Abstract

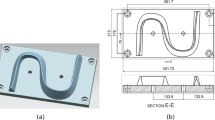

The manufacturing test part applications are essential for representations of machines’ capabilities. Commonly used NAS979 has been known to insufficiently evaluate the combination motions of rotary axes. Thus, a new test part, S part, has been presented to satisfy the increasing demand of a five-axis machine. In this paper, the model of S part is described in detail, which presents more characteristics in three-dimensional surface contours. According to the kinematics analysis, the speed of each axis and feed rate falls down and rises up on several positions. Each axis reverses the motion during the machining. Therefore, the S part makes high requirement on machine’s dynamic response.

Similar content being viewed by others

References

Schmitz TL, Ziegert JC, Zapata R (2006) Part accuracy in high-speed machining: preliminary results. Proceeding of MESC, Ypsilanti, USA, MSEC:851–858

Andolfatto LL, Mayer JRR (2011) Evaluation of servo, geometric and dynamic error sources on five-axis high-speed machine tool. Int J Mach Tools Manuf 51:787–796

ISO 230–1 (1996) Test code for machine tools—part 1: geometric accuracy of machines operating under no-load or finishing conditions

Ibaraki S, Oyama C, Otsubo H (2011) Construction of an error map of rotary axes on a five-axis machining center by static R-test. Int J Mach Tools Manuf 51:190–200

Mehrdad G, Mayer JRR (2014) Validation of volumetric error compensation for a five-axis machine using surface mismatch producing tests and on-machine touch probing. 87:89-95

NAS979 (1969) Uniform cutting test-NAS series, metal cutting equipment. NAS, USA

ISO 10791-7 (1988) Test conditions for machining centres—part 7: accuracy of a finished test piece

Burak S, Yusuf A, Elizabeth C (2009) Modeling and control of contouring errors for five-axis machine tools—part I: modeling. J Manuf Sci Eng 131:1–8

Zhenya H, Jianzhong F, Liangchi Z, Xinhua Y (2015) A new error measurement method to identify all six error parameters of a rotational axis of a machine tool. Int J Mach Tools Manuf 88:1–8

Song ZY, Cui YW (2009) S-shape detection test piece and a detection method for detection the precision of the numerical control milling machine. United States, Invention Patent, US8061052B2

Yamaguchi F (1988) Curves and surfaces in computer aided geometric design. Springer

Zhang YM, Lin XL, Wang XD, Cai GQ (2004) The study on the dynamic characteristic of high speed machine tool and experiment validate. Mater Sci Forum: 471–472

Ratchev S, Govender E, Nikov S et al (2003) Force and deflection modeling in milling of low-rigidity complex parts. J Mater Process Technol 143–144:796–801

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, W., Jiang, Z., Tao, W. et al. A new test part to identify performance of five-axis machine tool—part I: geometrical and kinematic characteristics of S part. Int J Adv Manuf Technol 79, 729–738 (2015). https://doi.org/10.1007/s00170-015-6870-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6870-3