Abstract

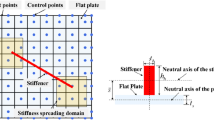

Stiffened plates are widely used in aerospace structures as load-bearing components. In order to obtain a novel design of stiffened structures with excellent performance, a generative design method of stiffened plates (GDMSP) based on the homogenization method is proposed in this paper, which optimizes the stiffener layout based on an equivalent model. Then, the detailed model can then be obtained by extracting the stiffener path from the discrete distribution of stiffener angles. Moreover, the optimized design can be obtained by size optimization based on the detailed model. Two examples are used to illustrate the proposed framework, including the stiffness maximization of a rectangle stiffener plate and the buckling load maximization of a square stiffener plate. The optimized stiffener configurations are characterized by streamlines and uniform lines, respectively. For the first example, the stiffness of the stiffener design has an improvement of 17%. For the second example, the optimized design improves the buckling load by 35%. Results indicate that the proposed method can effectively provide a novel generative design for stiffened plates. Moreover, the obtained results have a clear stiffener path and have a noticeable improvement in performance, which can be directly used to establish a detailed model.

Similar content being viewed by others

References

Aage N, Andreassen E, Lazarov BS, Sigmund O (2017) Giga-voxel computational morphogenesis for structural design. Nature 550:84

Ansola R, Canales J, Tárrago JA, Rasmussen J (2002) An integrated approach for shape and topology optimization of shell structures. Comput Struct 80:449–458. https://doi.org/10.1016/S0045-7949(02)00019-6

Bojczuk D, Szteleblak W (2008) Optimization of layout and shape of stiffeners in 2D structures. Comput Struct 86:1436–1446

Bruyneel M (2011) SFP–a new parameterization based on shape functions for optimal material selection: application to conventional composite plies. Struct Multidisc Optim 43:17–27

Bushnell D (1993) Optimization of composite, stiffened, imperfect panels under combined loads for service in the postbuckling regime. Comput Methods Appl Mech Eng 103:43–114. https://doi.org/10.1016/0045-7825(93)90041-U

Cai Y, Xu L, Cheng G (2014) Novel numerical implementation of asymptotic homogenization method for periodic plate structures. Int J Solids Struct 51:284–292

Cheng K-T, Olhoff N (1981) An investigation concerning optimal design of solid elastic plates. Int J Solids Struct 17:305–323

Cheng G, Cai Y, Xu L (2013) Novel implementation of homogenization method to predict effective properties of periodic materials. Acta Mech Sin 29:550–556

Chung J, Lee K (1997) Optimal design of rib structures using the topology optimization technique. Proc Inst Mech Eng -- Part C 211:425–437

Ding X, Yamazaki K (2004) Stiffener layout design for plate structures by growing and branching tree model (application to vibration-proof design). Struct Multidisc Optim 26:99–110

Gao T, Zhang W, Pierre D (2012) A bi-value coding parameterization scheme for the discrete optimal orientation design of the composite laminate. Int J Numer Methods Eng 91(1):98–114

Gersborg AR, Andreasen CS (2011) An explicit parameterization for casting constraints in gradient driven topology optimization. Struct Multidisc Optim 44:875–881

Hao P, Wang B, Li G (2012) Surrogate-based optimum design for stiffened shells with adaptive sampling. AIAA J 50:2389–2407

Hao P, Wang B, Tian K, Li G, Du K, Niu F (2016) Efficient optimization of cylindrical stiffened shells with reinforced cutouts by curvilinear stiffeners. AIAA J 54:1–14

Hao P, Liu DC, Zhang KP, Yuan Y, Wang B, Li G, Zhang X (2021) Intelligent layout design of curvilinearly stiffened panels via deep learning-based method. Mater Des 197:109180

Hirschler T, Bouclier R, Duval A, Elguedj T, Morlier J (2019) The embedded isogeometric Kirchhoff-Love shell: from design to shape optimization of non-conforming stiffened multipatch structures. Comput Methods Appl Mech Eng 349:774–797

Hu T, Ding X, Shen L, Zhang H (2020) Improved adaptive growth method of stiffeners for three-dimensional box structures with respect to natural frequencies. Comput Struct 239:106330. https://doi.org/10.1016/j.compstruc.2020.106330

Jármai K, Snyman JA, Farkas J (2006) Minimum cost design of a welded orthogonally stiffened cylindrical shell. Comput Struct 84:787–797

Ji J, Ding X, Xiong M (2014) Optimal stiffener layout of plate/shell structures by bionic growth method. Comput Struct 135:88–99. https://doi.org/10.1016/j.compstruc.2014.01.022

