Abstract

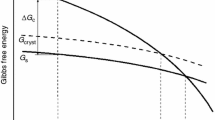

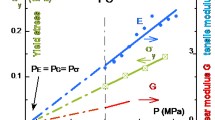

It is well known that the crystallisation and melting behaviour of semicrystalline polymers depends in a pronounced manner on the temperature history. If the polymer is in the liquid state above the melting point, and the temperature is reduced to a level below the glass transition, the final degree of crystallinity, the amount of the rigid amorphous phase and the configurational state of the mobile amorphous phase strongly depend on the cooling rate. If the temperature is increased afterwards, the extents of cold crystallisation and melting are functions of the heating rate. Since crystalline and amorphous phases exhibit different densities, the specific volume depends also on the temperature history. In this article, a thermodynamically based phenomenological approach is developed which allows for the constitutive representation of these phenomena in the time domain. The degree of crystallinity and the configuration of the amorphous phase are represented by two internal state variables whose evolution equations are formulated under consideration of the second law of thermodynamics. The model for the specific Gibbs free energy takes the chemical potentials of the different phases and the mixture entropy into account. For simplification, it is assumed that the amount of the rigid amorphous phase is proportional to the degree of crystallinity. An essential outcome of the model is an equation in closed form for the equilibrium degree of crystallinity in dependence on pressure and temperature. Numerical simulations demonstrate that the process dependences of crystallisation and melting under consideration of the glass transition are represented.

Similar content being viewed by others

References

Demirel B., Yaras A., Elcicek H.: Crystallization behavior of PET materials. BAÜ Fen Bil. Enst Cilt 13(1), 26–35 (2011)

Phang I.Y., Ma J., Shen L., Liu T., Zhang W.: Crystallization and melting behavior of multi-walled carbon nanotube-reinforced nylon-6 composites. Polym. Int. 55, 71–79 (2006)

Wunderlich B.: Thermodynamic description of condensed phases. J. Therm. Anal. Calorim. 102, 413–424 (2010)

Wunderlich B.: Reversible crystallisation and the rigid-amorphous phase in semicrystalline macromolecules. Prog. Polym. Sci. 28, 383–450 (2003)

Menczel J., Wunderlich B.: Heat capacity hysteresis of semicrystalline macromolecular glasses. J. Polym. Sci. Polym. Lett. Ed. 19, 261 (1981)

Cheng S.Z.D., Wunderlich B.: Thermal analysis of poly(butylene terephthalate) for heat capacity, rigid-amorphous content and transition behavior. Macromolecules 21, 2443–2458 (1988)

Cheng S.Z.D., Pan R., Wunderlich B.: Glass transition and melting behavior of poly(ethylene-2,6-naphthalenedicarboxylate). Macromol. Chem. 189, 789–797 (1988)

Huo P., Cebe P.: Effects of thermal history on the rigid amorphous phase in poly(phenylene sulfide). Colloid Polym. Sci. 270, 652–840 (1992)

Alsleben M., Schick C.: The melting of polymers - a three-phase approach. Thermochim. Acta 238, 203–227 (1994)

Song M., Hourston D.J.: Temperature-modulated scanning calorimetry: some comments on the rigid amorphous fraction in semicrystalline poly(ethylene terephthalate). J. Therm. Anal. 54, 651–657 (1998)

Xu H., Ince B.S., Cebe P.: Development of the crystallinity and rigid amorphous fraction in cold-crystallized isotactic polystyrene. J. Polym. Sci. 41, 3026–3036 (2003)

Arnoult M., Dargent E., Mano J.F.: Mobile amorphous phase fragility in semi-crystalline polymers: comparison of PET and PLLA. Polymer 48, 1012–1019 (2007)

Schick C., Wurm A., Mohamed A.: Vitrification and devitrification of the rigid amorphous fraction of semicrystalline polymers revealed from frequency-dependent heat capacity. Colloid. Polym. Sci. 279, 800–806 (2001)

Schick C.: Differential scanning calorimetry (DSC) of semicrystalline polymers. Anal. Bioanal. Chem. 395, 1589–1611 (2009)

Zhuravlev E., Schmelzer J.W.P., Wunderlich B., Schick C.: Kinetics of nucleation and crystallization in poly(ɛ-caprolactone) (PCL). Polymer 52, 1983–1997 (2011)

