Abstract

Incremental in-plane bending (IIB) is a new and advanced flexible manufacturing technology for small-lot production of strip with various bending radii. The strip of sheet metal is bent incrementally by a beating inclined punch. The bending radius is strongly affected by mechanical properties of the material, geometry of the strip, and processing parameters. It is difficult to predict the bending radius due to the complex synergistic effects of the controlling parameters. How to predict the bending radius accurately has therefore become a key point to be urgently solved in the development of this advanced forming technology. In this paper, a model based on a back propagation neural network (BPNN) is introduced to reveal the relationship of bending radius with angle of die α, indentation s, pitch p, and width of strip w. Out of 14 different BPNN architectures trained, the 4-9-9-1 BPNN with two hidden layers having nine neurons trained with the Levenberg-Marquardt algorithm (trainlm) is found to be the optimum network model, and the prediction error is less than 2 % on average. Otherwise, a 1-9-9-4 reverse BPNN is developed to build the processing window for a given bending radius. Meanwhile, taking section moment of inertia I as a quantitative index of forming stability, α, p, s, w 0 are optimized as design variables in order to make objective functions of I maximized simultaneously. Finally, to verify its predictive capability, the present approach is applied to a case study, and the optimal combination of parameters for stable forming during IIB is obtained.

Similar content being viewed by others

References

Li Z, Yang H, Li H, Li H (2011) A new model for precision control of the radius in in-plane roll-bending of strip considering rolls and stand deflections. J Mater Process Technol 211:2072–2084. doi:10.1016/j.jmatprotec.2011.07.003

Li Z, Yang H, Li H, Xu J (2010) An accurate 3D-FE based radius prediction model for in-plane roll-bending of strip considering spread effects. Comput Mater Sci 50:666–677. doi:10.1016/j.commatsci.2010.09.032

Liu N, Yang H, Li H, Li ZJ (2014) A hybrid method for accurate prediction of multiple instability modes in in-plane roll-bending of strip. J Mater Process Technol 214:1173–1189. doi:10.1016/j.jmatprotec.2013.12.010

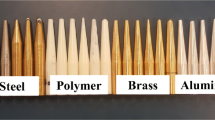

Jin Y, Kuboki T, Murata M (2005) Influence of strip materials on behavior of incremental in-plane bending. J Mater Process Technol 162–163:190–195. doi:10.1016/j.jmatprotec.2005.02.175

Jin Y, Murata M (2004) Influence of pitch and cross-sectional ratio of strip of sheet metal on incremental in-plane bending. J Mater Process Technol 155–156:1810–1814. doi:10.1016/j.jmatprotec.2004.04.357

Strobach P (2011) Solving cubics by polynomial fitting. J Comput Appl Math 235:3033–3052. doi:10.1016/j.cam.2010.12.025

Gan F, Ruan G, Mo J (2006) Baseline correction by improved iterative polynomial fitting with automatic threshold. Chemom Intell Lab Syst 82:59–65. doi:10.1016/j.chemolab.2005.08.009

Mondal S, Bandyopadhyay A, Pal PK (2014) Application of artificial neural network for the prediction of laser cladding process characteristics at Taguchi-based optimized condition. Int J Adv Manuf Technol 70:2151–2158. doi:10.1007/s00170-013-5393-z

Ghatarband M, Asadi ZA, Mazinani S, Kalaee MR, Shiri ME (2014) Predicting mechanical properties of elastomeric modified nylon blend using adaptive neuro-fuzzy interference system and neural network. Int J Adv Manuf Technol. doi:10.1007/s00170-014-6294-5

Manoochehri M, Kolahan F (2014) Integration of artificial neural network and simulated annealing algorithm to optimize deep drawing process. Int J Adv Manuf Technol 73:241–249. doi:10.1007/s00170-014-5788-5

Ravi AM, Murigendrappa SM, Mukunda PG (2014) Experimental investigation on thermally enhanced machining of high-chrome white cast iron and to study its machinability characteristics using Taguchi method and artificial neural network. Int J Adv Manuf Technol 72:1439–1454. doi:10.1007/s00170-014-5752-4

Zheng J, Wang Q, Zhao P, Wu C (2009) Optimization of high-pressure die-casting process parameters using artificial neural network. Int J Adv Manuf Technol 44:667–674. doi:10.1007/s00170-008-1886-6

Hsiang S, Ho H (2004) Application of finite element method and artificial neural network to the die design of radial forging processes. Int J Adv Manuf Technol 24:700–707. doi:10.1007/s00170-003-1786-8

Singh SK, Kumar DR (2005) Application of a neural network to predict thickness strains and finite element simulation of hydro-mechanical deep drawing. Int J Adv Manuf Technol 25:101–107. doi:10.1007/s00170-003-1842-4

Chamekh A, Bel Hadj Salah H, Hambli R (2009) Inverse technique identification of material parameters using finite element and neural network computation. Int J Adv Manuf Technol 44:173–179. doi:10.1007/s00170-008-1809-6

Yuguang Z, Kai X, Dongyan S (2013) An improved artificial neural network for laser welding parameter selection and prediction. Int J Adv Manuf Technol 68:755–762. doi:10.1007/s00170-013-4796-1

Sanjari M, Taheri AK, Movahedi MR (2009) An optimization method for radial forging process using ANN and Taguchi method. Int J Adv Manuf Technol 40:776–784. doi:10.1007/s00170-008-1371-2

Lin JC (2002) Prediction of rolling force and deformation in three-dimensional cold rolling by using the finite-element method and a neural network. Int J Adv Manuf Technol 20:799–806. doi:10.1007/s001700200219

Cook DF, Ragsdale CT, Major RL (2000) Combining a neural network with a genetic algorithm for process parameter optimization. Eng Appl Artif Intell 13:391–396. doi:10.1016/S0952-1976(00)00021-X

Wang J, Wu X, Thomson PF, Flitman A (2000) A neural networks approach to investigating the geometrical influence on wrinkling in sheet metal forming. J Mater Process Technol 105:215–220. doi:10.1016/S0924-0136(00)00534-3

Ambrogio G, Filice L, Guerriero F, Guido R, Umbrello D (2011) Prediction of incremental sheet forming process performance by using a neural network approach. Int J Adv Manuf Technol 54:921–930. doi:10.1007/s00170-010-3011-x

Elangovan K, Sathiya Narayanan C, Narayanasamy R (2010) Modelling of forming limit diagram of perforated commercial pure aluminium sheets using artificial neural network. Comput Mater Sci 47:1072–1078. doi:10.1016/j.commatsci.2009.12.016

Fu Z, Mo J (2011) Springback prediction of high-strength sheet metal under air bending forming and tool design based on GA–BPNN. Int J Adv Manuf Technol 53:473–483. doi:10.1007/s00170-010-2846-5

Liu W, Liu Q, Ruan F, Liang Z, Qiu H (2007) Springback prediction for sheet metal forming based on GA-ANN technology. J Mater Process Technol 187–188:227–231. doi:10.1016/j.jmatprotec.2006.11.087

Li H, Yang H, Zhang ZY, Li GJ, Liu N, Welo T (2014) Multiple instability-constrained tube bending limits. J Mater Process Technol 214:445–455. doi:10.1016/j.jmatprotec.2013.09.027

Hosford WF (2011) Metal forming: mechanics and metallurgy. Cambridge University Press, New York

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, N., Yang, H., Li, H. et al. BP artificial neural network modeling for accurate radius prediction and application in incremental in-plane bending. Int J Adv Manuf Technol 80, 971–984 (2015). https://doi.org/10.1007/s00170-015-7075-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7075-5