Kegl M, Brank B (2006) Shape optimization of truss-stiffened shell structures with variable thickness. Comput Methods Appl Mech Eng 195:2611–2634. https://doi.org/10.1016/j.cma.2005.05.020

Lam YC, Santhikumar S (2003) Automated rib location and optimization for plate structures. Struct Multidisc Optim 25:35–45. https://doi.org/10.1007/s00158-002-0270-7

Lazarov BS, Wang F (2017) Maximum length scale in density based topology optimization. Comput Methods Appl Mech Eng 318:826–844

Liu Y, Shimoda M (2015) Non-parametric shape optimization method for natural vibration design of stiffened shells. Comput Struct 146:20–31

Liu S, Li Q, Chen W, Hu R, Tong L (2015) H-DGTP—a Heaviside-function based directional growth topology parameterization for design optimization of stiffener layout and height of thin-walled structures. Struct Multidisc Optim 52:903–913

Liu H, Li B, Yang Z, Hong J (2017) Topology optimization of stiffened plate/shell structures based on adaptive morphogenesis algorithm. J Manuf Syst 43:375–384. https://doi.org/10.1016/j.jmsy.2017.02.002

Liu D, Hao P, Zhang K, Tian K, Wang B, Li G, Xu W (2020) On the integrated design of curvilinearly grid-stiffened panel with non-uniform distribution and variable stiffener profile. Mater Des 190:108556

Lund E (2009) Buckling topology optimization of laminated multi-material composite shell structures. Steel Constr 91:158–167

Lund E, Stegmann J (2010) On structural optimization of composite shell structures using a discrete constitutive parametrization. Wind Energy 8:109–124

Oberndorfer JM, Achtziger W, Hörnlein HREM (1996) Two approaches for truss topology optimization: a comparison for practical use. Struct Optim 11:137–144

Schittkowski K (1986) NLPQL: A FORTRAN subroutine for solving constrained nonlinear programming problems. Ann Oper Res 5:485–500

Slemp WCH, Bird RK, Kapania RK, Havens D, Norris A, Olliffe R (2011) Design, optimization, and evaluation of integrally stiffened Al-7050 panel with curved stiffeners. J Aircr 48:1163–1175

Miki Man & Cybernetics Conference Smc MBT-IS (1999) A parallel genetic algorithm with distributed environment scheme

ABAQUS Standard User's Manual Version 6.10[M] (2010) Pawtucket: Karlsson and Sorensen Inc.

Stegmann J, Lund E (2005) Discrete material optimization of general composite shell structures. Int J Numer Methods Eng 62:2009–2027

Sun Z, Cui R, Cui T, Liu C, Shi S, Guo X (2020) An optimization approach for stiffener layout of composite stiffened panels based on moving morphable components (MMCs). Acta Mech Solida Sin 33:650–662

Svanberg K (2010) The method of moving asymptotes—a new method for structural optimization. Int J Numer Methods Eng 24:359–373

Wang B, Hao P, Li G, Wang XJ, Tang XH, Luan Y (2014) Generatrix shape optimization of stiffened shells for low imperfection sensitivity. Science China 57:2012–2019

Wang B, Tian K, Zhou C, Hao P, Zheng Y, Ma Y, Wang J (2017) Grid-pattern optimization framework of novel hierarchical stiffened shells allowing for imperfection sensitivity. Aerosp Sci Technol 62:114–121

Wang D, Abdalla MM, Zhang W (2018) Sensitivity analysis for optimization design of non-uniform curved grid-stiffened composite (NCGC) structures. Compos Struct 193:224–236

Wang D, Abdalla MM, Wang Z-P, Su Z (2019) Streamline stiffener path optimization (SSPO) for embedded stiffener layout design of non-uniform curved grid-stiffened composite (NCGC) structures. Comput Methods Appl Mech Eng 344:1021–1050

Wang D, Yeo S-Y, Su Z, Wang Z-P, Abdalla MM (2020) Data-driven streamline stiffener path optimization (SSPO) for sparse stiffener layout design of non-uniform curved grid-stiffened composite (NCGC) structures. Comput Methods Appl Mech Eng 365:113001

Wang B, Zhou Y, Tian K, Wang G (2020) Novel implementation of extrusion constraint in topology optimization by Helmholtz-type anisotropic filter. Struct Multidisc Optim 62:2091–2100

