Abstract

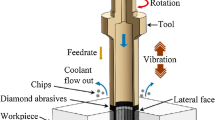

The cutting temperature and cutting force are some of the main factors that influence the surface quality of carbon fiber-reinforced polymer (CFRP). However, few investigations have been done on cutting temperature because it is difficult to capture the dynamic response of the temperature measurement system. Degradation of resin will occur within the machined surface or surface layer as the temperature exceeds the glass-transition temperature of the resin matrix. In this research, the relationship between cutting parameters and cutting temperature, cutting force were developed by response surface methodology (RSM). The experiments were designed using the tool-workpiece thermocouple technique. Taking into consideration the effect of the glass-transition temperature, the influence of cutting force and cutting temperature on surface quality of CFRP was analyzed. Analysis results showed that Spindle speed is the key parameter which influenced the cutting temperature while feed rate is the key parameter which influenced the cutting force in milling of CFRP. When the cutting temperature exceeds the glass-transition temperature (T g), the matrix cannot provide enough support to the fibers, and the machining quality of composite material is poor.

Similar content being viewed by others

References

Gilpin A (2009) Tool solutions for machining composites. Reinf Plast 53(6):30–33

Silva D, Pamies Teixeira J, Machado C (2014) Methodology analysis for evaluation of drilling-induced damage in composites. Int J Adv Manuf Technol 71(9–12):1919–1928. doi:10.1007/s00170-014-5616-y

Qi Z, Zhang K, Cheng H, Wang D, Meng Q (2015) Microscopic mechanism based force prediction in orthogonal cutting of unidirectional CFRP. Int J Adv Manuf Technol :1–11. doi:10.1007/s00170-015-6895-7

Koplev A (1980) Cutting of CFRP with single edge tools. Adv Compos Mater 2:1597–1605

Hocheng H, Puw HY, Huang Y (1993) Preliminary study on milling of unidirectional carbon fibre-reinforced plastics. Compos Manuf 4(2):103–108

Davim JP, Reis P, António CC (2004) A study on milling of glass fiber reinforced plastics manufactured by hand-lay up using statistical analysis (ANOVA). Compos Struct 64(3–4):493–500

Davim JP, Reis P (2005) Damage and dimensional precision on milling carbon fiber-reinforced plastics using design experiments. J Mater Process Technol 160(2):160–167

Palanikumar K, Karunamoorthy L, Karthikeyan R (2006) Assessment of factors influencing surface roughness on the machining of glass fiber-reinforced polymer composites. Mater Des 27(10):862–871

Palanikumar K, Prakash S, Shanmugam K (2008) Evaluation of delamination in drilling GFRP composites. Mater Manuf Process 23(8):858–864

López de Lacalle N, Lamikiz A, Campa FJ, Valdivielso AF, Etxeberria I (2009) Design and test of a multitooth tool for CFRP milling. J Compos Mater 43(26):3275–3290

Kilickap E (2010) Optimization of cutting parameters on delamination based on Taguchi method during drilling of GFRP composite. Expert Syst Appl 37(8):6116–6122

Kalla D, Sheikh-Ahmad J, Twomey J (2010) Prediction of cutting forces in helical end milling fiber reinforced polymers. Int J Mach Tools Manuf 50(10):882–891

Faria PE, Rubio JCC, Abrao AM, Davim JP (2010) The influence of tool wear on delamination when drilling glass fibre reinforced epoxy composite with high speed steel and cemented carbide tools. Int J Mater Prod Technol 37(1):129–139

Tsao CC, Chiu YC (2011) Evaluation of drilling parameters on thrust force in drilling carbon fiber reinforced plastic (CFRP) composite laminates using compound core-special drills. Int J Mach Tools Manuf 51(9):740–744

Hintze W, Hartmann D, Schütte C (2011) Occurrence and propagation of delamination during the machining of carbon fibre reinforced plastics (CFRPs) – An experimental study. Compos Sci Technol 71(15):1719–1726

Krishnaraj V, Prabukarthi A, Ramanathan A, Elanghovan N, Senthil Kumar M, Zitoune R, Davim JP (2012) Optimization of machining parameters at high speed drilling of carbon fiber reinforced plastic (CFRP) laminates. Compos Part B 43(4):1791–1799

Erkan Ö, Işık B, Çiçek A, Kara F (2013) Prediction of damage factor in end milling of glass fibre reinforced plastic composites using artificial neural network. Appl Compos Mater 20(4):517–536

Karpat Y, Bahtiyar O, Değer B (2012) Mechanistic force modeling for milling of unidirectional carbon fiber reinforced polymer laminates. Int J Mach Tools Manuf 56:79–93

Pecat O, Rentsch R, Brinksmeier E (2012) Influence of milling process parameters on the surface integrity of CFRP. Procedia CIRP 1:466–470

Hintze W, Hartmann D (2013) Modeling of delamination during milling of unidirectional CFRP. Procedia CIRP 8:444–449

Chibane H, Morandeau A, Serra R, Bouchou A, Leroy R (2013) Optimal milling conditions for carbon/epoxy composite material using damage and vibration analysis. Int J Adv Manuf Technol 68(5–8):1111–1121

Yashiro T, Ogawa T, Sasahara H (2013) Temperature measurement of cutting tool and machined surface layer in milling of CFRP. Int J Mach Tools Manuf 70:63–69

Azmi AI, Lin RJT, Bhattacharyya D (2013) Machinability study of glass fibre-reinforced polymer composites during end milling. Int J Adv Manuf Technol 64(1–4):247–261

Phadnis VA, Makhdum F, Roy A, Silberschmidt VV (2013) Drilling in carbon/epoxy composites: experimental investigations and finite element implementation. Compos A: Appl Sci Manuf 47:41–51

Madhavan V, Lipczynski G, Lane B, Whitenton E (2014) Fiber orientation angle effects in machining of unidirectional CFRP laminated composites. J Manuf Process (0)

Sasahara H, Kikuma T, Koyasu R, Yao Y (2014) Surface grinding of carbon fiber reinforced plastic (CFRP) with an internal coolant supplied through grinding wheel. Precis Eng 38(4):775–782

Haddad M, Zitoune R, Eyma F, Castanie B (2014) Study of the surface defects and dust generated during trimming of CFRP: influence of tool geometry, machining parameters and cutting speed range. Compos A: Appl Sci Manuf 66:142–154

Zenia S, Ben Ayed L, Nouari M, Delamézière A (2014) Numerical analysis of the interaction between the cutting forces, induced cutting damage, and machining parameters of CFRP composites. Int J Adv Manuf Technol :1–16

Chatterjee A (2009) Thermal degradation analysis of thermoset resins. J Appl Polym Sci 114(3):1417–1425

Sun Y, Sun J, Li J, Xiong Q (2014) An experimental investigation of the influence of cutting parameters on cutting temperature in milling Ti6Al4V by applying semi-artificial thermocouple. Int J Adv Manuf Technol 70(5–8):765–773

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H., Sun, J., Li, J. et al. Evaluation of cutting force and cutting temperature in milling carbon fiber-reinforced polymer composites. Int J Adv Manuf Technol 82, 1517–1525 (2016). https://doi.org/10.1007/s00170-015-7479-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7479-2