Abstract

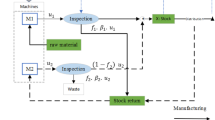

In this paper, a deteriorating production system subject to random machine breakdowns, repair and replacement activities, is investigated. The machine manufactures one type of product, and when a breakdown occurs, either a repair or a replacement action is chosen. The machine is replaced with a new one if the replacement option is selected, and no repair action is considered in such a situation. The decision variables of the control problem are the production rate and the repair/replacement switching policy upon machine failure. The objective of the study is to find the decision variables that minimize the overall cost, including repair, replacement, inventory holding, and backlog costs, over an infinite planning horizon. This paper differs from similar research projects in that it considers the fact that machine repair activities depend on the repair history, and a semi-Markov decision process is used to describe the dynamics of the system. The proposed optimality conditions are developed using the stochastic dynamic programming approach, with a numerical example given to illustrate the utility of the proposed approach, and a sensitivity analysis considered to confirm the structure of the control policy obtained.

Similar content being viewed by others

References

Badia FG, Berrade MD (2009) Optimum maintenance policy of a periodically inspected system under imperfect repair. Advances in Operations Research 2009:13

Boukas E-K, Haurie A (1990) Manufacturing flow control and preventive maintenance: a stochastic control approach. IEEE Trans Autom Control 35(9):1024–1031

Dehayem NFI, Kenné JP, Gharbi A (2009) Hierarchical decision making in production and repair/replacement planning with imperfect repairs under uncertainties. Eur J Oper Res 198(1):173–189

Gharbi A, Kenné JP (2000) Production and preventive maintenance rates control for a manufacturing system: an experimental design approach. Int J Prod Econ 65(3):275–287

Gharbi A, Kenné JP (2003) Optimal production control problem in stochastic multiple-product multiple-machine manufacturing systems. IIE Trans 35:941–952

Hajji A, Gharbi A, Kenné JP (2009) Joint replenishment and manufacturing activities control in two-stage unreliable supply chain. Int J Prod Res 47(12):3231–3251

Hariga MA, Azaiez MN, Daya MB (2006) A discounted integrated inspection–maintenance model for single deteriorating production facility. Int Trans Oper Res 13(4):353–364

Kenne JP, Boukas EK (2003) Hierarchical control of production and maintenance rates in manufacturing systems. J Qual Maint Eng 9(1):66–82

Kijima M, Morimura H, Suzuki Y (1988) Periodical replacement problem without assuming minimal repair. Eur J Oper Res 37(2):194–203

Kushner H, Dupuis PG (1992) Numerical methods for stochastic control problems in continuous time. Springer-verlag, New York

Lai M-T, Chen Y-C (2006) Optimal periodic replacement policy for a two-unit system with failure rate interaction. Int J Adv Manuf Technol 29:367–371

Leung KNF (2006) A note on ‘A bivariate optimal replacement policy for a repairable system’. Eng Optim 38(5):621–625

Love CE, Zhang ZG, Zitron MA, Guo R (1998) An SMDP approach to optimal repair/replacement decisions for systems experiencing imperfect repairs. J Qual Maint Eng 4(2):131–149

Love CE, Zhang ZG, Zitron MA, Guo R (2000) Discrete semi-Markov decision model to determine the optimal repair/replacement policy under general repairs. Eur J Oper Res 125(2):398–409

Makis V, Jardine AKS (1991) Optimal replacement of a system with imperfect repair. Microelectron Reliab 31(2–3):381–388

Makis V, Jardine AKS (1992) Optimal replacement policy for a general model with imperfect repair. J Oper Res Soc 43(2):111–120

Makis V, Jardine AKS (1993) Note on optimal replacement policy under general repair. Eur J Oper Res 69(1):75–82

Mathew S, Kennedy D (2003) A strategy for optimal equipment replacement. Prod Plan Control 14(6):571–577

Mok PY, Porter B (2006) Evolutionary optimisation of hedging points for unreliable manufacturing systems. Int J Adv Manuf Technol 28(1–2):205–214

Ouhbi B, Limnios N (2003) Nonparametric reliability estimation of semi-Markov processes. J Stat Plan Inference 109(1–2):155–165

Pellerin R, Boulet J-F, Gharbi A, Kenne J-P (2007) Développement d’une politique intégrée de contrôle des taux de production et de maintenance corrective avec diagnostic (Development of an integrated control policy of the rates of production and of corrective maintenance with diagnosis). INFOR 45(4):197–207

Rishel R (1975) Control of systems with jump Markov disturbances. IEEE Trans Autom Control AC-20(2):241–244

Sajadi SM, Seyed MM, Sorensen EK (2011) Production control in a failure-prone manufacturing network using discrete event simulation and automated response surface methodology. Int J Adv Manuf Technol 53:35–46

Sethi SP, Zhang Q (1994) Hierarchical decision making in stochastic manufacturing systems. Birkhäuser Verlag Basel, Switzerland, 419

Song D-P (2009) Production and preventive maintenance control in a stochastic manufacturing system. Int J Prod Econ 19(1):101–111

Wang GJ, Zhang YL (2006) Optimal periodic preventive repair and replacement policy assuming geometric process repair. IEEE Trans Reliab 55(1):118–122

Yulan J, Zuhua J, Wenrui H (2008) Multi-objective integrated optimization research on preventive maintenance planning and production scheduling for a single machine. Int J Adv Manuf Technol 39:954–964

Zhou X, Xi L, Jay L (2007) Reliability-centered predictive maintenance scheduling for a continuously monitored system subject to degradation. Reliab Eng Syst Saf 92(4):530–534

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dehayem Nodem, F.I., Kenne, JP. & Gharbi, A. Production planning and repair/replacement switching policy for deteriorating manufacturing systems. Int J Adv Manuf Technol 57, 827–840 (2011). https://doi.org/10.1007/s00170-011-3327-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3327-1