Abstract

Aluminum/graphite (Al/Gr) composites have been used as self-lubricating materials due to the superior lubricating effect of graphite during sliding. This paper summarizes various tribological aspects of self-lubricating aluminum composites. The influence of various factors such as (a) material factors, graphite size and volume fraction, and (b) mechanical factors, applied load and sliding speed on the tribological properties of self-lubricating aluminum composites, is discussed. Furthermore, the tribological properties of self-lubricating composites as a function of these parameters and the active wear mechanism involved in various systems are discussed. Bringing self-lubricating composites into different operating systems is a solution to reduce the use of external toxic petroleum-based lubricants in sliding contacts in a way to help the environment and reduce energy dissipation in industrial components for strategies toward sustainability and energy efficiency.

Similar content being viewed by others

References

Menezes PL, Sudeep PI, Michael N, Satish VK, Michael RL (2013) Tribology for Scientists and Engineers. Springer, New York

Rohatgi PK, Meysam T-K, Emad O, Michael RL, Pradeep LM (2013) Tribology of metal matrix composites, in Tribology for scientists and engineers. Springer, New York, pp 233–268

Menezes PL, Michael N, Satish VK, Michael RL (2013) Friction and wear, in tribology for scientists and engineers. Springer, New York, pp 43–91

Alahelisten A et al (1993) On the wear of aluminium and magnesium metal matrix composites. Wear 165(2):221–226

Föhl J, Weissenberg T, Wiedemeyer J (1989) General aspects for tribological applications of hard particle coatings. Wear 130(2):275–288

Alpas A, Zhang J (1994) Effect of microstructure (particulate size and volume fraction) and counterface material on the sliding wear resistance of particulate-reinforced aluminum matrix composites. Metall Mater Trans A 25(5):969–983

Zhou R, Jiang Y, Lu D (2003) The effect of volume fraction of WC particles on erosion resistance of WC reinforced iron matrix surface composites. Wear 255(1):134–138

Dong S, Tu J, Zhang X (2001) An investigation of the sliding wear behavior of Cu-matrix composite reinforced by carbon nanotubes. Mater Sci Eng A 313(1):83–87

Diler EA, Ipek R (2013) Main and interaction effects of matrix particle size, reinforcement particle size and volume fraction on wear characteristics of Al–SiC < sub > p</sub > composites using central composite design. Compos Part B 50:371–380

Kumar S, Balasubramanian V (2010) Effect of reinforcement size and volume fraction on the abrasive wear behaviour of AA7075 Al/SiC < sub > p</sub > P/M composites—a statistical analysis. Tribol Int 43(1):414–422

Karamış M et al (2012) The effects of different ceramics size and volume fraction on wear behavior of Al matrix composites (for automobile cam material). Wear 289:73–81

Shafiei-Zarghani A, Kashani-Bozorg SF, Zarei-Hanzaki A (2009) Microstructures and mechanical properties of Al/Al2O3 surface nano-composite layer produced by friction stir processing. Mater Sci Eng A 500:87.91

Ghasemi-Kahrizsangi A, Kashani-Bozorg SF (2012) Microstructure and mechanical properties of steel/TiC nano-composite surface layer produced by friction stir processing. Surf Coat Technol 209:15–22

Sharma SC (2001) The sliding wear behavior of Al6061–garnet particulate composites. Wear 249:1036–1045

Rohatgi PK et al (2011) Tribological behavior of aluminum micro-and nano-composites. Int J Aerosp Innov 3(3):153–162

Moghadam AD et al (2014) Functional metal matrix composites: self-lubricating, self-healing, and nanocomposites-an outlook. JOM 66(6):1–10

Basavarajappa S et al (2007) Influence of sliding speed on the dry sliding wear behaviour and the subsurface deformation on hybrid metal matrix composite. Wear 262:1007–1012

Wilson S, Alpas A (1997) Wear mechanism maps for metal matrix composites. Wear 212(1):41–49

Deuis RL, Subramanian C, Yellup JM (1997) Dry sliding wear of aluminium composites—a review. Compos Sci Technol 57:415–435

Hosking F et al (1982) Composites of aluminium alloys: fabrication and wear behaviour. J Mater Sci 17(2):477–498

