Abstract

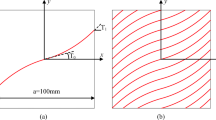

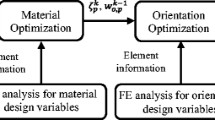

In this work, a surrogate assisted optimization method is utilized to optimize buckling loads of variable stiffness composites made by fiber steering. To improve the efficiency of optimization procedure, an expected improvement criterion is employed. Moreover, considering uncertainties of the fiber placement, a robust surrogate, least square support vector regression (LSSVR) considering empirical and structural risks is integrated with the expected improvement (EI) criterion and applied to two applications. The first case is the fiber path design of a variable stiffness plate under the compression load. The second one is the fiber path design of a variable stiffness cylinder under the bending load. According to results of the optimization, the buckling load of the variable stiffness plate has 52.63% improvement than the constant stiffness plate and 24.3% improvement than the quasi-isotropic plate. The buckling load of the variable stiffness cylinder has 40.22% improvement than the constant stiffness cylinder and 31.25% improvement than the quasi-isotropic cylinder. Furthermore, to verify the robustness of optimal design variables for the variable stiffness cylinder, the perturbed optimum design is presented and demonstrates that the results are reliable.

Similar content being viewed by others

Notes

N denotes the number of the sample points

References

Abdalla MM, Gürdal Z, Abdelal GF (2008) Thermomechanical response of variable stiffness composite panels. J Therm Stresses 32(1–2):187–208

An W, Sun Y (2006) An equivalence between SILF-SVR and ordinary kriging. Neural Process Lett 23(2):133–141

András P (2002) The equivalence of support vector machine and regularization neural networks. Neural Process Lett 15(2):97–104

Backlund PB, Shahan DW, Seepersad CC (2012) A comparative study of the scalability of alternative metamodelling techniques. Eng Optim 44(7):767–786

Bisagni C, Lanzi L (2002) Post-buckling optimisation of composite stiffened panels using neural networks. Compos Struct 58(2):237–247

Blom AW, Setoodch S, Hol JMAM, Gürdal Z (2008) Design of variable-stiffness conical shells for maximum fundamental eigenfrequency. Comput Struct 86(9):870–878

Blom AW, Stickler PB, Gürdal Z (2010) Optimization of a composite cylinder under bending by tailoring stiffness properties in circumferential direction. Compos Part B Eng 41(2):157–165

Clarke SM, Griebsch JH, Simpson TW (2005) Analysis of support vector regression for approximation of complex engineering analyses. J Mech Des 127(6):1077–1087

Forrester AIJ, Keane AJ (2009) Recent advances in surrogate-based optimization. Prog Aerosp Sci 45(1):50–79

Forrester AIJ, Sóbester A, Keane AJ (2007) Multi-fidelity optimization via surrogate modelling. Proc R Soc A Math Phys Eng Sci 463(2088):3251–3269

Gürdal Z, Olmedo R (1993) In-plane response of laminates with spatially varying fiber orientations: variable stiffness concept. AIAA J 31(4):751–758

Gürdal Z, Tatting BF, Wu CK (2008) Variable stiffness composite panels: effects of stiffness variation on the in-plane and buckling response. Compos A: Appl Sci Manuf 39(5):911–922

Hyer MW, Charette RF (1991) Use of curvilinear fiber format in composite structure design. AIAA J 29(6):1011–1015

Hyer MW, Lee HH (1991) The use of curvilinear fiber format to improve buckling resistance of composite plates with central circular holes. Compos Struct 18(3):239–261

Ijsselmuiden ST, Abdalla MM, Gürdal Z (2010) Optimization of variable-stiffness panels for maximum buckling load using lamination parameters. AIAA J 48(1):134–143

Jin R, Chen W, Simpson TW (2001) Comparative studies of metamodeling techniques under multiple modeling criteria. Struct Multidiscip Optim 23(1):1–13

Jones DR, Schonlau M, Welch WJ (1998) Efficient global optimization of expensive black-box functions. J Glob Optim 13(4):455–492

Khani A, Ijsselmuiden ST, Abdalla MM, Gürdal Z (2011) Design of variable stiffness panels for maximum strength using lamination parameters. Compos Part B Eng 42(3):546–552

Khani A, Abdalla MM, Gürdal Z (2012) Circumferential stiffness tailoring of general cross section cylinders for maximum buckling load with strength constraints. Compos Struct 94(9):2851–2860

Kim BC, Potter K, Weaver PM (2012) Continuous tow shearing for manufacturing variable angle tow composites. Compos A Appl Sci Manuf 43(8):1347–1356

Kim BC, Weaver PM, Potter K (2015) Computer aided modeling of variable angle tow composites manufactured by continuous tow shearing. Compos Struct 129:256–267

Kitayama S, Arakawa M, Yamazaki K (2011) Sequential approximate optimization using radial basis function network for engineering optimization. Optim Eng 12(4):535–557

Kůrková V, Kainen PC (2014) Comparing fixed and variable-width gaussian networks. Neural Netw 57:23–28

Lee Y, Oh S, Choi DH (2008) Design optimization using support vector regression. J Mech Sci Technol 22(2):213–220

Lopes CS, Camanho PP, Gürdal Z, Tattting BF (2007) Progressive failure analysis of two-placed variable-stiffness composite panels. Int J Solids Struct 44:8493–8516

Nakayama H, Arakawa M, Sasaki R (2002) Simulation-based optimization using computational intelligence. Optim Eng 3(2):201–214

Nik MA, Fayazbakhsh K, Pasini D, Lessard L (2012) Surrogated-based multi-objective optimization of a composite laminate with curvilinear fiber. Compos Struct 94(8):2306–2313

