Abstract

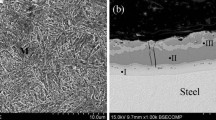

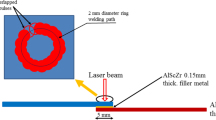

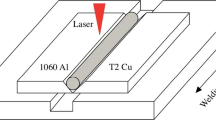

Laser beam welding of aluminium alloys becomes increasingly important. However, in welding of high-strength aluminium alloys one main problem is hot cracking in the weld metal. Increasing the silicon content in the weld metal by introducing filler wire can reduce the occurrence of hot cracking. Today available filler wires are limited to 12 % Si since materials having higher Si content cannot be processed into wire. Spray forming is capable of producing hypereutectic Al-Si wires with a fine-grained microstructure in comparison with conventional cast alloys. In this investigation, the performance of spray formed AlSi18 wire was compared to standard AlSi12 wire. In view of process behaviour, no significant effect of the increased silicon content was observed. Furthermore, it was proven that the hot cracking susceptibility was decreased with increasing silicon content.

Similar content being viewed by others

References

Hilbinger R. M., Utz H.: Heißrissbildung beim Schweißen von Aluminium in Blechrandlage, Wissenschaft Verlag, München, 2000.

Mousavi M.G., Cross C.E., Grong Ø.: Effect of scandium and titanium-boron on grain refinement and hot cracking of aluminum alloy 7108, Science and Technology of Welding and Joining, 1999, Volume 4, No. 6.

Spittel M., Spittel T.: Influence of alloying elements and impurities on the hot and cold forming properties of aluminium alloys, Aluminium 75, 1999, 10, pp. 888–892.

Schumacher J.: Erfahrungen beim Laser-strahlschweißen von Aluminium für die Luftfahrt, in Laserstrahlfügen: Prozesse, Systeme, Anwendungen, Trends, Strahltechnik Band 19, Bremen, 2002.

Hummert K., Frech W., Schwagereit M.: Industriell hergestellte sprühkompaktierte Aluminiumlegierungen, Metall, 1999, 53, 9, pp. 496–500.

Schimanski K., Schulz A., Vetters H., Mayr P.: Sprühkompaktieren aushärtbarer Al-Cu-Legierungen, In Sprühkompaktieren — Spray forming, Kolloquium, 2001, 5, Universität Bremen, pp. 193–210.

Lawley A.: Melt atomization & spray deposition, Quo Vadis, in: K. Bauckhage, V. Uhlenwinkel, U. Fritsching (Eds.), Spray Deposition and Melt Atomization SDMA 2000, University Bremen, Germany, 2000, pp. 3–15.

Palm F.: Laserstrahlschweißen an Al-Werkstoffen der Luft- und Raumfahrt, In DVS-Berichte — Schweißen und Schneiden, 2000, DVS-Verlag, pp. 199–206.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Vollertsen, F., Buschenhenke, F. & Seefeld, T. Reduction of Hot Cracking in Laser Welding using Hypereutectic AlSi Filler Wire. Weld World 52, 3–8 (2008). https://doi.org/10.1007/BF03266635

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266635