Abstract

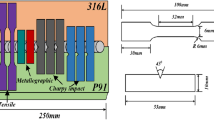

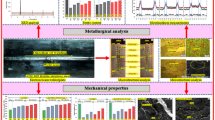

In this study, AISI 316 L austenitic stainless steel and AH36 low-alloy ship building steel pair were joined with flux-cored arc welding method by using E309LT1-1/4 filler metal under four different shielding gas compositions containing CO2 at different ratios. Microstructure, impact toughness of welded materials, and their microhardness distribution throughout joining were determined. In macro- and microstructure examinations, stereo optical microscope, scanning electron microscope (SEM), SEM/energy dispersive spectroscopy, and SEM/mapping analysis techniques were used. After notched impact toughness, fracture surfaces were examined using the scanning electron microscope. This study investigated effects of shielding gas composition on microstructure, impact toughness, and microhardness distribution of transition zone between AH36 steel and weld metal of joined material. It is observed that based on an increase in amount of CO2 in shielding gas, impact toughness values of the weldment decreased. Microhardness values change throughout weld metal depended on shielding gas composition. Moreover, an increase in amount of CO2 within shielding gas decreased δ-ferrite amount in weld metal. The increase in amount of CO2 within shielding gas leads to expanded transition zone in interface between AH36 and weld metal and also affects notched impact toughness values negatively due to the inclusion amounts occurring in weld metal and hence caused it to decrease.

Similar content being viewed by others

References

Nowacki J, Urbanski M, Zaja P (2009) FCAW welding of duplex steel in construction of chemical cargo carriers. Weld Int 23(7):34–42

Sireesha M, Albert SK, Shankar V, Sundaresan S (2000) A comparative evaluation of welding consumables for dissimilar welds between 316LN austenitic stainless steel and Alloy 800. J Nucl Mater 279(1):65–76

Sireesha M, Shankar V, Albert SK, Sundaresan S (2000) Microstructural features of dissimilar welds between 316LN austenitic stainless steel and alloy 800. Mater Sci Eng A 292:74–82

Maruyama T (2003) Arc welding technology for dissimilar joints. Weld Int 17(4):276–281

Huang ML, Wang L (1998) Carbon migration in 5Cr–0.5Mo/21Cr–12Ni dissimilar metal welds. Metall Mater Trans A 29(12):3037–3046

Jang C, Lee J, Kim JS, Jin TE (2008) Mechanical property variation within Inconel 82/182 dissimilar metal weld between low alloy steel and 316 stainless steel. Int J Pres Ves Pip 85:635–646

Wang S, Ma Q, Li Y (2011) Characterization of microstructure, mechanical properties and corrosion resistance of dissimilar welded joint between 2205 duplex stainless steel and 16MnR. Mater Des 32:831–837

Wang SG, Dong GP, Ma QH (2009) Welding of duplex stainless steel composite plate: influence on microstructural development. Mater Manuf Process 24:1383–1388

Kaçar R, Acarer M (2003) Microstructure–property relationship in explosively welded duplex stainless steel–steel. Mater Sci Eng A 363:290–296

Lippold JC, Kotecki DJ (2005) Welding metallurgy and weldability of stainless steels. Wiley, NJ

Lundin CD (1982) Metal welds-transition joints literature-review. Weld J 61:58s–63s

Pala Srinivasan B, Muthupandi V, Dietzel W, Sivan V (2006) An assessment of impact strength and corrosion behaviour of shielded metal arc welded dissimilar weldments between UNS 31803 and IS 2062 steels. Mater Des 27:182–191

Bala Srinivasan P, Satish Kumar MP (2009) Microstructural and electrochemical characterization of a thin-section dissimilar stainless steel weld joint. Mater Chem Phys 115:179–184

You YY, Shiue RK, Shiue RH, Chen C (2001) The study of carbon migration in dissimilar welding of the modified 9Cr-1Mo steel. J Mater Sci Lett 20:1429–1432

Vigraman T, Narayanasamy R, Ravindran D (2012) Microstructure and mechanical property evaluation of diffusion-bonded joints made between SAE 2205 steel and AISI 1035 steel. Mater Des 35:156–169

Çelik A, Alsaran A (1999) Mechanical and structural properties of similar and dissimilar steel joints. Mater Charact 43:311–318

Rowe MD, Nelson TW, Lippold JC (1999) hydrogen-induced cracking along the fusion boundary of dissimilar metal welds. Weld Res Suppl:31s-37s

Arivazhagan N, Singh S, Prakash S, Reddy GM (2011) Investigation on AISI 304 austenitic stainless steel to AISI 4140 low alloy steel dissimilar joints by gas tungsten arc, electron beam and friction welding. Mater Des 32:3036–3050

Kurt B, Çalik A (2009) Interface structure of diffusion bonded duplex stainless steel and medium carbon steel couple. Mater Charact 60:1035–1040

Satyanarayana VV, Madhusudhan Reddy G, Mohandas T (2005) Dissimilar metal friction welding of austenitic–ferritic stainless steels. J Mater Process Technol 160:128–137

Lathabai S, Stout RD (1985) Shielding gas and heat input effects on flux-cored weld metal properties. Weld J 64(11):303s–313s

Mukhopadhyay S, Pal TK (2006) Effect of shielding gas mixture on gas metal arc welding of HSLA steel using solid and flux-cored wires. Int J Adv Manuf Technol 29:262–268