Seeman M et al (2010) Study on tool wear and surface roughness in machining of particulate aluminum metal matrix composite-response surface methodology approach. Int J Adv Manuf Technol 48(5–8):613–624

Rao R et al (2013) Dry sliding wear maps for AA7010 (Al–Zn–Mg–Cu) aluminium matrix composite. Tribol Int 60:77–82

Mondal DP, Das S (2006) High stress abrasive wear behaviour of aluminium hard particle composites: effect of experimental parameters, particle size and volume fraction. Tribol Int 39(6):470–478

Rohatgi, PK, et al (2013) Synthesis and properties of metal matrix nanocomposites (MMNCS), syntactic foams, self lubricating and self‐healing metals. in PRICM: 8 pacific rim International Congress on Advanced Materials and Processing. John Wiley

Rawal SP (2001) Metal-matrix composites for space applications. JOM 53(4):14–17

Reboul M, Baroux B (2011) Metallurgical aspects of corrosion resistance of aluminium alloys. Mater Corros 62(3):215–233

Molina J-M et al (2008) Thermal conductivity of aluminum matrix composites reinforced with mixtures of diamond and SiC particles. Scr Mater 58(5):393–396

Recoules V et al (2002) Electrical conductivity of hot expanded aluminum: experimental measurements and ab initio calculations. Phys Rev E 66(5):056412

LI GC et al (2012) Damping capacity of high strength-damping aluminum alloys prepared by rapid solidification and powder metallurgy process. Trans Nonferrous Metals Soc China 22(5):1112–1117

Kumar GV, Rao C, Selvaraj N (2011) Mechanical and tribological behavior of particulate reinforced aluminum metal matrix composites–a review. J Miner Mater Charact Eng 10(01):59

Kathiresan M, Sornakumar T (2010) Friction and wear studies of die cast aluminum alloy-aluminum oxide-reinforced composites. Ind Lubr Tribol 62(6):361–371

Srivastava S et al (2012) Study of the wear and friction behavior of immiscible as cast-Al-Sn/Graphite composite. Int J of Mod Eng Res 2(2):25–42

Sajjadi SA, Zebarjad SM (2014) Microstructural analysis and mechanical properties of aluminum matrix nanocomposites reinforced with uncoated and Cu-coated alumina particles. Mater Sci Eng A 607:81–88

Knowles A et al (2014) Microstructure and mechanical properties of 6061 Al alloy based composites with SiC nanoparticles. J Alloys Compd 615:S401–S405

Yamaguchi M et al (2014) Powder metallurgy routes toward aluminum boron nitride nanotube composites, their morphologies, structures and mechanical properties. Mater Sci Eng A 604:9–17

Liu B et al (2014) Study on the load partition behaviors of high particle content B4C/Al composites in compression. J Compos Mater 48(3):355–364.37

Huang B et al (2014) Study on friction and wear behaviors of aluminium matrix composites reinforced with in situ formed TiB2 particles. Adv Mater Res 900:794–797

Gudlur P et al (2014) On characterizing the mechanical properties of aluminum–alumina composites. Mater Sci Eng A 590:352–359

Ahmadi A, Toroghinejad MR, Najafizadeh A (2014) Evaluation of microstructure and mechanical properties of Al/Al < sub > 2</sub > O < sub > 3</sub>/SiC hybrid composite fabricated by accumulative roll bonding process. Mater Des 53:13–19

Murali M, Sambathkumar M, Saravanan MS (2014) Micro structural and mechanical properties of AA 7075/Tio < sub > 2</sub > in situ composites. Univ J Mater Sci 2(3):49–53

Nagaral M, Bharath V, Auradi V (2013) Effect of Al 2 O 3 particles on mechanical and wear properties of 6061al alloy metal matrix composites. J Mater Sci Eng 2:120

Edalati K et al (2014) Wear resistance and tribological features of pure aluminum and Al–Al < sub > 2</sub > O < sub > 3</sub > composites consolidated by high-pressure torsion. Wear 310(1):83–89

Subramanian RS (2014) Studies on mechanical and tribological behaviour of particulate aluminium metal matrix composites