Yan J, Cheng G, Liu L (2008) A Uniform Optimum Material Based Model for Concurrent Optimization of Thermoelastic Structures and Materials. Int J Simul Multidisci Des Optim 2:259–266

Yan J, Duan Z, Lund E, Wang J (2017) Concurrent multi-scale design optimization of composite frames with manufacturing constraints. Struct Multidisc Optim 56:519–533. https://doi.org/10.1007/s00158-017-1750-0

Zhang S, Norato JA (2017) Optimal design of panel reinforcements with ribs made of plates. J Mech Des. https://doi.org/10.1115/1.4036999

Zhang S, Norato JA, Gain AL, Lyu N (2016) A geometry projection method for the topology optimization of plate structures. Struct Multidisc Optim 54:1173–1190. https://doi.org/10.1007/s00158-016-1466-6

Zhang S, Gain AL, Norato JA (2020) Adaptive mesh refinement for topology optimization with discrete geometric components. Comput Methods Appl Mech Eng 364:112930. https://doi.org/10.1016/j.cma.2020.112930

Zhao W, Kapania RK (2016) Buckling analysis of unitized curvilinearly stiffened composite panels. Compos Struct 135:365–382

Zhou Y, Tian K, Xu S, Wang B (2020) Two-scale buckling topology optimization for grid-stiffened cylindrical shells. Thin-Walled Struct 151:106725. https://doi.org/10.1016/j.tws.2020.106725

Zhou M, Fleury R, Shyy Y-K, Thomas H, Brennan J (2002) Progress in topology optimization with manufacturing constraints. 9th AIAA/ISSMO symposium multidisciplinary analysis optimization. American Institute of Aeronautics and Astronautics

Zhu J-H, Gu X-J, Zhang W-H, Beckers P (2013) Structural design of aircraft skin stretch-forming die using topology optimization. J Comput Appl Math 246:278–288

Acknowledgements

This study was funded by the National Natural Science Foundation of China (11772078 and 11825202), the Project supported by Liaoning Provincial Natural Science Foundation (2019-YQ-01), and Liaoning Revitalization Talents Program (XLYC1907142 and XLYC1802020). Moreover, the authors gratefully acknowledge financial support from the China Scholarship Council.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Replication of results

All the key formulas for the calculation have been provided in the article. If the reader is interested, we can provide the Matlab code.

Additional information

Responsible Editor: Graeme James Kennedy

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: The sensitivity analysis of the linear buckling load

Appendix: The sensitivity analysis of the linear buckling load

In this paper, the linear buckling load is calculated with the finite element method by solving the eigenvalue equation as follows.

For the DMO, the sensitivities are necessary. The sensitivities are calculated with the adjoint method, which is briefly derived as follows. The direct approach to obtain the eigenvalue sensitivity in case of a distinct, i.e., the simple eigenvalue \(\lambda_{j}\) is to differentiate Eq. (22) to the design variable \(x_{ij}\) premultiply by \({{\varvec{\Phi}}}_{j}^{T}\) and make use of Eq. (22). Then the following expression can be obtained as

where it has been assumed that the eigenvectors have been \({\mathbf{K}}_{{{\varvec{\upsigma}}}}\) -orthonormalized, such that \({{\varvec{\Phi}}}_{i}^{T} {\mathbf{K}}_{{{\varvec{\upsigma}}}} {{\varvec{\Phi}}}_{i} = 1\). The geometric matrix is an implicit function of the displacement field, i.e., \({\mathbf{K}}_{{{\varvec{\upsigma}}}} = {\mathbf{K}}_{{{\varvec{\upsigma}}}} \left( {{\mathbf{u}}({\mathbf{x),x}}} \right)\), which has to be taken into account as

Then the static equilibrium equation \({\mathbf{K}}{\mathbf{u}}{\mathbf{ = F}}\) is differentiated to the design variable \(x_{ij}\) as

where the load sensitivity \(\partial {\mathbf{F}}/\partial x_{ij}\) is zeros. Then, substituting Eq. (25) into Eq. (24) yields

Thus, the adjoint vector \({{\varvec{\Lambda}}}\) that satisfies Eq. (27) can be introduced.

Finally, substituting the adjoint vector \({{\varvec{\Lambda}}}\) into Eq. (23), the full analytically design sensitivities can be obtained as follows:

Rights and permissions

About this article

Cite this article

Ma, X., Wang, F., Aage, N. et al. Generative design of stiffened plates based on homogenization method. Struct Multidisc Optim 64, 3951–3969 (2021). https://doi.org/10.1007/s00158-021-03070-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-021-03070-3