Abstract

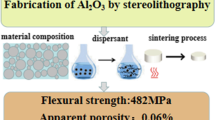

A soft moulding process for manufacture of ceramic microcomponents, alumina and Al2O3/SiC composite, is introduced in this paper. The process involves fabrication of SU-8 master moulds and production of mirrored polydimethysiloxane (PDMS) soft moulds. Green parts are formed in the PDMS moulds by filling the ceramic slurry into the soft moulds and net-shape green components are obtained after demoulding. The methods for the mould filling using different suspensions were demonstrated: one was aqueous suspension for alumina microcomponent and another was non-aqueous suspension for Al2O3/SiC microcomponent. The measurements showed that the proposed soft lithography process is successful in producing ceramic microcomponents and retaining the fine features in micron scale.

Similar content being viewed by others

References

Burns DM, Bright VM (1999) Sens Actuators A Phys 70:6. doi:10.1016/S0924-4247(98)00106-X

Rossi C, Esteve D, Mingues C (1999) Sens Actuators A Phys 74:211. doi:10.1016/S0924-4247(98)00319-7

Ducheyne P (1987) J Biomed Mat Res 21:219–236 August

Slivinski IG, Braurman EG (1960) Glass Ceramics 15(10):571–572. doi:10.1007/BF00667135

Seraji S, Wu Y, Larson NE, Cao GH (2000) Adv Mater 12:1421. doi:10.1002/1521-4095(200010)12:19<1421::AID-ADMA1421>3.0.CO;2-4

Schönholzer UP, Gauckler LJ (1999) Adv Mater 11:630. doi:10.1002/(SICI)1521-4095(199906)11:8<630::AID-ADMA630>3.0.CO;2-Y

Heule M, Gauckler LJ (2001) Adv Mater 13:1790. doi:10.1002/1521-4095(200112)13:23<1790::AID-ADMA1790>3.0.CO;2-C

Kim JS, Jiang K, Chang I (2006) J Micromech Microeng 16:48. doi:10.1088/0960-1317/16/1/007

Jin P, Jiang KC, Sun NJ, Microlith J (2004) Microfab. Microsyst 3:569

Jiang K, Lancaster MJ, Jin P (2005) J Micromech Microeng 15:1522. doi:10.1088/0960-1317/15/8/021

Zhu ZG, Wei XY, Jiang K (2007) J Micromech Microeng 17:193. doi:10.1088/0960-1317/17/2/002

Zhang D, Su B, Button TM (2004) J Eur Ceram Soc 24:231. doi:10.1016/S0955-2219(03)00241-3

KiON (2005) Technical Bulletins 1

Lee CH, Jiang K, Davies GJ (2007) Mater Charact 58:603. doi:10.1016/j.matchar.2006.07.005

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, Z., Hassanin, H. & Jiang, K. A soft moulding process for manufacture of net-shape ceramic microcomponents. Int J Adv Manuf Technol 47, 147–152 (2010). https://doi.org/10.1007/s00170-008-1864-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1864-z