Shanmughasundaram P, Subramanian R (2013) Wear behaviour of eutectic Al-Si alloy-graphite composites fabricated by combined modified two-stage stir casting and squeeze casting methods. Adv Mater Sci Eng 2013:1–8

Goto H, Suciu CV, Inokuchi T (2009) Friction and wear properties of aluminum-silicon alloy impregnated graphite composite (ALGR-MMC) under lubricated sliding conditions. Tribol Trans 52:331–345

Tabandeh-Khorshid M, Jenabali-Jahromi SA, Moshksar MM (2010) Mechanical properties of tri-modal Al matrix composites reinforced by nano- and submicron-sized Al2O3 particulates developed by wet attrition milling and hot extrusion. Mater Des 31(8):3880–3884

Rohatgi P, Surappa M (1984) Deformation of graphite during hot extrusion of cast aluminum-silicon-graphite particle composites. Mater Sci Eng 62(2):159–162

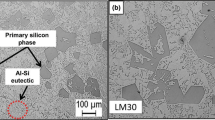

Rao AKP et al (2006) Microstructural and wear behavior of hypoeutectic Al–Si alloy (LM25) grain refined and modified with Al–Ti–C–Sr master alloy. Wear 261(2):133–139

Dwivedi DK (2006) Wear behaviour of cast hypereutectic aluminium silicon alloys. Mater Des 27(7):610–616

Chen M, Perry T, Alpas AT (2007) Ultra-mild wear in eutectic Al–Si alloys. Wear 263(1):552–561

Vencl A, Bobić I, Mišković Z (2008) Effect of thixocasting and heat treatment on the tribological properties of hypoeutectic Al–Si alloy. Wear 264(7):616–623

Bai B, Biswas S (1987) Characterization of dry sliding wear of Al-Si alloys. Wear 120(1):61–74

Menezes PL, Kailas SV (2009) Role of surface texture of harder surface on subsurface deformation. Wear 266(1):103–109

Menezes PL, Kailas SV (2008) Subsurface deformation and the role of surface texture—a study with Cu pins and steel plates. Sadhana 33(3):191–201

Dautzenberg J, Zaat J (1973) Quantitative determination of deformation by sliding wear. Wear 23(1):9–19

Elmadagli M, Perry T, Alpas AT (2007) A parametric study of the relationship between microstructure and wear resistance of Al–Si alloys. Wear 262(1–2):79–92

Dorri Moghadam A et al (2015) Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene–a review. Compos Part B 77:402–420

Omrani E et al (2015) Mechanical and tribological properties of self-lubricating bio-based carbon-fabric epoxy composites made using liquid composite molding. Tribol Int. doi:10.1016/j.triboint.2015.06.007

Clauss FJ (2012) Solid lubricants and self-lubricating solids.Elsevier

Deaquino-Lara R et al (2015) Tribological characterization of Al7075–graphite composites fabricated by mechanical alloying and hot extrusion. Mater Des 67:224–231

Baradeswaran A, Elaya Perumal A (2015) Effect of graphite on tribological and mechanical properties of AA7075 composites. Tribol Trans 58(1):1–6

Zeren A (2015) Effect of the graphite content on the tribological properties of hybrid Al/SiC/Gr composites processed by powder metallurgy. Ind Lubr Tribol 67(3):262–268

Baradeswaran A, Perumal E (2014) Wear and mechanical characteristics of Al 7075/graphite composites. Compos Part B 56:472–476

Baradeswaran A, Perumal AE (2014) Study on mechanical and wear properties of Al 7075/Al2O3/Graphite hybrid composites. Compos Part B 56:464–471

Ravindran P et al (2013) Tribological behaviour of powder metallurgy-processed aluminium hybrid composites with the addition of graphite solid lubricant. Ceram Int 39(2):1169–1182

Wu LL et al (2013) Wear resistance of graphite/aluminium composites that prepared by stirring casting. Adv Mater Res 683:333–338, Trans Tech Publ

Menezes PL et al. (2013) Self-lubricating behavior of graphite-reinforced composites, in tribology for scientists and engineers. Springer 341–389

Menezes PL, Rohatgi PK, Lovell MR (2012) Self-lubricating behavior of graphite reinforced metal matrix composites, in green tribology. Springer 445–480

