Abstract

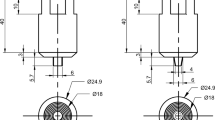

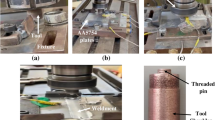

This paper presents a multi-response optimization process for dissimilar friction stir welding of AA6082/AA5754 aluminum alloys. An L9 orthogonal array was constituted for the experiments. Three welding parameters—tool shoulder diameter-to-pin diameter (D/d) ratio, tool rotational speed (TRS), and welding speed (WS)—were associated with tensile strength and elongation. An optimization process was started to determine the signal-to-noise (S/N) ratio. Grey relational analyses were performed utilizing the S/N ratio. According to the results of a series of analyses, the optimal welding condition was determined as 4 for D/d, 1,000 rpm for TRS, and 100 mm/min for WS. The analysis of variance results showed that all the welding parameters are statistically significant at 95 % confidence level. Additionally, the joint efficiency of welding fabricated at the optimal condition was compared for both AA6082 and AA5754. This revealed that the joint efficiency is 66 % for AA6082 and 92 % for AA5754.

Similar content being viewed by others

References

Taban E, Kaluc E (2006) Microstructural and mechanical properties of double-sided MIG, TIG and friction stir welded 5083-H321 aluminum alloy. Kovove Mater 44:25–33

Rajakumar S, Muralidharan C, Balasubramanian V (2010) Optimization of the friction-stir-welding process and tool parameters to attain a maximum tensile strength of AA7075–T6 aluminum alloy. Proc IME B J Eng Manufact 224(8):1175–1191

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50:1–78

Sharma C, Dwivedi DK, Kumar P (2012) Effect of welding parameters on microstructure and mechanical properties of friction stir welded joints of AA7039 aluminum alloy. Mater Des 36:379–390

Abbass MK, Ameen HA, Hassan KS (2011) Effect of heat treatment on corrosion resistance of friction stir welded AA 2024 aluminum alloy. Am J Sci Ind Res 2(2):297–306

Lakshminarayanan AK, Balasubramanian V, Elangovan K (2009) Effect of welding processes on tensile properties of AA6061 aluminum alloy joints. Int J Adv Manuf Technol 40:286–296

Sayer S, Yeni C, Ertugrul O (2011) Comparison of mechanical and microstructural behaviors of tungsten inert gas welded and friction stir welded dissimilar aluminum alloys AA 2014 and AA 5083. Kovove Mater 49:155–162

Fratini L, Buffa G, Filice L, Gagliardi F (2006) Friction stir welding of AA6082-T6 T-joints: process engineering and performance measurement. Proc IME B J Eng Manuf 220(5):669–676

Scialpi A, Filippis LAC, Cavaliere P (2007) Influence of shoulder geometry on microstructure and mechanical properties of friction stir welded 6082 aluminum alloy. Mater Des 28:1124–1129

Sakthivel T, Sengar GS, Mukhopadhyay J (2009) Effect of welding speed on microstructure and mechanical properties of friction stir welded aluminum. Int J Adv Manuf Technol 43:468–473

Zhang Z, Liu YL, Chen JT (2009) Effect of shoulder size on the temperature rise and the material deformation in friction stir welding. Int J Adv Manuf Technol 45:889–895

Yeni C, Sayer S, Pakdil M (2009) Comparison of mechanical and microstructural behavior of TIG, MIG and friction stir welded 7075 aluminum alloy. Kovove Mater 47:341–347

Kim WK, Goo BC, Won S-t (2010) Optimal design of friction stir welding process to improve tensile force of the joint of A6005 extrusion. Mater Manuf Process 25:637–643

Colligan K (1999) Material flow behavior during friction stir welding of aluminum. Am Weld Soc Weld Res Counc Weld J 78:229–237

Kumar K, Kailas SV, Srivatsan TS (2008) Influence of tool geometry in friction stir welding. Mater Manuf Process 23:188–194

