Abstract

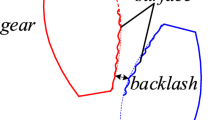

The modelling of a one-stage spur gear transmission by a two degrees of freedom system produces two modes: rigid body and elastic. The time varying meshing stiffness is the main internal excitation source for the transmission and governs the behaviour of the elastic mode. Deterioration of one or several teeth, which affects the gear mesh stiffness, is considered in this work. The beginning of crack or spalling are modelled respectively by tooth having localised and distributed defect and are taken into account in the model. Simulation results are analysed by cepstrum and spectrum techniques. It is found that cepstrum and spectrum techniques are very efficient for localised and distributed defects, respectively. Series of tests are made in the experimental setup. Spectrum and cepstrum analysis of the recorded responses, with and without defects, are compared with numerical results and confirms their usefulness in gear monitoring .

Similar content being viewed by others

References

Bigret R, Freon JL (1995) Diagnostic - maintenance - disponibilité des machines tournantes. Edition Masson

Capdessus C, Sidahmed M (1992) Analyse des vibrations d’un engrenage : cepstre, corrélation, spectre. Traitement du signal 8(5):365–372

Lebold M, McClintic K, Cambell R, Byington C, Maynard K (2000) Review of vibration analysis methods for gearbox diagnostics and prognostics. Proceedings of the 54th Meeting of the Society for Machinery Failure Prevention Technology, Virginia Beach, VA, 1–4 May 2000

Sidahmed M (1990) Détection précoce des défauts d’engrenages par analyse vibratoire. 4ième journées d’études transmissions mécaniques, ECAM Lyon, June 1990

Bouillaut L (2000) Approches cyclostationnaire et bilinéaire pour l’analyse vibratoire de machines tournantes: Approches théoriques et applications au diagnostic. Dissertation, l’Université de technologie de Compiègne

Miller AJ (1999) A new wavelet basis for the decomposition of gear motion error signals and its application to gearbox diagnostics. Dissertation, Pennsylvania University

El Badaoui M, Guillet F, Daniere J (1999) Surveillance des systèmes complexes a engrenages par l’analyse cepstrale synchrone. Traitement du signal 16(5):371–381

Randall RB (1977) Cepstrum analysis and gearbox defect diagnosis, 1st edn. Bruel and Kjaer application note

Merzoug M, Miloudi A, Brahimi K (2001) Comportement dynamique d’une transmission par engrenages – Analyse de la stabilité. XVème Congrès Français de Mécanique, Nancy, France 3–7 September 2001

Haddar M, Ben Amar M, Gafsi W, Maalej A (2000) Analyse du comportement dynamique et tribologique d’une transmission à engenrages droits en présence d’un défaut de parallélisme. 3ième journées de mécanique et ingénierie. Sfax, 28–30 March 2000

Begg CD, Byington CS, Maynard KP (2000) Dynamic simulation of mechanical defect transition. Proceedings of the 54th Meeting of the Society for Machinery Failure Prevention Technology, Virginia Beach, VA, 1–4 May 2000

Dalpiaz G, Rivola A, Rubini R (1996) Dynamic modeling of gear systems for condition monitoring and diagnostics. Congress on Technical Diagnostics

Haddar M (1998) Réponse dynamique d’une boite de vitesse, Revue internationale d’ingénierie des systèmes de productions mécanique. November 1998, pp V29–V34

Velex P (1988) Contribution à l’analyse du comportement dynamique des engrenages à axes parallèles. Dissertation, Inst. Nat. Des sciences appliquées de Lyon

Rigaud E (1999) Modeling and analysis of static transmission error-effect of wheel deformation and interactions between adjacent loaded teeth. Laboratoire de tribologie et dynamique des systèmes, Ecole centrale de Lyon

Dhatt G, Touzot G (1984) Une présentation de la méthode des éléments finis. Edition Maloine

Remmers EP (1978) Gear mesh excitation spectra arbitrary tooth spacing errors. Load and design contact ratio. J Mech Des Trans ASME 100:715–720

Maynard KP (1999) Interstitial processing: the application of noise processing gear fault detection. Proceedings of the international conference on condition monitoring, University of Wales Swansea, UK, 12 April 1999, p 77–86

Henriot G (1985) Traité théorique et pratique des engrenages, vol 1 and 2. Edition Dunod Technique

Beeg CD, Byington CS, Maynard KP (2000) Dynamic simulation of mechanical fault transition. Proceedings of the 54th Meeting of the Society for Machinery Failure Prevention Technology, Virginia Beach, VA, 1–4 May 2000

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fakhfakh, T., Chaari, F. & Haddar, M. Numerical and experimental analysis of a gear system with teeth defects. Int J Adv Manuf Technol 25, 542–550 (2005). https://doi.org/10.1007/s00170-003-1830-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-1830-8