Carbon and Carbon-Manganese Steel”, British Standards Institution (1984).

AWS D1.1 Annex XI “Guideline on alternative methods for determining preheat” (1996).

D. Uwer and H. Hohne: IIW Doc. IX-1631–91, “Determination of suitable minimum preheating temperatures for the cold-crack-free welding of steels”, (1991).

N. Yurioka, T. Kasuya: Welding in the World, 35 (1995), p. 327.

Y. Tomita et al.: ISIJ International, 34 (1994), p. 836.

N. Yurioka: ISIJ International, 41 (2001), p. 566.

N. Yurioka, H. Suzuki and S. Ohshita: Welding J., 62 (1983), p. 147s.

Canadian Standard CAN/CSA-Z184, Z-186–1986.

ASTM A 1005/A-00 Standard Specification for Steel Line Pipe.

ASME B16.49–2000 Factory-made wrought steel butt welding induction bend.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Yurioka, N. Comparison of Preheat Predictive Methods. Weld World 48, 21–27 (2004). https://doi.org/10.1007/BF03266410

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266410