Abstract

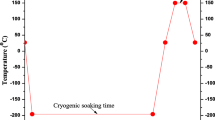

Cryoprocessing, a supplementary process to conventional heat treatment process, is the process of deep-freezing materials at cryogenic temperatures to enhance the mechanical and physical properties of materials being treated. The execution of cryoprocessing on cutting tool materials increases wear resistance, hardness, and dimensional stability and reduces tool consumption and down time for the machine tool set up, thus leading to cost reductions. The effects of cryoprocessing on tool steels and carbides, metallurgical aspects including reduced amount of retained austenite, precipitation of η-carbides, phase change in carbides, improvement in wear resistance, and applications are reviewed for manufacturing industry. Although it has been confirmed that cryogenic processing can improve the service life of tools, the degree of improvement experienced and the underlying mechanism remains ambiguous. The steps involved in cryoprocessing are critical enough to account for the significant incongruity in post-treated performance.

Similar content being viewed by others

References

Brown J (1995) Big chill to extend gear life. Power Transm Des 59 (September)

Sweeney TP Jr (1986) Deep cryogenics: the great cold debate. Heat Treat 18(2):28–32 (February)

Stratton PF (2007) Optimising nano-carbide precipitation in tool steels. Mater Sci Eng A 449-451:809–812

Wilkins C (1999) Cryogenic processing; the big chill. EDM Today 36–44 (May/June)

Kamody DJ (1999) Cryogenics process update. Adv Mater Process 155(6):H67–H69 (June)

Popandopulo N, Zhukova LT (1980) Transformation in high speed steels during cold treatment. Met Sci Heat Treat 22(10):708–710

Carlson EA (1990) Cold Treating and Cryogenic Treatment of Steel in ASM Handbook, vol. 4 Heat Treating, ASM International, 10th Ed., Metals Park, OH, pp 203–206

Preciado M, Bravo PM, Alegre JM (2006) Effect of low temperature tempering prior cryogenic treatment on carburized steels. J Mater Process Technol 176(1–3):41–44

Mohan Lal D, Renganarayanan S, Kalanidhi A (2001) Cryogenic treatment to augment wear resistance of tool and die steels. Cryogenics 41(3):149–155

Molinari A, Pellizzari M, Gialanella S, Straffelini G, Stiasny KH (2001) Effect of deep cryogenic treatment on the mechanical properties of tool steels. J Mater Process Technol 118(1–3):350–355

Meng F, Tagashira K, Sohma H (2004) Wear resistance and microstructure of cryogenic treated Fe–1.4Cr–1C bearing steel. Scr Metall Mater 31:865–868

Kamody DJ. US Patent 5,259,200, 9 November 1993

Moore K, Collins DN (1993) Cryogenic treatment of three heat treated tool steels. Key Eng Mater 86&87:47–54

Zurecki Z (2006) Cryogenic quenching of steel revisited. ASM Proceedings: Heat Treating, pp 106–113

Alexandru G, Ailincai C, Baciu (1990) Influence of cryogenic treatments on life of alloyed high speed steels. Mém Étud Sci Rev Métall 4:283–388

Yun D, Xiaoping L, Hongshen X (1998) Deep cryogenic treatment of high-speed steel and its mechanism. Heat Treat Met 3:55–59

Dymchenko VV, Safronova VN (1993) Refrigeration treatment of quenched roll steel. Tyazheloe Mashinostroenie (9):29–32

Vimal AJ, Bensley A, Lal DM, Srinivasan K (2008) Deep cryogenic treatment improves wear resistance of En 31 steel. Mater Manuf Process 23(4):369–376

da Silva FJ, Franco SD, Machado AR, Ezugwu EO, Souza AM Jr (2006) Performance of cryogenically treated HSS tools. Wear 261(5–6):674–685

Gill SS, Singh R, Singh H, Singh J (2008) Wear behaviour of cryogenically treated tungsten carbide inserts under dry and wet turning conditions. Int J Mach Tools Manuf 49(3–4):256–260

Kalin M, Leskovsek V, Vizintin J (2006) Wear behavior of deep cryogenic treated high speed steel at different loads. Mater Manuf Process 21:741–746

Wojcieszynski AL (1999) Cryogenic treatment a mystery or misery of heat treatment. ASM Proceedings: Heat Treating, pp 237–243

Gill SS, Singh R, Singh H (2007) Sub zero treatment of steels. Proceedings of National Conference on Futuristic Trends in Mechanical Engineering (NCFTME 2007) at SUSCET Tangori (Pb), India, pp 242–250

Collins DN, O'Rourke G (1998) The response of tool steels to deep cryogenic treatment effect of alloying elements. ASM Proceedings: Heat Treating, pp 229–247

Darwin JD, Mohan Lal D, Nagarajan G (2007) Optimization of cryogenic treatment to maximize the wear resistance of Chrome Silicon spring steel by Taguchi method. Int J Mat Sci 2(1):17–28

