Abstract

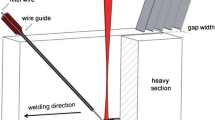

In laser welding, typical welding penetration depths are in the order of 1–2 mm/kW laser power. The multipass laser welding technique, based on the narrow-gap approach, is an emerging welding technology that can be applied to thick-section welds by using relatively low laser power, but the process is more complicated since it is necessary to introduce filler wire to narrow-gap weld configurations. The aim of this work was to understand significant process parameters and their interactions in order to control the weld quality in ultra-narrow-gap (1.5 mm gap width) laser welding of AISI grade 316L stainless steel. A 1-kW IPG single-mode fiber laser was used for welding plates that were 5 to 20 mm in thickness using the multiple-pass narrow-gap approach. Design of experiments and statistical modelling techniques were employed to understand and optimise the processing parameters. The effects of laser power, wire feed rate, and welding speed on the weld homogeneity, integrity, bead shape, gap bridgability and surface oxidation were studied. The results were evaluated under different optimising constraints. The results show that the models developed in this work can effectively predict the responses within the factors domain.

Similar content being viewed by others

References

Reisgen U, Schleser M, Mokrov O, Ahmed E (2012) Optimization of laser welding of DP/TRIP steel sheets using statistical approach. Opt Laser Technol 44(1):255–262

Reisgen U, Schleser M, Mokrov O, Ahmed E (2012) Statistical modeling of laser welding of DP/TRIP steel sheets. Opt Laser Technol 44(1):92–101

Zhang X, Ashida E, Tarasawa S Properties of welded joint for narrow gap laser welding of austenitic stainless steels. In: ICALEO, USA, 2010. pp 632–637

Starling C, Marques PV, Modenesi PJ (1995) Statistical modelling of narrow-gap GTA welding with magnetic arc oscillation. J Mater Process Technol 51(1):37–49

Xudong Zhang EA (2010) welding of thick stainless steel plates up to 50 mm with high brightness lasers. Paper presented at the International Congress on Applications of lasers and Electro-Optics, USA,

Sun Z, Salminen A (1997) Current status of laser welding with wire feed. Mater Manuf Process 12(5):759–777

Sun Z, Kuo M (1999) Bridging the joint gap with wire feed laser welding. J Mater Process Technol 87(1–3):213–222

Manonmani K, Murugan N, Buvanasekaran G (2007) Effects of process parameters on the bead geometry of laser beam butt welded stainless steel sheets. Int J Adv Manuf Technol 32(11):1125–1133

Benyounis K, Olabi A, Hashmi M (2005) Effect of laser welding parameters on the heat input and weld-bead profile. J Mater Process Technol 164:978–985

Torkamany M, Hamedi M, Malek F, Sabbaghzadeh J (2006) The effect of process parameters on keyhole welding with a 400 W Nd:YAG pulsed laser. J Phys D: Appl Phys 39:4563–4567

Salminen AS Effects of filler wire feed on the efficiency of laser welding. In: Isamu M, Kojiro FK, Koji S, Reinhart P, Henry H (eds), 2003. vol 1. SPIE, pp 263-268

Salminen A (2010) The filler wire-laser beam interaction during laser welding with low alloyed steel filler wire. Mechanika 4(84):67–74

Benyounis K, Olabi A (2008) Optimization of different welding processes using statistical and numerical approaches—a reference guide. Adv Eng Softw 39(6):483–496

Box G, Wilson K (1951) On the experimental attainment of optimum conditions. J R Stat Soc B13:1–45

Leigh S, Sezer K, Li L, Grafton-Reed C, Cuttell M (2009) Statistical analysis of recast formation in laser drilled acute blind holes in CMSX-4 nickel superalloy. Int J Adv Manuf Technol 43(11):1094–1105

Murugan N, Parmar RS (1994) Effects of MIG process parameters on the geometry of the bead in the automatic surfacing of stainless steel. J Mater Process Technol 41(4):381–398

Anawa E, Olabi A (2008) Using Taguchi method to optimize welding pool of dissimilar laser-welded components. Opt Laser Technol 40(2):379–388

Palani PK, Murugan N (2007) Optimization of weld bead geometry for stainless steel claddings deposited by FCAW. J Mater Process Technol 190(1–3):291–299

Salminen A (2010) The filler wire-laser beam interaction during laser welding with low alloyed steel filler wire. J Mechanika 84:67–74

ASSOCIATION BSS (2007) http://www.bssa.org.uk/topics.php?article=140.

Ruggiero A, Tricarico L, Olabi A, Benyounis K (2011) Weld-bead profile and costs optimisation of the CO < sub > 2</sub > dissimilar laser welding process of low carbon steel and austenitic steel AISI316. Opt Laser Technol 43(1):82–90

Jokinen T, Kujanpää V (2003) High power Nd:YAG laser welding in manufacturing of vacuum vessel of fusion reactor. Fusion Eng Design 69(1–4):349–353

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Elmesalamy, A.S., Li, L., Francis, J.A. et al. Understanding the process parameter interactions in multiple-pass ultra-narrow-gap laser welding of thick-section stainless steels. Int J Adv Manuf Technol 68, 1–17 (2013). https://doi.org/10.1007/s00170-013-4739-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-4739-x