Abstract

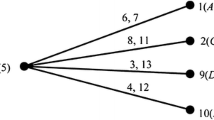

In the sheet metal stamping process for automobiles, the drawing process requires the greatest stamping force, and thus the structure of the drawing dies is the thickest and heaviest among all stamping dies. This study describes how the fuzzy-based Taguchi method can be applied to explore multi-objective optimization in the structural design of drawing dies. Using the lower die of the drawing die for the engine hood’s outer panel as an example, the current study explores four parameters that primarily influence the strength and weight of their structure, namely the rib thickness of the punch open line, the pitch of the structure rib, the thickness of the punch surface, and the thickness of the structure rib. Firstly, CATIA software is used to construct a geometric model of the drawing die, and a structural analysis of the model is performed. Next, within the constraints of allowable stress, allowable deflection and allowable size and pitch of the rib, etc., we apply the Taguchi method to evaluate the allowable characteristics of the two objective functions, namely the deflection and weight of the lower die. Then, through factor effect analysis and analysis of variance, the influences of the design parameters upon the objective functions are determined. Next, a fuzzy logic inference is utilized to obtain the measuring index which results in the optimization of the multiple performance characteristics. Finally, by comparing the results from the maximized design and the results from the original design, it is shown that the deflection of the lower die structure is only increased by 0.0038 mm (8.1%), but its weight can be greatly decreased by 506 kg (12%).

Similar content being viewed by others

References

Lin BT, Kuo CC (2008) Application of an integrated CAD/CAE/CAM system for stamping dies for automobiles. Int J Adv Manuf Technol 35:1000–1013

Sheu JJ, Yang CH (2006) A simplified column model for the automatic design of the stamping die structure. J Mater Process Technol 177:109–113

Wu X, Zhao G, Luan Y, Ma X (2006) Numerical simulation and die structure optimization of an aluminum rectangular hollow pipe extrusion process. Mater Sci and Eng A 435-436:266–274

Pilani R, Narasiman K, Maiti SK, Singh UP, Date PP (2004) A hybrid intelligent system approach for die design in sheet metal forming. Int J Adv Manuf Technol 16:370–375

Pozo DD, Lacalle LNL, Lopez JM, Hernandez A (2008) Prediction of press/die deformation for an accurate manufacturing of drawing dies. Int J Adv Manuf Technol 37:649–656

Lin BT, Chan CK, Wang JC (2008) A knowledge-based parametric design system for drawing dies. Int J Adv Manuf Technol 36:671–680

Lin BT, Chang MR, Huang HL, Liu CY (2009) Computer aided structural design of drawing dies for stamping processes based on functional features. Int J Adv Manuf Technol 42:1140–1152

Vijaya M, Kirshna R, Prabhakar O, Shankar NG (1996) Simultaneous optimization of flame spraying process parameters for high quality molybdenum coating using Taguchi method. Surf Coat Technol 79:276–288

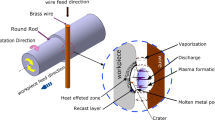

Marafona J, Wykes C (2000) A new method of optimizing material removal rate using EDM with copper-tungsten electrodes. Int J Machine Tools Manuf 40:153–164

Wu HC (2004) Optimising robust design for correlated quality characteristics. Int J Adv Manuf Technol 24:1–8

El-Taweel TA, El-Axir MH (2009) Analysis and optimization of the ball burnishing process through the Taguchi technique. Int J Adv Manuf Technol 41:301–310

Antony J (2001) Simultaneously optimization of multiple quality characteristics in manufacturing process using Taguchi quality loss function. Int J Adv Manuf Technol 17:134–138

Li B, Nye TJ, Metzger DR (2006) Multi-objective optimization of forming parameters for tube hydroforming process based on the Taguchi method. Int J Adv Manuf Technol 28:23–30

Tsao CC (2009) Gray-Taguchi method to optimize the milling parameters of aluminum alloy. Int J Adv Manuf Technol 40:41–48

Zadeh LA (1965) Fuzzy sets. Inform Control 8:338–353

Tarng YS, Yang WH, Juang SC (2000) The use of fuzzy logic in the Taguchi method for the optimization of the submerged arc welding process. Int J Adv Manuf Technol 16:688–694

Tzeng YF, Chen FC (2007) Multi-objective optimisation of high-speed electrical discharge machining process using a Taguchi fuzzy-based approach. Mater Des 28:1159–1168

Palanikumar K, Karunamoorthy L, Karthikeyan R, Latha A (2006) Optimization of machining parameters in Turning GFRP composites using a carbide (K10) tool based on the Taguchi method with fuzzy logics. Met Mater Int 12(6):483–491

Lee HH (2008) Taguchi methods: principles and practices of quality design. Gau-Lih Book Co. Ltd., Taipei

Ross TJ (1995) Fuzzy logic with engineering applications. McGraw-Hill, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, BT., Kuo, CC. Application of the fuzzy-based Taguchi method for the structural design of drawing dies. Int J Adv Manuf Technol 55, 83–93 (2011). https://doi.org/10.1007/s00170-010-3021-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-3021-8