Darwin JD, Mohan Lal D, Nagarajan G (2008) Optimization of cryogenic treatment to maximize the wear resistance of 18% Cr martensitic stainless steel by Taguchi method. J Mater Process Technol 195(1–3):241–247

Barron RF (1996) In: Proceedings of the Conference of Manufacturing Strategies, vol 6, Nashville, pp 137

Barron RK (1974) Cryogenic treatment produces cost savings for slitter knives. TAPPI J 57(5):137 (May)

Holm T (1997) Cryotreatment—state of the art—an update. AGA Internal Report

Collins DN, Dormer J (1997) Deep cryogenic treatment of a D2 cold-worked tool steel. Heat Treat Met 3:71–74

Hallum DL (1996) Cryogenic tempering delivers better cutting tool durability. Am Mach, pp 140-142 (May)

Zhirafar S, Rezaeian A, Pugh M (2007) Effect of cryogenic treatment on the mechanical properties of 4340 steel. J Mater Process Technol 186(1–3):298–303

Bensely A, Senthilkumar D, Mohan Lal D, Nagarajan G, Rajadurai A (2007) Effect of cryogenic treatment on tensile behavior of case carburized steel-815M17. Mater Charact 58(5):485–491

Delaye JM, Limoge YJ (1993) Molecular dynamic study of vacancy like defects in a model glass: dynamical behaviour and diffusion. J Phys (Paris) 2:2079-2097

Dobbins DB (1995) Cryogenic treatment can boost life. Metalforming, pp 29 (May)

Bensely A, Venkatesh S, Mohan Lal D, Nagarajan G, Rajadurai A, Junik K (2008) Effect of cryogenic treatment on distribution of residual stress in case carburized En 353 steel. Mater Sci Eng A 479(1):229–235

Das D, Dutta AK, Toppo V, Ray KK (2007) Effect of deep cryogenic treatment on the carbide precipitation and tribological behavior of D2 steel. Mater Manuf Process 22(4):474–480

Jinyong X, Yanping L, Jianzhong W, Xiaoyun K, Yuan G, Zhong X (2007) A study on double glow plasma surface metallurgy Mo–Cr high speed steel of carbon steel. Surf Coat Technol 201:5093–5096

Collins DN (1996) Deep cryogenic treatment of tool steels—a review. Heat Treat Met 23(2):40–42

Collins DN (1998) Cryogenic treatment of tools steels. Adv Mater Process 154(6):H23

Lomte SV, Chikalthankar SB (2007) Investigation of the influence of deep cryogenic treatment on residual stresses in HCHC D2 steels using X-ray diffraction. Proceedings of the AIST Steel Properties and Applications Conference, pp 959–972

Das D, Dutta AK, Ray KK (2009) Influence of varied cryotreatment on the wear behavior of AISI D2 steel. Wear 266(1–2):297–309

Gulyaev AP (1937) Improved methods of heat treating high speed steels to improve the cutting properties. Metallurgy (12):65

Reddy TVS, Ajaykumar BS, Reddy MV, Venkataram R (2007) Improvement of tool life of cryogenically treated P-30 tools. Proceedings of International Conference on Advanced Materials and Composites (ICAMC-2007) at the National Institute for Interdisciplinary Science and Technology, CSIR, Trivandrum, India, pp 457–460

Bensely A, Prabhakaran A, Mohan Lal D, Nagarajan G (2005) Enhancing the wear resistance of case carburized steel (En 353) by cryogenic treatment. Cryogenics 45(12):747–754

Barron RF (1982) Cryogenic treatments on metals to improve wear resistance. Cryogenics 22:409–414

Barron RF (1974) Do treatment at temperature below −120°F help increase the wear resistance of tool steels? Here are some research findings that indicate they do. Heat Treat 14–17 (June)

Seah KHW, Rahman M, Yong KH (2003) Performance evaluation of cryogenically treated tungsten carbide cutting tool inserts. Proc IME B J Eng Manufact 217:29–43

Leskovsek V, Kalin M, Vizintin J (2006) Influence of deep cryogenic treatment on wear resistance of vacuum heat-treated HSS. Vacuum 80:507–518

Meng F, Tagashira K, Azuma R, Sohma H (1994) Role of eta-carbide precipitations in the wear resistance improvements of Fe–12Cr–Mo–V–1.4C tool steel by cryogenic treatment. ISIJ Int 34:205–210

Barron RF (1980) Dry cryogenic treatment increases machine tool life. Boxboard containers international. PRIMEDIA Business Magazines & Media Inc., pp 27 (May)

Sasinowski N. Dimensional tolerances and gauging for tooling in the can-making industry. SME Technical Paper, MR 74–945

Frey R (1983) Cryogenic treatment improves properties of drills and P/M parts. Ind Heat 50(9):21–23

Kosmowski M (1981) The Carbide and Tool Journal, Nov/Dec

Paulin P (1993) Frozen gears. Gear Technol 10:26–29

Chandler H (1995) Heat treater's guide: practices and procedures for irons and steels. ASM International, 2nd Ed., Metals Park, OH, pp 12