Nik MA, Fayazbakhsh K, Pasini D, Lessard L (2014a) A comparative study of metamodeling methods for the design optimization of variable stiffness composites. Compos Struct 107:494–501

Nik MA, Fayazbakhsh K, Pasini D, Lessard L (2014b) Optimization of variable stiffness composites with embedded defects induced by automated fiber placement. Compos Struct 107:160–166

Raju G, Wu ZM, Kim BC, Weaver PM (2012) Prebuckling and buckling analysis of variable angle tow plates with general boundary conditions. Compos Struct 94(9):2961–2970

Rikards R, Abramovich H, Kalnins K, Auzins J (2006) Surrogate modeling in design optimization of stiffened composite shells. Compos Struct 73(2):244–251

Rouhi M, Ghayoor H, Hoa SV, Hojjati M (2014) Effect of structural parameters on design of variable-stiffness cylinders made by fiber steering. Compos Struct 118:472–481

Rouhi M, Ghayoor H, Hoa SV, Hojjati M (2015a) Multi-objective design optimization of variable stiffness composite cylinder. Compos Part B Eng 69:249–255

Rouhi M, Ghayoor H, Hoa SV, Hojjati M (2015b) The effect of the percentage of steered piles on the bending-induced buckling performance of a variable stiffness composite cylinder. Sci Eng Compos Mater 22(2):149–156

Sanchez E, Pintos S, Queipo NV (2008) Toward an optimal ensemble of kernel-based approximations with engineering applications. Struct Multidiscip Optim 36(3):247–261

Setoodeh S, Abdalla MM, Gürdal Z (2006) Design of variable-stiffness laminates using lamination parameters. Compos Part B Eng 37(4):301–309

Setoodeh S, Abdalla MM, Ijsselmuiden ST, Gürdal Z (2009) Design of variable-stiffness composite panels for maximum buckling load. Compos Struct 87(1):109–117

Simpson TW, Peplinski JD, Koch PN, Allen JK (2001) Metamodels for computer based engineering design: survey and recommendations. Eng Comput 17(2):129–150

Trafalis TB, Gilbert RC (2006) Robust classification and regression using support vector machines. Eur J Oper Res 173(3):893–909

Viana FAC (2011) SURROGATES Toolbox User’s Guide. Gainesville, FL, USA, version 3.0 edn

Viana FAC, Haftka RT. Importing uncertainty estimates from one surrogate to another. 50th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference 17th AIAA/ASME/AHS Adaptive Structures Conference 11th AIAA No. 2009: 2237

Viana FAC, Haftka RT, Watson LT (2013) Efficient global optimization algorithm assisted by multiple surrogate techniques. J Glob Optim 56(2):669–689

Wang GG, Shan S (2007) Review of metamodeling techniques in support of engineering design optimization. J Mech Des 129(4):370–380

Wang H, Li EY, Li GY (2009) The least square support vector regression coupled with parallel sampling scheme metamodelling technique and application in sheet forming optimization. Mater Des 30(5):1468–1479

Wang H, Shan SQ, Wang GG, Li GY (2011) Integrating least square support vector regression and mode pursuing sampling optimization for crashworthiness design. J Mech Des 133(4)

Wang H, Ye F, Li EY, Li GY (2016) A comparative study of expected improvement-assisted global optimization with different surrogates. Eng Optim 48(8):1432–1458

Wang H, Ye F, Chen L, Li EY (2017) sheet metal forming optimization by using surrogate modeling techniques. Chin J Mech Eng 30(1)

Wu ZM, Weaver PM, Raju G, Kim BC (2012) Buckling analysis and optimisation of variable angle tow composite plates. Thin-Walled Struct 60(10):163–172

Wu ZM, Raju G, Weaver PM (2015) Framework for the buckling optimization of variable-angle tow composite plates. AIAA J 103(9):1–17

Wu ZP, Wang DH, Okolo NP, Jiang ZY, Zhang WH (2016) Unified estimate of gaussian kernel width for surrogate models. Neurocomputing 203:41–51

Acknowledgements

This work has been supported by Project of the Program of National Natural Science Foundation of China under the Grant Numbers 11172097, 11302266 and 61232014.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

There are three criteria of the surrogate as shown in the literature (Jin et al. 2001).

-

a)

R square

$$ {R}^2=1-\frac{{\displaystyle \sum_{i=1}^n{\left({y}_i-{\tilde{y}}_i\right)}^2}}{{\displaystyle \sum_{i=1}^n{\left({y}_i-\overline{y}\right)}^2}} $$(15) -

b)

relative average absoluteerror (RAAE)

$$ RAAE=\frac{{\displaystyle \sum_{i=1}^n\left|{y}_i-{\tilde{y}}_i\right|}}{n* STD} $$(16) -

c)

relative maximum absolute error (RMAE)

$$ RAAE=\frac{ \max \left(\left|{y}_1-{\tilde{y}}_1\right|,\left|{y}_2-{\tilde{y}}_2\right|,\dots, \left|{y}_n-{\tilde{y}}_n\right|\right)}{STD} $$(17)In this study, R 2 is not considered as the criterion of the surrogate due to small size of samples in practical engineering problems. RAAE indicates the overall accuracy of a surrogate over the entire design space. A high RMAE value indicates a large error in a region of the design space.

Rights and permissions

About this article

Cite this article

Ye, F., Wang, H. & Li, G. Variable stiffness composite material design by using support vector regression assisted efficient global optimization method. Struct Multidisc Optim 56, 203–219 (2017). https://doi.org/10.1007/s00158-017-1658-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-017-1658-8