Abstract

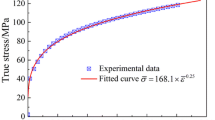

Bending of an aluminum alloy thin-walled tube with larger diameter-to-thickness ratio is more difficult than that of a mild steel or stainless steel tube due to its low elastic modulus and yield strength. To solve this problem, experiments were conducted on hydro-bending of bi-layered tubes, which consist of an outer mild steel tube and an inner aluminum alloy thin-walled tube. The wrinkling behavior, springback, cross-sectional non-circularity, and wall thickness variation of the inner aluminum alloy tube were analyzed. It has been shown that the internal pressure plays a prominent role in preventing the wrinkling due to an additional axial tensile stress being introduced to the inner tube through welding the inner tube ends onto the surface of the outer tube. By increasing the internal pressure to a critical value, it is helpful to reduce the magnitude of compressive stress at the inner side of bent tubes, so the onset of winking is prevented. The springback and the cross-sectional non-circularity become smaller, while the thinning rate gets bigger with pressure increasing. Finally, a sound aluminum alloy thin-walled tube with diameter-to-thickness ratio of 63 and relative bending radius of 2.2 was successfully formed under the internal pressure of 25 MPa.

Similar content being viewed by others

References

Jeswiet J, Geiger M, Engel U, Kleiner M, Schikorra M, Duflou J, Neugebauer R, Bariani P, Bruschi S (2008) Metal forming progress since 2000. CIRP J Manuf Sci Technol 1(1):2–17

Yang H, Gu RJ, Zhan M, Li H (2006) Effect of frictions on cross section quality of thin-walled tube NC bending. Trans Nonferrous Met Soc China 16(4):878–886

Strano M (2005) Automatic tooling design for rotary draw bending of tubes. Int J Adv Manuf Technol 26:733–740

Li H, Yang H, Xu J, Liu H, Wang D, Li GJ (2013) Knowledge-based substep deterministic optimization of large diameter thin-walled Al-alloy tube bending. Int J Adv Manuf Technol 68:1989–2004

Kami A, Dariani BM (2011) Prediction of wrinkling in thin-walled tube push-bending process using artificial neural network and finite element method. Proc IMechE Part B: J Eng Manuf 225(10):1801–1812

Miller JE, Kyriakides S, Bastard AH (2001) On bend-stretch forming of aluminum extruded tubes—I: experiments. Int J Mech Sci 43(5):1283–1317

Li H, Yang H, Zhang ZY, Wang ZK (2013) ‘Size effect’ related bending formability of thin-walled aluminum alloy tube. Chin J Aeronaut 26(1):230–241

Wang J, Agarwal R (2006) Tube bending under axial force and internal pressure. J Manuf Sci Eng 128(2):598–605

Lovric M (2010) Press-bending of thin-walled tubes. In: Liewald M (ed) Proceedings of the 4th international conference on hydroforming (MAT-INFO, Frankfurt). Fellbach, Germany, pp 365–386

Teng BG, Hu L, Yuan SJ (2013) Deformation behavior of thin-walled tubes bending with internal pressure. Rev Adv Mater Sci 33(5):436–441

Wang XS, Song P, Zhao ZY, Yuan SJ (2011) Influence of tube ends constraint on hydro-bending of thin-walled aluminum tube. Trans Nonferrous Met Soc China 21:s440–s444

Yuan SJ, Hu L, Liu G, Teng BG (2012) A new hydroforming process of ultra-thin elbow tube. In: Kusiak J, Majta J, Szeliga D (eds) Proceedings of the 14th international conference on metal forming. Krakow, Poland, pp 631–634

Yuan SJ, He ZB, Liu G (2012) New developments of hydroforming in China. Mater Trans 53(5):787–795

Hu L, Teng BG, Yuan SJ (2012) Effect of internal pressure on hydro bending of bi-layered tube. Proc IMechE Part B: J Eng Manuf 226(10):1717–1726

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, W., Teng, B. & Yuan, S. Deformation analysis of hydro-bending of bi-layered metal tubes. Int J Adv Manuf Technol 79, 211–219 (2015). https://doi.org/10.1007/s00170-015-6830-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6830-y