Radhika N et al (2012) Dry sliding wear behaviour of aluminium/alumina/graphite hybrid metal matrix composites. Ind Lubr Tribol 64(6):359–366

Radhika N, Subramanian R, Prasat SV (2011) Tribological behaviour of aluminium/alumina/graphite hybrid metal matrix composite using taguchi’s techniques. J Miner Mater Charact Eng 10(05):427

Mahdavi S, Akhlaghi F (2011) Effect of the graphite content on the tribological behavior of Al/Gr and Al/30SiC/Gr composites processed by in situ powder metallurgy (IPM) method. Tribol Lett 44(1):1–12

Rajaram G, Kumaran S, Rao TS (2011) Fabrication of Al–Si/graphite composites and their structure–property correlation. J Compos Mater 45(26):2743–2750

Baradeswaran A, Elayaperumal A (2011) Wear characteresitic of Al6061 reinforced with graphite under different loads and sppeds. Adv Mater Res 287–290:998–1002

Suresha S, Sridhara BK (2010) Wear characteristics of hybrid aluminium matrix composites reinforced with graphite and silicon carbide particulates. Compos Sci Technol 70(11):1652–1659

Akhlaghi F, Zare-Bidaki A (2009) Influence of graphite content on the dry sliding and oil impregnated sliding wear behavior of Al 2024–graphite composites produced by in situ powder metallurgy method. Wear 266(1–2):37–45

Jinfeng L et al (2009) Effect of graphite paticle reinforcment on dry sliding wear of SiC/Gr/Al composites. Rare Metal Mater Eng 38(11):1894–1898

Fuentes R et al (2003) Wear behavior of a self-lubricating aluminum/graphite composite prepared by powder metallurgy. Ind Lubr Tribol 55(4):157–161

Guo MLT, Tsao C-YA (2000) Tribological behavior of self-lubricating aluminium/SiC/graphite hybrid composites synthesized by the semi-solid powder-densification method. Compos Sci Technol 60(1):65–74

Ames W, Alpas A (1995) Wear mechanisms in hybrid composites of graphite-20 Pct SiC in A356 aluminum alloy (Al-7 Pct Si-0.3 Pct Mg). Metall Mater Trans A 26(1):85–98

Reeves CJ et al. (2013) Tribology of solid lubricants, in tribology for scientists and engineers. Springer 447–494

Mahdavi S, Akhlaghi F (2011) Effect of the SiC particle size on the dry sliding wear behavior of SiC and SiC–Gr-reinforced Al6061 composites. J Mater Sci 46(24):7883–7894

Saheb DA (2011) Aluminum silicon carbide and aluminum graphite particulate composites. ARPN J Eng and Appl Sci 6(10)

Shams SS, El-Hajjar RF (2013) Effects of scratch damage on progressive failure of laminated carbon fiber/epoxy composites. Int J Mech Sci 67:70–77

Oh S-I et al (2012) Fabrication of carbon nanofiber reinforced aluminum alloy nanocomposites by a liquid process. J Alloys Compd 542(25):111

Nayeb-Hashemi H, Seyyedi J (1989) Study of the interface and its effect on mechanical properties of continuous graphite fiber-reinforced 201 aluminum. Metall Trans A 20(4):727–739

Kiran T et al (2015) Effect of heat treatment on tribological behavior of zinc aluminum alloy reinforced with graphite and SIC particles for journal bearing. Ind Lubr Tribol 67(4):292–300

Mitrović S et al (2012) Tribological potential of hybrid composites based on zinc and aluminium alloys reinforced with SiC and graphite particles. Tribol Ind 34(4):177–185

Kestursatya M, Kim J, Rohatgi P (2001) Friction and wear behavior of a centrifugally cast lead-free copper alloy containing graphite particles. Metall Mater Trans A 32(8):2115–2125

Rohatgi P, Pai B (1980) Seizure resistance of cast aluminium alloys containing dispersed graphite particles of various sizes. Wear 59(2):323–332

Rohatgi P, Pai B (1979) Seizure resistance of cast aluminum alloys containing dispersed graphite particles of different sizes. J Tribol 101(3):376–380

Barekar N et al (2009) Processing of aluminum-graphite particulate metal matrix composites by advanced shear technology. J Mater Eng Perform 18(9):1230–1240