Gençkan D, Saraçoğlu E (2009) Technology of flux cored welding. Mühendis ve Makine, 50:599, pp. 75-79 (In Turkish)

Gençkan HD, Keskinkılıç S, Saraçoğlu E, Koçak M (October 2011) The comparison of microstructure and mechanical properties of flux-cored wires (FCAW), international congress on advances in welding science and technology for construction, energy and transportation systems (AWST-2011), pp. 19-24, 24-25, Antalya

Lyttle KA. Shielding gases. In: Materials handbook of ASM 6:64

Liao MT, Chen PY (1998) the effect of shielding-gas compositions on the microstructure and mechanical properties of stainless steel weldments. Mater Chem Phys 55:145–151

Liao MT, Chen PY (1998) The influence of shielding gas on notch toughness of stainless steel weld metals. Mater Manuf Process 13(4):565–573

Sathiya P, Aravından S, Soundararajan R, Noorul Haq A (2009) Effect of shielding gases on mechanical and metallurgical properties of duplex stainless-steel welds. J Mater Sci 44(1):114–121

Yılmaz R, Barlas Z (2005) The effect of shielding-gas compositions on the microstructure and mechanical properties of austenitic stainless steel weldments, Pamukkale University. J Eng Sci 11:3, 391–400 (In Turkish)

Yılmaz R, Abuç S (16–18 October 2008) The effect of shielding gases on the toughness of stainless steels weldments. 14th International Metallurgy & Materials Congress, pp. 105-112, Istanbul. (In Turkish)

Yılmaz R, Tümer M (11–17 July 2010) The effect of shielding gases on the microstructure and toughness of stainless steels weldments by FCAW. 63rd Annual Assembly& International Conference of the International Institute of Welding, pp. 847-852, Istanbul

Arivazhagan B, Sundaresan S, Kamaraj M (2009) A study on influence of shielding gas composition on toughness of flux-cored arc weld of modified 9Cr–1Mo (P91) steel. J Mater Process Technol 209:5245–5253

Tulbentci K, Kaluç E (1997) MIG/MAG welding. Arctech Publication, Istanbul, pp 35–41

Ebrahimnia M, Goodarzi M, Nouri M, Sheikhi M (2009) Study of the effect of shielding gas composition on the mechanical weld properties of steel ST 37-2 in gas metal arc welding. Mater Des 30:3891–3895

Tusek J, Suban M (2000) Experimental research of the effect of hydrogen in argon as a shielding gas in arc welding of high-alloy stainless steel. Int J Hydrogen Energ 25:369–376

Tusek J, Suban M (2001) Dependence of melting rate in MIG/MAG welding on the type of shielding gas used. J Mater Process Technol 119:185–192

(2012) http://www.matweb.com

Bala Srinivasan P, Muthupandi V, Dietzel W, Sivan V (2006) Microstructure and corrosion behavior of shielded metal arc-welded dissimilar joints comprising duplex stainless steel and low alloy steel. J Mater Eg Perform 15:758–764

Nelson TW, Lippold JC, Mills MJ (2000) Nature and evolution of the fusion boundary in ferritic-austenitic dissimilar metal welds-part 2: on-cooling transformations. Weld Res Suppl:267s-277s

Cleiton CS, Hélio CDM, Hosiberto BDS, Jesualdo PF (2009) Microstructure, hardness and petroleum corrosion evaluation of 316 L/AWS E309MoL-16 weld metal. Mater Charact 60:346–352

Zhu ML, Xuan FZ (2010) Effects of temperature on tensile and impact behavior of dissimilar welds of rotor steels. Mater Des 31:3346–3352

Kacar R, Baylan O (2004) An investigation of microstructure/property relationships in dissimilar welds between martensitic and austenitic stainless steels. Mater Des 25:317–329

Lee DJ, Byun JC, Sung JH, Lee HW (2009) The dependence of crack properties on the Cr/Ni equivalent ratio in AISI 304 L austenitic stainless steel weld metals. Mater Sci Eng A 513–514:154–159

Silva CC, Hélio C, Santana MHB, Farias JP (2009) Microstructure, hardness and petroleum corrosion evaluation of 316 L/AWS E309MoL-16 weld metal. Mater Charact 60:346–352

Mukherjee M, Pal TK (2012) Influence of heat input on martensite formation and impact property of ferritic-austenitic dissimilar weld metals. J Mater Sci Technol 28:343–352

Elmer JW, Allen SM, Eagar TW (1989) Microstructural development during solidification in stainless steel alloys, Metall. Trans A Phys Metall Mater Sci 20(10):2117–2131

(1994) Welding metallurgy of stainless steels. Abington Welding Training Module, Cambridge, pp. 1-45

Dieter GE (1988) Mechanical metallurgy. McGraw-Hill, London, p 476

Park BG, Crosky AG, Hellier AK (2008) Fracture toughness of microsphere Al2O3–Al particulate metal matrix composites. Compos B Eng 39:1270–1279

Grong O, Christensen N (1983) Factors controlling MIG weld metal chemistry. Scand J Metall 12:155–165

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yılmaz, R., Tümer, M. Microstructural studies and impact toughness of dissimilar weldments between AISI 316 L and AH36 steels by FCAW. Int J Adv Manuf Technol 67, 1433–1447 (2013). https://doi.org/10.1007/s00170-012-4579-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4579-0