Stojko A (2001) Sub-zero treatment of tool steels. M.Sc. thesis, Technical University of Denmark, DTU Department of Manufacturing Engineering and Management, 24 September

Miller PC (1980) Tooling & Production 82, February

Reitz W, Pendray J (2001) Cryoprocessing of materials: a review of current status. Mater Manuf Process 16(6):829–840

Li S, Chen C, Li X, Yuan Z, Liu X (2000) Effect of cryogenic treatment on the abrasive resistance of T12 steel. Mocaxue Xuebao 20(4):276–279

Pellizzari M, Molinari A, Girardini L, Maldarelli L (2008) Deep cryogenic treatment of AISI M2 high-speed steel. Int J Microstruct Mater Prop 3(2–3):383–390

Firouzdor V, Nejati E, Khomamizaden F (2008) Effect of deep cryogenic treatment on wear resistance and tool life of M2 HSS drill. J Mater Process Technol 206(1–3):467–472

Babu PS, Rajendran P, Rao KN (2005) Cryogenic treatment of M1, EN19, and H13 tool steels to improve wear resistance. J Inst Eng India MM 86:64–66

Yong AYL, Seah KHW, Rahman M (2007) Performance of cryogenically treated tungsten carbide tools in milling operations. Int J Adv Manuf Technol 32:638–643

Yong AYL, Seah WKH, Rahman M (2006) Performance evaluation of cryogenically treated tungsten carbide tools in turning. Int J Mach Tools Manuf 46:2051–2056

Quek TW. Machining of steel using cryogenically treated cutting tool inserts. Ph.D. thesis, National University of Singapore, Singapore

Kao M (1984) The effect of cryogenic treatment of sintered tungsten carbide. Master's thesis, Arizona State University

Reddy TVS, Sornakumar T, Reddy MV, Venkatram R (2009) Machinability of C45 steel with deep cryogenic treated tungsten carbide cutting tool inserts. Int J Refract Met Hard Mater 27(1):181–185

Vadivel K, Rudramoorthy R (2008) Performance analysis of cryogenically treated coated carbide inserts. Int J Adv Manuf Technol 42(3–4):222–232

Kim D, Ramulu M (2004) Cryogenically treated carbide tool performance in drilling thermoplastic composites. Trans North Am Manuf Res Inst SME 32:79–85

Hann SK, Gates JD (1997) Transformation toughening white cast iron. J Mater Sci 32:1249–1259

Yang HS, Wang J, Shen BL, Liu HH, Gao SJ, Huang SJ (2006) Effect of cryogenic treatment on the matrix structure and abrasion resistance of white cast iron subjected to destabilization treatment. Wear 26:1150–1154

Huang JY, Zhu YT, Liao XZ, Beyerlein IJ, Bourke MA, Mitchell TE (2003) Microstructure of cryogenic treated M2 tool steel. Mater Sci Eng A 339:241–244

Gu B, Cong J (1997) Property improvement and microstructure transformation of high-speed steel due to deep cryogenic treatment. Journal of Dalian University of Technology 37(3):285–289

Pellizzari M, Molinari A (2002) Deep cryogenic treatment of cold work tool steel. Proceedings of the 6th International Tooling Conference, Karlstad University, September, pp 657–669

Bryson WE (1999) Cryogenics. Hanser Gardner, Cincinnati, pp 81–107

Stewart HA (2004) Cryogenic treatment of tungsten carbide reduces tool wear when machining medium density fiberboard. For Prod J 54(2):53–56

Gallagher AH, Agosti CD, Roth JT (2005) Effect of cryogenic treatments on tungsten carbide tool life: microstructural analysis. Trans North Am Manuf Res Inst SME 33:153–160

Yugandhar T, Krishnan PK (2002) Cryogenic treatment and its effects on tool steel. Proceedings of 6th International Tooling Conference, Karlstad University, September, pp 671–684

(1985) Understanding tool-steel service life: why the ill-tempered and mistreated take early retirement. Metallurgical Services Staff of Latrobe Steel, Division of Timken Company, Tooling & Production, December

Cohen P, Kamody D (1998) Cryogenics goes deeper. Cutt Tool Eng l50(7):46–50

Bonilla C, O'Meara R, Perry L (2007) Evaluation of the comparative performance of cryogenically treated cutting inserts as a capstone design project. Proceedings of the ASEE Annual Conference and Exposition, pp 9

Arner KA, Agosti CD, Roth JT (2004) Effectiveness of the cryogenic treatment of tungsten carbide inserts on tool wear when in full production operations. American Society of Mechanical Engineers, Mechanical Engineering Division, pp 31–40

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gill, S.S., Singh, H., Singh, R. et al. Cryoprocessing of cutting tool materials—a review. Int J Adv Manuf Technol 48, 175–192 (2010). https://doi.org/10.1007/s00170-009-2263-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2263-9