Aval HJ, Serajzadeh S, Kokabi AH (2011) Thermo-mechanical and microstructural issues in dissimilar friction stir welding of AA5086–AA6061. J Mater Sci 46:3258–3268

Alvarez P, Arruti E, Aldanondo E, Alberto E (2012) Understanding material flow in FSW and its implications. Proceedings of the second international conference FSWP’2012, ISBN: 978-2-911256-72-1, France

Palanivel R, Mathews PK, Murugan N, Dinaharan I (2012) Effect of tool rotational speed and pin profile on microstructure and tensile strength of dissimilar friction stir welded AA5083-H111 and AA6351-T6 aluminum alloys. Mater Des 40:7–16

Leitao C, Louro R, Rodrigues DM (2012) Analysis of high temperature plastic behavior and its relation with weldability in friction stir welding for aluminum alloys AA5083-H111 and AA6082-T6. Mater Des 37:402–409

Panda S, Mishra D, Biswal BB (2011) Determination of optimum parameters with multi performance characteristics in laser drilling—a grey relational analysis approach. Int J Adv Manuf Technol 54:957–967

Aydin H, Bayram A, Esme U, Kazancoglu Y, Guven O (2010) Application of grey relation analysis (GRA) and Taguchi method for the parametric optimization of friction stir welding (FSW) process. Mater Technol 44(4):205–211

Chien CH, Lin WB, Chen T (2011) Optimal FSW process parameters for aluminum alloys AA5083. J Chin Inst Eng 34(1):99–105

Suresha CN, Rajaprakash BM, Upadhya S (2011) A study of the effect of tool pin profile on tensile strength of welded joints produced using friction stir welding process. Mater Manuf Process 26:1111–1116

Rezgui MA, Ayadi M, Cherouat A, Hamrouni K, Zghal A, Bejaoui S (2010) Application of Taguchi approach to optimize friction stir welding parameters of polyethylene. EPJ Web Conf 6:07003

Vijayan S, Raju R, Rao SRK (2010) Multiobjective optimization of friction stir welding process parameters on aluminum alloy AA 5083 using Taguchi-based grey relation analysis. Mater Manuf Process 25:1206–1212

Koilraj M, Sundareswaran V, Vijayan S, Rao SRK (2012) Friction stir welding of dissimilar aluminum alloys AA2219 to AA5083—optimization of process parameters using Taguchi technique. Mater Des 42:1–7

Meena VK, Azad MS (2012) Grey relational analysis of micro EDM machining of Ti–6Al–4V alloy. Mater Manuf Process 27:973–977

Lin CL (2004) Use of Taguchi method and grey relational analysis to optimize turning operations with multiple performance characteristics. Int J Adv Manuf Technol 19(2):209–220

Palanikumar K, Latha B, Senthilkumar VS, Davim P (2012). Analysis on drilling of glass fiber-reinforced polymer (GFRP) composites using grey relational analysis. Mater Manuf Process 27:297–305

Haq AN, Marimuthu P, Jeyapaul R (2008) Multi response optimization of machining parameters of drilling Al/SiC metal matrix composite using grey relational analysis in the Taguchi method. Int J Adv Manuf Technol 37:250–255

Pawade RS, Joshi SS (2011) Multi-objective optimization of surface roughness and cutting forces in high-speed turning of Inconel 718 using Taguchi grey relational analysis (TGRA). Int J Adv Manuf Technol 56:47–62

Asokan P, Kumar RR, Jeyapaul R, Santhi M (2008) Development of multi-objective optimization models for electrochemical machining process. Int J Adv Manuf Technol 39:55–63

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kasman, Ş. Multi-response optimization using the Taguchi-based grey relational analysis: a case study for dissimilar friction stir butt welding of AA6082-T6/AA5754-H111. Int J Adv Manuf Technol 68, 795–804 (2013). https://doi.org/10.1007/s00170-012-4720-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4720-0