Abstract

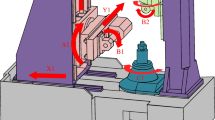

The grinding of elliptical gears on a computer numerical control (CNC) gear grinder with conical wheel is studied according to the mesh theory of elliptical gears. Two machining methods form the machine structure and movement, namely a mobile grinding wheel type and a fixed grinding wheel type. Mathematical models of the movement relation for the elliptical gear grinding process are built up. Since the teeth of the elliptical gears are different from each other, their generating length is also different. Based on the analysis of generating and indexing movement, a universal generating length formula of each tooth is proposed. Basic machining parameters of each tooth, for these two types of machines, are computed using a practical example. The dynamic simulation of generating track is given. The research results show that the grinding of elliptical gears with a CNC conical wheel gear grinder is feasible.

Similar content being viewed by others

References

Xutang Wu, Guihai Wang (1997) Elliptical gears and non-uniformity velocity ratio transmission. Mechanical Industry Publishing House, Beijing, P. R. China

Horiuchi Y (1989) On the gear theory suggested by Leibnits (2nd Report, The analysis of noncircular gears). Bulletin of the Japan Society of Precision Engineering 23(2):146–151

Chang SL, Tsay CB, Wu LI (1996) Mathematical model and undercutting analysis of elliptical gears generated by rack cutter. Mechanism and Machine Theory 31(7):879–890

Chang SL, Tsay CB (1998) Computerized tooth profile generation and undercut analysis of noncircular gears manufactured with shaper cutters. Transactions of the ASME, Journal of Mechanical Design 120(1):92–99

Tan W, Chibing Hu, Xian W (2001) Concise mathematical model for hobbing non-circular gear and its graphic simulation. Chinese Journal of Mechanical Engineering 37(5):26–29

Bair BW (2004) Computer aided design of elliptical gears with circular-arc teeth. Mechanism and Machine Theory 39(2):153–168

Li JianGang, XuTang Wu, Mao ShiMin (2007) Numerical computing method of noncircular gear tooth profiles. The International Journal of Advanced Manufacturing Technology 33:1098–1105

Xi’an Jiaotong University (1977) Gear grinding theory. Mechanical Industry Publishing House, Beijing, P. R. China

Tong SH, Yang CH (1998) Generation of identical noncircular pitch curves. Transactions of the ASME, Journal of Mechanical Design 120(2):337–341

Bair BW (2002) Computer aided design of elliptical gears. Transactions of the ASME, Journal of Mechanical Design 124(6):787–793

Litvin FL (1994) Gear geometry and applied theory. Prentice Hall, Englewood Cliffs, New Jersey

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Gong, J. & Wu, X. Investigation on the grinding of elliptical gears with CNC conical wheel gear grinder. Int J Adv Manuf Technol 64, 349–356 (2013). https://doi.org/10.1007/s00170-012-4028-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4028-0