Xu H., Cebe P.: Heat capacity study of isotactic polystyrene: dual reversible crystal melting and relaxation of rigid amorphous fraction. Macromolecules 37, 2797–2806 (2004)

Piccarolo S., Brucato Y., Kiflie Z.: Non-isothermal crystallization kinetics of PET. Polym. Eng. Sci. 40, 1263–1272 (2000)

Dlubek G., Sen Gupta A., Pionteck J., Häßler R., Krause-Rehberg R., Kaspar H., Lochhaus K.H.: Glass transition and free volume in the mobile (MAF) and rigid (RAF) amorphous fractions of semicrystalline PTFE: a positron lifetime and PVT study. Polymer 40, 6075–6089 (2005)

Wurm, A.: Das Verhältnis von irreversiblen und reversiblen Prozessen während des Kristallisierens und Schmelzens von Polymeren, Dissertation, University of Rostock (2001)

Strobl G.: Laws controlling crystallization and melting in bulk polymers. Rev. Modern Phys. 81, 1287–1300 (2009)

Strobl G.: Crystallization and melting of bulk polymers: new observations, conclusions and a thermodynamic scheme. Prog. Polym. Sci. 31, 398–442 (2006)

Strobl G.: A thermodynamic multiphase scheme treating polymer crystallization and melting. Eur. Phys. J. E 18, 295–309 (2005)

Dietz W.: Sphärolithwachstum in Polymeren. Coll. Polym. Sci. 259, 413–429 (1981)

Avrami M.: Kinetics of phase change. II. Transformation time relations for random distribution of nuclei. J. Chem. Phys. 8, 212–224 (1940)

Banks W., Sharples A.: The AVRAMI equation in polymer crystallization. Die Makromolekulare Chemie 59, 233–236 (1963)

Sorrentino, L., Iannace, S., Di Maio, E., Acierno, D.: Isothermal crystallization kinetics of chain extended PET. J. Polym. Sci. B Polym. Phys. 1966–1972 (2005)

Lu X.F., Hai J.N.: Isothermal crystallization kinetics and melting behaviour of poly(ethylene terephthalate). Polymer 42, 9423–9431 (2001)

Nakamura K., Watanabe T., Katayama K., Amano T.: Some aspects of nonisothermal crystallization of polymers. I. Relationship between crystallization temperature, crystallinity, and cooling conditions. J. Appl. Polym. Sci. 16, 1077–1091 (1972)

Ruitenberg G., Woldt E., Petford-Long A.K.: Comparing the Johnson–Mehl–Avrami–Kolmogorov equations for isothermal and linear heating conditions. Thermochim. Acta 378, 97–105 (2001)

Malkin A.YA., Beghishev V.P., Keapin I.A., Andrianova Z.S.: General treatment of polymer crystallization kinetics—part 1. A new macrokinetic equation and its experimental verification. Polym. Eng. Sci. 24, 1396–1401 (1984)

Malkin A.YA., Beghishev V.P., Keapin I.A., Andrianova Z.S.: General treatment of polymer crystallization kinetics—part 2. The kinetics of nonisothermal crystallization. Polym. Eng. Sci. 24, 1402–1408 (1984)

Krigbaum W.R.: Structure and physical properties of crystalline polymers. J. Polym. Sci. Part C 15, 251–262 (1966)

Piccarolo S., Saiu M., Brucato V., Titomanilo G.: Crystallization of polymer melts under fast cooling. II. High-purity iPP. J. Appl. Polym. Sci. 46, 625–634 (1992)

Shardakov I., Golotina L.: Modeling of deformation processes in semicrystalline polymers with allowance for the glass transition in the amorphous phase. J. Mater. Sci. Eng. B 1, 703–709 (2011)

Boyce M.C., Socrate S., Llana P.G.: Constitutive model for the finite deformation stress-strain behavior of poly (ethylene terephthalate) above the glass transition. Polymer 41, 2183–2201 (2000)

Thien-Nga, L., Guilie, J., Le Tallec, P.: Thermodynamic model for strain-induced crystallisation in rubber. In: Eberhardsteiner, J., et al. (eds.) European Congress on Computational Methods in Applied Sciences and Engineering (ECCOMAS 2012), Austria, 10–14 September (2012)

