Abstract

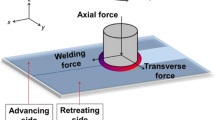

The paper presents the results of an experimental investigation, done on the friction stir welding (FSW) plunging stage. Previous research works showed that the axial force and torque generated during this stage were characteristic for a static qualification of a FSW machine. Therefore, the investigation objectives are to better understand the relation between the processing parameters and the forces and torque generated. One of the goals is to find a way to reduce the maximum axial force and torque occurring at the end of the plunging stage in order to allow the use of a flexible FSW machine. Thus, the influence of the main plunge processing parameters on the maximum axial force and torque are analysed. In fact, forces and torque responses can be influenced by the processing parameter. At the end, a diagram presenting the maximum axial force and torque according to the processing parameters is presented. It is an interesting way to present the experimental results. This kind of representation can be useful for the processing parameters choice. They can be chosen according to the force and torque responses and consequently to the FSW machine capacities.

Similar content being viewed by others

References

Thomas WM, Nicholas ED., Needham JC, Murch MG, Templemith P, Dawes CJ (1991) Patent Application No. 9125978.8

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50:1–78

Arbegast WJ (2007) Friction stir welding and processing (Chapter 13). ASM International, Materials Park, OH, ISBN-13978-0-87170-840-3

Zimmer S, Langlois L, Laye J, Goussain JC, Martin P, Bigot R (2008) Methodology for qualifying a friction stir welding equipment. Proceedings of the 7th International Symposium on Friction Stir Welding, Awaji Island, Japan

Lienert TJ, Stellwag WL,. Grimmett BB, Warke RW (2003) friction stir welding studies on mild steel. Supplement to the Welding Journal, January 2003

Mandal S, Rice J, Elmustafa AA A (2008) Experimental and numerical investigation of the plunge stage in friction stir welding. J Mat Process Technol 203:411–419

Fourment L, Guerdoux S (2008) 3D numerical simulation of the three stages of friction stir welding based on friction parameters calibration. Int J Mater Form Suppl 1:1287–1290

Zhang Z, Zhang ZW (2007) Numerical studies on effect of axial pressure in friction stir welding. Sci Technol Weld Join 12(3):226–24

Santella M, Grant G, Arbegast W (2003) Plunge testing to evaluate tool materials for friction stir welding of 6061 + 20wt%Al2O3 composite. Proceedings of the 4th International Symposium on Friction Stir Welding, Part City, USA

Gerlich A, Su P, North TH (2005) Tool penetration during friction stir spot welding of Al and Mg alloys. J Mater Sci 40:6473–6481

Zaeh MF, Eireiner D, Papadakis L (2005) Friction stir welding with modern milling machines. Requirements, Approach and Application. Proceedings of the 5th International Symposium on Friction Stir Welding, Metz, France

Soundararajan V, Zekovic S, Kovacevic R (2005) Thermo-mechanical model with adaptive boundary conditions for friction stir welding of Al 6061. Int J Mach Tools Manuf 45:1577–1587

Arora A, Nandan R, Reynolds AP, Debroy T (2009) Torque, power requirement and stir zone geometry in friction stir welding through modeling and experiments. Scr Mater 60:13–16

Zhang Z, Zhang ZW (2007) Numerical studies of preheating time effect on temperature and material behaviours in friction stir welding process. Sci Technol Weld Join 12(5):436–448

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zimmer, S., Langlois, L., Laye, J. et al. Experimental investigation of the influence of the FSW plunge processing parameters on the maximum generated force and torque. Int J Adv Manuf Technol 47, 201–215 (2010). https://doi.org/10.1007/s00170-009-2188-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2188-3