Abstract

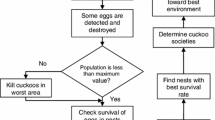

In this research, a new optimization algorithm, called the cuckoo search algorithm (CS) algorithm, is introduced for solving manufacturing optimization problems. This research is the first application of the CS to the optimization of machining parameters in the literature. In order to demonstrate the effectiveness of the CS, a milling optimization problem was solved and the results were compared with those obtained using other well-known optimization techniques like, ant colony algorithm, immune algorithm, hybrid immune algorithm, hybrid particle swarm algorithm, genetic algorithm, feasible direction method, and handbook recommendation. The results demonstrate that the CS is a very effective and robust approach for the optimization of machining optimization problems.

Similar content being viewed by others

References

Taylor FW (1907) On the art of cutting metals. Trans American Soc Mech Engrs 28:31–35

Wang ZG, Rahman M, Wong YS, Sun J (2005) Optimization of multi-pass milling using parallel genetic algorithm parallel genetic simulated annealing. Int J Mach Tools Manuf 45(15):1726–1734

Petropoulos PG (1973) Optimal selection of machining rate variable by geometric programming. Int J Prod Res 11(4):305–314

Shin YC, Joo YS (1992) Optimization of machining conditions with practical constraints. Int J Prod Res 30(12):2907–2919

Agapiou JS (1992) The optimisation of machining operations based on a combined criterion. Part 2: multipass operations. J Eng Ind 114:508–513

Armarego EJA, Simith AJR, Wang J (1994) Computer-aided constrained optimisation analyses strategies for multipass helical tooth milling operation. Ann CIRP 43(1):437–442

Gupta R, Batra JL, Lal JK (1995) Determination of optimal subdivision of depth of cut in multi-pass turning with constraints. Int J Prod Res 33:115–127

Kilic SE, Cogun C, Sen DT (1993) A computer-aided graphical technique for the optimization of machining conditions. Comput Ind 22(3):319–326

Armarego EJA, Smith AJR, Wang J (1993) Constrained optimization strategies CAM software for single-pass peripheral milling. Int J Prod Res 31(9):2139–2160

Rad MT, Bidhendi IM (1997) On the optimization of machining parameters for milling operations. Int J Mach Tools Manuf 37(1):1–16

Wang J (1998) Computer-aided economic optimization of end-milling operations. Int J Prod Econ 54(3):307–320

Wang J, Armarego JA (2001) Computer-aided optimization of multiple constraint single pass face milling operations. Mach Sci Technol 5(1):77–99

Wang J, Kuriyagawa T, Wei XP, Guo DM (2002) Optimization of cutting conditions for single pass turning operations using a deterministic approach. Int J Mach Pass Manufact 42(9):1023–1033

Yildiz AR, Saitou K (2011) Topology synthesis of multi-component structural assemblies in continuum domains. Trans ASME J Mech Des 133(1):011008–011009

Azamathulla HMd, Guven A, Demir YK (2011) Linear genetic programming to scour below submerged pipeline. Ocean Eng 38(8):995–1000

Baskar N, Asokan P, Saravanan R, Prabhaharan G (2005) Optimization of machining parameters for milling operations using non-conventional methods. Int J Adv Manuf Tech 25:1078–1088

Yildiz AR (2009) A new design optimization framework based on immune algorithm and Taguchi’s method, Computers in Industry, 60(8): 613–620

Holland HJ (1975) Adaptation in natural artificial systems, an introductory analysis with application to biology, control artificial intelligence. The University of Michigan Press, Ann Arbor, USA

Kunakote T, Bureerat S (2011) Multi-objective topology optimization using evolutionary algorithms. Eng Optim 43(5):541–557

Yildiz AR (2008) Optimal structural design of vehicle components using topology design and optimization, Materials Testing, 50(4):224–228

Yildiz AR (2012) A new hybrid differential evolution algorithm for the selection of optimal machining parameters in milling operations, Applied Soft Computing, doi:10.1016/j.asoc.2011.12.016

Yildiz AR (2012) Hybrid Taguchi-differential evolution algorithm for optimization of multi-pass turning operations, Applied Soft Computing, doi:10.1016/j.asoc.2012.01.012

Yildiz AR, Ozturk F (2006) Hybrid enhanced genetic algorithm to select optimal machining parameters in turning operation. Proc IME B J Eng Manufact 220(12):2041–2053

Yildiz AR (2009) A novel particle swarm optimization approach for product design and manufacturing. Int J Adv Manuf Technol 40(5–6):617–628

Yildiz AR (2009) Hybrid immune-simulated annealing algorithm for optimal design and manufacturing. Int J Mater Prod Tech 34(3):217–226

Srisompom S, Bureerat S (2008) Geometrical design of plate-fin heat sinks using hybridization of MOEA and RSM. IEEE Trans Compon Packag Tech 31(2):351–360

Yildiz AR, Solanki KN (2012) Multi-objective optimization of vehicle crashworthiness using a new particle swarm based approach, International Journal of Advanced Manufacturing Technology, 59(1-4):367–376

Yildiz AR (2008) Hybrid Taguchi–harmony search algorithm for solving engineering optimization problems. Int J Ind Eng Theory Appl Pract 15(3):286–293

Yildiz AR (2009) A novel hybrid immune algorithm for global optimization in design and manufacturing. Robot Comput-Integrated Manuf 25(2):261–270, A.R

Yildiz AR (2009) An effective hybrid immune-hill climbing optimization approach for solving design and manufacturing optimization problems in industry. J Mater Process Technol 50(4):224–228

Wang ZG, Wong YS, Rahman M (2004) Optimisation of multi-pass milling using genetic algorithm genetic simulated annealing. Int J Adv Manuf Technol 24(9–10):727–732

Machinability Data Center (1980) Machining data handbook, vol. 1, 3rd edition. Machinability Data Center, OH

Yang XS (2008) Nature-inspired metaheuristic algorithms. Luniver Press, UK

Yang XS, Deb S (2009) Cuckoo search via Lévy flights. In: Proceedings of World Congress on Nature and Biologically Inspired Computing. IEEE Publications: USA; 210–214

Yang XS, Deb S (2010) Engineering optimisation by cuckoo search. Int J Math Model Numer Optim 1:330–343

Valian E, Mohanna S, Tavakoli S (2011) Improved cuckoo search algorithm for feed forward neural network training. Int J Artif Intell Appl 2(3):36–43

Walton S, Hassan O, Morgan K, Brown MR (2011) Modified cuckoo search: a new gradient free optimization algorithm. Chaos Solitons Fractals 44:710–718

Kaveh A, Bakhshpoori T (2011) Optimum design of steel frames using cuckoo search algorithm with lévy flights, The Structural Design of Tall and Special Buildings, doi:10.1002/Tal.754

Durgun I, Yildiz AR (2012) Structural design optimization of vehicle components using cuckoo search algorithm, Materials Testing, 54(3):185–188

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yildiz, A.R. Cuckoo search algorithm for the selection of optimal machining parameters in milling operations. Int J Adv Manuf Technol 64, 55–61 (2013). https://doi.org/10.1007/s00170-012-4013-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4013-7