Abstract

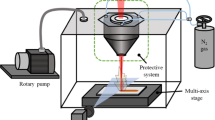

Unlike the normal vacuum chamber that a workpiece is put inside, a new vacuum chamber was designed to put on the welding zone of a workpiece, which has no size limit with this chamber, so that a large and thick plate could be welded with laser under low pressure. In this new vacuum chamber, a local subatmospheric pressure on the welding zone was achieved with side draught by a vacuum pump. A series of spot welding experiments were performed with fiber laser under subatmospheric pressure, normal atmospheric pressure with and without shielding gas side-blowing, respectively. The feature of weld surfaces and cross-section profiles for above different conditions were compared. A high-speed camera was applied to observe the behavior of plasma plume. The results indicated that the deeper welding penetration and narrower weld bead width could be obtained under subatmospheric pressure. The characteristics of spot weld bead under local subatmospheric pressure were quite different from the one under normal atmospheric pressure with shielding gas side-blowing method. The plasma plume was suppressed more effectively by local subatmospheric pressure than that by shielding gas side-blowing. Additional experiments of continuous laser welding under local subatmospheric pressure were tried and sound welds could be obtained.

Similar content being viewed by others

References

Hamidinejad SM, Hasanniya MH, Salari N, Valizadeh E (2013) CO2 laser welding of interstitial free galvanized steel sheets used in tailor welded blanks. Int J Adv Manuf Technol 64:195–206

Elmesalamy AS, Li L, Francis JA, Sezer HK (2013) Understanding the process parameter interactions in multiple-pass ultra-narrow-gap laser welding of thick-section stainless steels. Int J Adv Manuf Technol 68:1–17

Chen HC, Aj P, Li L (2011) Fibre laser welding of dissimilar alloys of Ti-6Al-4 V and Inconel 718 for aerospace applications. Int J Adv Manuf Technol 52:977–987

Caiazzo F, Alfieri V, Sergi V, Schipani A, Cinque S (2013) Dissimilar autogenous disk-laser welding of Haynes 188 and Inconel 718 superalloys for aerospace applications. Int J Adv Manuf Technol 68:1809–1820

Havrilla D, Ryba T, Holzer M (2012) High power disk lasers—advances & applications. In: Proceedings of SPIE, pp.65-70

Vollertsen F, Thomy C (2005) Welding with fiber lasers from 200 to 17000W. In: Proceedings of ICALEO, pp.254-263

Verwaerde A, Fabbro R, Deshors G (1995) Experimental study of continuous CO2 laser welding at subatmospheric pressures. J Appl Phys 78:2981–2984

Arata Y, Abe N, Oda T, Tsujii N (1985) Fundamental phenomena during vacuum laser welding. In: Proceedings of ICSLEO Materials Processing Symp, pp. 1–7

Katayama S, Kobayashi Y, Mizutani M, Matsunawa A (2001) Effect of vacuum on penetration and defects in laser welding. J Laser Appl 13:187–192

Katayama S, Yohei A, Mizutani M, Kawahito Y (2001) Development of deep penetration welding technology with high brightness laser under vacuum. Phys Procedia 12:75–80

Katayama S, Kawahito Y, Mizutani M (2012) Latest progress in performance and understanding of laser welding. Phys Procedia 39:8–16

Mai T. A, Lim G. C, Tay G.H, KOH E. W (2002) Laser vacuum welding of aluminium, kovar and Ni-Fe alloys for hermetic encapsulation of electronic components. In: Proceedings of ICSLEO, pp. 24–30.

Reisgen U, Olschok S, Longerich S (2010) Laser beam welding in vacuum—a process variation in comparison with electron beam welding. In: Proceedings of ICALEO 2010, pp. 638–647

Zhao H, Niu W, Zhang B, Lei Y, Kodama M, Ishide T (2011) Modelling of keyhole dynamics and porosity formation considering the adaptive keyhole shape and three-phase coupling during deep-penetration laser welding. J Phys D Appl Phys 44:360–368

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luo, Y., Tang, X. & Lu, F. Experimental study on deep penetrated laser welding under local subatmospheric pressure. Int J Adv Manuf Technol 73, 699–706 (2014). https://doi.org/10.1007/s00170-014-5870-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5870-z