Ahzi S., Makradi A., Gregory R.V., Eddie D.D.: Modeling of deformation behavior and strain-induced crystallization in poly(ethylene terephthalate) above the glass transition temperature. Mech. Mater. 35, 1139–1148 (2003)

Chevalier L., Marco Y.: Identification of a strain induced crystallisation model for PET under uni- and bi-axial loading: influence of temperature dispersion. Mech. Mater. 39, 596–609 (2007)

Yang, Z.J., Harkin-Jones, E.M.A., Armstrong, C.G., Menary, G.H.: Finite element modelling of stretch-blow moulding of PET bottles using Buckley model: plant tests and effects of process conditions and material parameters. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 218, 237–250

Luo Y.M., Chevalier L., Utheza F., Monteiro E.: Numerical simulation of the thermodependant visco hyperelastic behavior of polyethylene terephthalate near the glass transition temperature: prediction of the self-heating during biaxial tension test. Polym. Eng. Sci. 53, 2683–2695 (2013)

Rao I.J., Rajagopal K.R.: A study of strain-induced crystallization of polymers. Int. J. Solids Struct. 38, 1149–1167 (2001)

Rao I.J., Rajagopal K.R.: A thermodynamic framework for the study of crystallization in polymers. Z. Angew. Math. Phys. 53, 365–406 (2002)

Dusunceli N., Colak O.U.: Modelling effects of degree of crystallinity on mechanical behavior of semicrystalline polymers. Int. J. Plast. 24, 1224–1242 (2008)

Mrabet L., Rahouadi R., Cunat C.: An irreversible thermodynamic model for semicrystalline polymers submitted to multisequence loading at large strain. Polym. Eng. Sci. 45, 42–51 (2005)

Sanchez I.C., Eby R.K.: Thermodynamics and crystallization of random copolymers. Macromolecules 8, 638–641 (1975)

Sanchez I.C., Eby R.K.: Crystallization of random copolymers. J. Res. Natl. Bureau Stand. Phys. Chem. 77, 353–358 (1973)

Müller I.: Grundzüge der Thermodynamik. Springer Publikation House, (2001)

Haupt P.: Continuum mechanics and theory of materials. Springer publication house, (2002)

Lion A., Dippel B., Liebl C.: Thermomechanical material modelling based on a hybrid free energy density depending on pressure, isochoric deformation and temperature. Int. J. Solids Struct. 51, 729–739 (2014)

Lion A., Engelhardt M., Johlitz M.: Thermomechanical and calorimetric behaviours of supported glass-forming films: a study based on thermodynamics with internal variables. Thin Solid Films 522, 441–451 (2012)

Lion A., Liebl C., Kolmeder S., Peters J.: Representation of the glass-transition in mechanical and thermal properties of glass-forming materials: a three-dimensional theory based on thermodynamics with internal state variables. J. Mech. Phys. Solids 58, 1338–1360 (2010)

Lion A., Yagimli B.: On the frequency-dependent specific heat and TMDSC: constitutive modelling based on thermodynamics with internal state variables. Thermochim. Acta 490, 64–74 (2009)

Lion A., Peters J.: Coupling effects in dynamic calorimetry: frequency-dependent relations for specific heat and thermomechanical responses—a one-dimensional approach based on thermodynamics with internal state variables. Thermochim. Acta 500, 76–87 (2010)

Zhou, Q., Binetruy, C., Burtin, C., Poitou, A.: A dynamic method for the residual stress measurement during polymer crystallization. Exp. Mech. (2014). doi:10.1007/s11340-014-9909-8

Williams M.L., Landel R.F., Ferry J.D.: The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids. J. Am. Chem. Soc. 77, 3701–3707 (1955)

Varma-Nair M., Wunderlich B.: Heat capacity and other thermodynamic properties of linear macromolecules X. Update of the ATHAS 1980 Data Bank. J. Phys. Chem. Ref. Data 20, 249–404 (1991)

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Andreas Öchsner

Rights and permissions

About this article

Cite this article

Lion, A., Johlitz, M. A thermodynamic approach to model the caloric properties of semicrystalline polymers. Continuum Mech. Thermodyn. 28, 799–819 (2016). https://doi.org/10.1007/s00161-015-0415-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-015-0415-8