Abstract

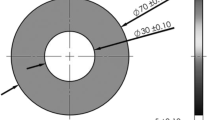

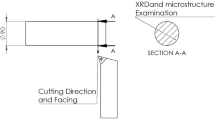

Machinability study on drilling of green austempered ductile iron (ADI) grade was conducted using a TiAlN-coated tungsten carbide drill. The green ADI grade was produced by a novel manufacturing technology known as continuous casting-heat treatment technology to save energy and time in foundry. However, in spite of good combination of strength, toughness and enhanced wear resistance, the microstructural properties of ADI sometimes lead to machinability issues. The effect of cutting parameters on cutting force coefficients, chip morphology, and surface integrity of the drilled surface were discussed. Results showed that the strength properties of novel ADI are comparable to that of ASTM grade 1 ADI, whereas percent elongation is comparable to that of ASTM grade 2 ADI. Results obtained also showed that the combined effect of cutting speed at its higher values and feed rate at its lower values can result in increasing cutting force coefficients and specific cutting energy. At higher cutting speed, hardness values increases at the subsurface layer of the drilled surface due to plastic deformation.

Similar content being viewed by others

References

Eric O, Rajnovic D, Zec S, Sidjanin L, Jovanovic MT (2006) Microstructure and fracture of alloyed austempered ductile iron. Mater Charact 57(4–5):211–217

Seah KHW, Sharma SC (1995) Machinability of alloyed austempered ductile iron. Int J Mach Tool Manufact 35(10):1475–1479

Chang LC (1998) Carbon content of austenite in austempered ductile iron. Scr Mater 39:35–38

Gundlach RB, Janowak JF (1985) Austempered ductile iron combines strength with toughness and ductility. Met Prog 128:19–26.

Klocke DF, Klöpper C, Lung D, Essig C (2007) Fundamental wear mechanisms when machining austempered ductile iron (ADI). CIRP Ann Manuf Technol 56(1):73–76

Putatunda SK, Kesani S, Tackett R, Lawes G (2006) Development of austenite free ADI (austempered ductile cast iron). Mater Sci Eng A 435–436:112–122

Dolinek S (2003) Work-hardening in the drilling of austenitic stainless steels. J Mater Process Technol 133(1–2):63–70

Ballou JR, Joshi SS, Devor RE, Kapoor SG (2007) Burr formation in drilling intersecting holes with machinable austempered ductile iron (MADI). J Manuf Process 9(1):35–46

Namazi E, Pokhrel S (2009) Influence of drilling parameters on carbide containing austempered ductile iron. Chalmers Publication Library: 103552

Meena A, El Mansori M (2011) Study of dry and minimum quantity lubrication drilling of novel austempered ductile iron (ADI) for automotive applications. Wear. doi:10.1016/j.wear.2010.12.022

Meena A, El Mansori M, Ghidossi P, Mkaddem A (2011) Anti-friction coating for drilling of green austempered ductile iron (ADI) grade. AIP Conf Proc 1353:1800–1805

Polishetty A, Littlefair G (2010) Assessment of machining characteristics of austempered ductile iron. Adv Mater Res 97–101:2036–2039

Katuku K, Koursaris A, Sigalas I (2009) Wear, cutting forces and chip characteristics when dry turning ASTM Grade 2 austempered ductile iron with PcBN cutting tools under finishing conditions. J Mater Process Technol 209(5):2412–2420

Zheng L, Zhao L, Xiong W (2009) Tribological properties of TiAlN-coated cermets. Rare Metals 28(1):57–62

Meena A, El Mansori M, Ghidossi P (2010) Machinability of austempered ductile iron (ADI) produced by integrated green technology of continuous casting and heat treatment processes. AIP Conf Proc 1315:1521–1526

Putatunda SK, Gadicherla PK (1999) Influence of austenitizing temperature on fracture toughness of a low manganese austempered ductile iron (ADI) with ferritic as cast structure. Mater Sci Eng A 268(1–2):15–31

