Abstract

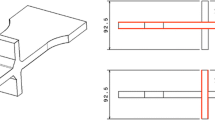

In this study fatigue testing and defect assessment were carried out on specimens welded with robotic and manual welding using flux cored (FCAW) and metal cored (MCAW) filler materials in order to study the effect of the welding method on the fatigue strength and weld quality. Thirteen different batches were investigated of which two was shot peened before fatigue testing. The local weld geometry was measured for all the specimens before testing. The specimens welded with flux cored weld wire showed the best fatigue strength, small defects and low residual stresses. Large scatter in the fatigue data is observed, especially when manual welding is employed. The few largest defects were removed by the shot peening process, although small defects survived. This led to a smaller scatter in fatigue live for the shot peened specimens. Linear elastic fracture mechanics, LEFM, was employed for analysis of the fatigue test results. The fatigue life predictions using a 2D LEFM FE-model for simulating a continuous cold lap defect along the weld toe showed a qualitative agreement with the fatigue test results. The 2D analysis showed that a continuous cold lap defect should be no more than 0.5 mm deep in order to comply with the requirement of fatigue lives for normal weld quality according to the IIW design rules. For larger defects (> 0.8 mm) an increased toe radius will have a small effect on the fatigue strength. A 3D LEFM analysis of crack growth from a spatter-induced cold lap defect was also carried out. This showed similar trends in crack growth compared to the 2D analysis of a continuous cold lap, although the spatter-induced cold lap defect (semi-elliptical) had a longer fatigue life (x2.7), and hence is less dangerous from a fatigue point of view.

Similar content being viewed by others

References

Barsoum Z.: Fatigue and quality analysis of cruciform joints welded with different methods, IIW doc. IIW-XIII-2136–06, 2006.

Barsoum Z., Samuelsson J.: Fatigue assessment of cruciform joints welded with different methods, Steel Research International, 2006, 77, No. 12, pp. 882–888.

Martinson J.: Fatigue assessment of complex welded structures, Doctoral Thesis, Dept. of Aeronautical and Vehicle Engineering, KTH, Sweden, 2005, ISBN 91-2783-968–6.

Samuelsson J.: Cold laps and weld quality acceptance limits, Design and Analysis of Welded High Strength Steel Structures, 2002, pp. 151–163, Stockholm, EMAS.

Samuelsson J.: Fatigue design of vehicle components methodology and applications, Dept. of Aeronautical Structures and Materials, Report no. 88–23, Doctoral Thesis, The Royal Institute of Technology, Stockholm, 1988.

Barsoum Z.: Weld quality assessment of test specimens, report 2003–9, Master thesis, Department of Aeronautical and Vehicle Engineering, Royal Institute of Technology, 2003, Stockholm.

Barsoum Z.: Residual stress analysis and fatigue of welded structures, Licentiate Thesis, Dept. of Aeronautical and Vehicle Engineering, KTH, Sweden, 2006, ISBN 91-7178-264–8.

Hobbacher A.: Recommendations for fatigue design of welded joints and components, IIW doc. XIII-2151r1-07/XV-1254r1–07.

Lopez Martinez L., Korsgren P.: Characterization of initial defect distribution and weld geometry in welded fatigue test specimens, Fatigue under Spectrum Loading and Corrosive Environment, 1993, pp. 3–21, Warley, UK, EMAS.

Signes E.G. et al: Factors affecting the fatigue strength of welded high strenght steels, Brit. Welding Journal, 1967, 14, 3, pp. 108–116.

Lundin M., Lopez Martinez L., Hedegárd J., Weman K., High productive welding — fatigue properties of weld-ments, Welded High Strength Steel Structures, pp. 33–47, Stockholm Oktober 1997, Blom A.F., EMAS.

Lopez Martinez L.: Fatigue behaviour of welded high-strength steels, report 1997–30, Doctoral dissertation, Department of Aeronautical and Vehicle Engineering, Royal Institute of Technology, 1997, Stockholm.

FRANC2D, Version 3.2 http://www.cfg.cornell.edu/

AFGROW, Version 4.0005. http://fibec.flight.wpafb.af.mil/fibec/afgrow.html

Nykänen T., Marquis G., Bjôrk T.: Fatigue analysis of non-load-carrying fillet welded cruciform joints, Engineering Fracture Mechanics, 2007, vol 74, pp. 399–415.

Forman R.G., Mettu S.R.: Behavior of surface and corner cracks subjected to tensile and bending loads in Ti-6Al-4V alloy, Fracture Mechanics 22nd Symposium, Vol. 1, ASTM STP 1131, H.A. Ernst, A. Saxena and D.L. McDowell, eds., American Society for Testing and Materials, Philadelphia, 1992.

FRANC3D, Version 3.1 http://www.cfg.cornell.edu/

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Barsoum, Z., Jonsson, B. Fatigue Assessment and Lefm Analysis of Cruciform Joints Fabricated with Different Welding Processes. Weld World 52, 93–105 (2008). https://doi.org/10.1007/BF03266657

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266657