Abstract

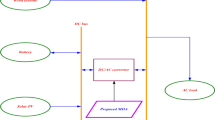

A simulation system with the approach of multi-pass and genetic algorithm (MPGA) is developed for dispatching dual commands by a stacker machine in a unit-load/class-based automated storage and retrieval system (AS/RS). Three single-rules, FCFS/STT, SDT/STT, and STTbk, are run individually by a single-pass simulation and served as the benchmarks to compare with the performances of three kinds of the MPGA approach. All experiments, singles and MPGA, start with the same initial system states and run with the same input data streams. Due to a larger solution space for the optimal search and an iterative searching method, the MPGA approach greatly improves the performances of our AS/RS model, compared with traditional approaches.

Similar content being viewed by others

References

Schwarz LB, Graves SC, Hausman WH (1978) Scheduling policies for automatic warehousing systems: simulation results. AIIE Trans 10(3):260–270

Han MH, McGinnis LF, Shieh JS, White JA (1987) On sequence retrievals in an automated storage/retrieval system. IIE Trans March 56–66

Raliff HD, Rosenthal AS (1983) Order-picking in a rectangular warehouse: a solvable case of the traveling salesman problem. Oper Res 31(3):507–521

Boser YA, Scorn EC, Sharp GP (1990) Geometric approaches to solve the Chebyshev traveling salesman problem. IIE Trans 22(3):238–254

Lee HF, Schaefer SK (1996) Retrieval sequence for unit-load automated storage and retrieval systems with multiple openings. Int J Prod Res 34(10):2943–2962

Lee HF (1997) Performance analysis for automated storage and retrieval systems. IIE Trans 29:15–18

van den Berg JP, Gademann AJRM (1999) Optimal routing in an automated storage/retrieval system with dedicated storage. IIE Trans 31:407–415

Linn RJ, Wysk RA (1987) An analysis of control strategies for an automated storage/retrieval system. INFOR 25(1):66–83

Linn RJ, Wysk RA (1990) An expert system based controller for an automated storage/retrieval system. Int J Prod Res 28(4):735–756

Linn RJ, Wysk RA (1990) An expert system framework for automated storage and retrieval system control. Computer Ind Eng 18(1):37–48

Wang JY, Yih Y (1997) Using neural networks to select a control strategy for automated storage and retrieval system (AS/RS). Int J Comput Integ Manuf 10(6):487–495

van den Berg JP, Gademann AJRM (2000) Simulation study of an automated storage/retrieval system. Int J Prod Res 38(6):1339–1356

Wang CS, Uzsoy R (2002) A generic algorithm to minimize maximum lateness on a batch processing machine. Comput Oper Res 29:1621–1640

Armentano VA, Mazzini R (2000) A genetic algorithm for scheduling on a single machine with set-up times and due dates. Prod Plan Control 11(7):713–720

Liao LM, Liao CJ (2002) A Tuba search approach for single machine scheduling with major and minor setups. Int J Ind Eng 9(2):174–183

Yen PC, Wan G (2003) Single machine bicriteria scheduling: a survey. Int J of Ind Eng 10(3):222–231

Morton TE, Pentico DW (1993) Heuristic scheduling systems with applications to production systems and project management. Wiley, New York, pp 403–404

Fu HP, Su CT (2000) A comparison of search techniques for minimizing assembly time in printed wiring assembly. Int J Prod Econ 63:83–98

Harmonosky CM (1990) Implementation issues using simulation for real-time scheduling, control, and monitoring. Proc 1990 Winter Simulation Conf, pp 595–598

Harmonosky CM, Robohn SF (1995) Investigating the application potential of simulation to real-time control decisions. Int J Comput Integr Manuf 8(2):126–132

Wu SD, Wysk RA (1988) Multi-pass expert control system – a control/scheduling structure for flexible manufacturing cells. J Manuf Syst 7(2):107–120

Son YJ, Rodriguez-Rivera H, Wysk RA (2000) A multi-pass simulation-based, real-time scheduling and shop floor control system. Transactions 16(4):159–172

Wu SD, Wysk RA (1989) An application of discrete-event simulation to on-line control and scheduling in flexible manufacturing. Int J Prod Res 27(9):1603–1623

Cho HR, Wysk RA (1993) A robust adaptive scheduler for an intelligent workstation controller. Int J Prod Res 31(4):771–789

Cho HR, Smith JS, Wysk RA (1997) An intelligent workstation controller for integrated planning and scheduling of an FMS cell. Prod Plan Control 8(6):597–607

Murlidharan B, Linn RJ, Pandit R (1995) Shuffling heuristics for the storage location assignment in an AS/RS. Int J Prod Res 33(6):1661–1672

van den Berg JP, Gademann AJRM (1999) Optimal routing in an automated storage/retrieval system with dedicated storage. IIE Trans 31:407–415

Pan CH, Wang CH (1996) A framework for the dual command cycle travel time model in automated warehousing systems. Int J Prod Res 34(8):2099–2117

Yin YL, Rau H (2005) Dynamic selection of sequencing rule for a class-based unit-load automated storage and retrieval system. Int J Adv Manuf Tech DOI:10.1007/s00170-005-0005-1

Subramaniam V (2000) Dynamic selection of dispatching rules for job shop scheduling. Prod Plan Control 11(1):73–81

Acknowledgements

The authors would like to thank the Editors and the anonymous referees for their valuable comments and suggestions on improving the quality of this paper. This work is supported in part by National Science Council of Republic of China under the grant NSC 94-2213-E-033-006.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rau, H., Yin, YL. Dual commands dispatching of a class-based unit-load automated storage and retrieval system using multi-pass simulation with generic algorithm. Int J Adv Manuf Technol 33, 530–539 (2007). https://doi.org/10.1007/s00170-006-0478-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0478-6