Austempered ductile iron (1990) Ductile Iron data for design engineers (Section 4), Rio Tinto Iron and Titanium, Inc.: 1–34

Amran Y, Katsman A, Schaaf P, Bamberger M (2010) Influence of copper addition and temperature on the kinetics of austempering in ductile iron. Metallurg Mater Trans B 1052(41B):1–7

Batra U, Ray S, Prabhakar SR (2004) The influence of nickel and copper on the austempering of ductile iron. J Mater Eng Perform 13(1):64–68

Choi JO, Kim JY, Choi CO, Kim JK, Rohatgi PK (2004) Effect of rare earth element on microstructure formation and mechanical properties of thin wall ductile iron castings. Mater Sci Eng A 383(2):323–333

Bockus S, Dobrovolskis A (2006) Effect of melting techniques on ductile iron castings properties. Metalurgija 45(1):13–16

Jacobs MH, Law TJ, Melford DA, Stowell MJ (1974) Basic process controlling the nucleation of graphite nodules in chill cast iron. Metals Tech 1(11):490–500

Sohi MH, Ahmadabadi MN, Vahdat AB (2004) The role of austempering parameters on the structure and mechanical properties of heavy section ADI. J Mater Process Technol 153–154(1–3):203–208

Davim JP, Sreejith PS, Gomes R, Peixoto C (2006) Experimental studies on drilling of aluminium (AA1050) under dry, minimum quantity of lubricant, and flood-lubricated conditions. Proc IME B J Eng Manufact 220(10):1605–1611

AFNOR NF E 66-520-8 (2000) Domaine de fonctionnement des outils coupants.

Davim JP, Reis P, António CC (2004) Experimental study of drilling glass fiber reinforced plastics (GFRP) manufactured by hand lay-up. Compos Sci Technol 64(2):289–297

Batzer SA, Haan DM, Rao PD, Olson WW, Sutherland JW (1998) Chip morphology and hole surface texture in the drilling of cast aluminum alloys. J Mater Process Technol 79:72–78

Degenhar JA, DeVor RE, Kapoor SG (2005) Generalized groove-type chip breaker effects on drilling for different drill diameters and flute shapes. Int J Mach Tool Manufact 45:1588–1597

Hoshi T, Zhao H (1989) Study of high performance drill geometry. CIRP Ann Manuf Technol 38(1):87–90

Batzer SA, Rao PD, Haan DM, Olson WW, Sutherland JW (1996) An experimental investigation of chip morphology in drilling. S. M. Wu Symposium, volume II, pp 102–107

Olson WW, Batzer SA, Sutherland JW (1998) Modeling of chip dynamics in drilling. CIRP International Workshop on Modeling of Machining Operations 2C/7, pp 1–15

Astakhov VP, Osman MOM, Hayanjneh MT (2001) Re-evaluation of the basic mechanics of orthogonal metal cutting: velocity diagram, virtual work equation and upper-bound theorem. Int J Mach Tool Manufact 41:393–418

Mauvoisin G, Bartier O, El Abdi R, Nayebi A (2003) Influence of material properties on the drilling thrust to hardness ratio. Int J Mach Tool Manufact 43(8):825–832

Dolinsek S, Ekinovic S, Kopac J (2004) A contribution to the understanding of chip formation mechanism in high-speed cutting of hardened steel. J Mater Proc Technol 157–158(special issue):485–490

Subramanian SV, Gekonde HO, Zhu G, Zhang X (2002) Role of microstructural softening events in metal cutting. Mach Sci Technol 6(3):353–364

Şeker U, Hasirci H (2006) Evaluation of machinability of austempered ductile irons in terms of cutting forces and surface quality. J Mater Process Technol 173(3):260–268

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meena, A., El Mansori, M. Drilling performance of green austempered ductile iron (ADI) grade produced by novel manufacturing technology. Int J Adv Manuf Technol 59, 9–19 (2012). https://doi.org/10.1007/s00170-011-3469-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3469-1