Archard JF, Hirst W (1956) The wear of metals under unlubricated conditions. Proc R Soc Lond A Math Phys Sci 236(1206):397–410

Prasad B, Dan T, Rohatgi P (1987) Pressure-induced improvement in interfacial bonding between graphite and the aluminium matrix in graphitic-aluminium particle composites. J Mater Sci Lett 6(9):1076–1078

Vedula M, Pangborn R, Queeney R (1988) Fibre anisotropic thermal expansion and residual thermal stress in a graphite/aluminium composite. Composites 19(1):55–60

Rohatgi P et al (1976) Improved damping capacity and machinability of graphite particle-aluminum alloy composites. Mater Sci Eng 26(1):115–122

Rohatgi P, Ray S, Liu Y (1992) Tribological properties of metal matrix-graphite particle composites. Int Mater Rev 37:129–152

Kurita H et al (2015) Interfacial microstructure of graphite flake reinforced aluminum matrix composites fabricated via hot pressing. Compos A: Appl Sci Manuf 73:125–131

Akhlaghi F, Pelaseyyed SA (2004) Characterization of aluminum/graphite particulate composites synthesized using a novel method termed “in-situ powder metallurgy”. Mater Sci Eng A 385(1–2):258–266

Hayajneh MT, Hassan AM, Mayyas AT (2009) Artificial neural network modeling of the drilling process of self-lubricated aluminum/alumina/graphite hybrid composites synthesized by powder metallurgy technique. J Alloys Compd 478(1):559–565

Akhlaghi F, Mahdavi S (2011) Effect of the SiC content on the tribological properties of hybrid Al/Gr/SiC composites processed by in situ powder metallurgy (IPM) method. Adv Mater Res 264–265:1878–1886

Chen J, Huang I (2013) Thermal properties of aluminum–graphite composites by powder metallurgy. Compos Part B 44(1):698–703

Krishnan B et al (1980) Performance of an Al-Si-graphite particle composite piston in a diesel engine. Wear 60(1):205–215

Kulkarni SR, Sonawane P, Karnik M (2014) Effect of graphite addition on the mechanical properties of stir cast particulate aluminum metal matrix composite reinforced with alumina and silicon carbide. Appl Mech Mater 612:163–16, Trans Tech Publ

Etter T et al (2004) Strength and fracture toughness of interpenetrating graphite/aluminium composites produced by the indirect squeeze casting process. Mater Sci Eng A 386(1):61–67

Patnaik S et al (2014) Wear characteristics of aluminium-graphite composites produced by stir casting technique. J Mater Metall Eng 4(3):13–20

Dwivedi SK, Patel S (2014) Evaluation of hardness of aluminium/graphite particulate composite fabricated by stir casting route. Evaluation 3(01):26–28

So KP et al (2013) SiC formation on carbon nanotube surface for improving wettability with aluminum. Compos Sci Technol 74:6

Lim J-Y et al (2012) Effects of CNF dispersion on mechanical properties of CNF reinforced A7xxx nanocomposites. Mater Sci Eng A 556:337

Rack H (1988) Advanced materials and manufacturing processes, 3.

Flores-Zamora M et al (2007) Aluminum–graphite composite produced by mechanical milling and hot extrusion. J Alloys Compd 434:518–521

Yang JB et al (2004) The tribological characteristics of A356.2Al alloy/Gr(p) composites. Wear 257:941–952

Das S, Prasad V, Ramachandran T (1989) Microstructure and wear of cast (Al-Si alloy)-graphite composites. Wear 133:173–187

Roy M et al (1992) The effect of participate reinforcement on the sliding wear behavior of aluminum matrix composites. Metall Trans A 23(10):2833–2847

Van Acker K et al (2005) Influence of tungsten carbide particle size and distribution on the wear resistance of laser clad WC/Ni coatings. Wear 258(1):194–202

Tokisue H, Abbaschian G (1978) Friction and wear properties of aluminum-particulate graphite composites. Mater Sci Eng 34(1):75–78

Sannino AP, Rack HJ (1995) Dry sliding wear of discontinuously reinforced aluminum composites: review and discussion. Wear 189(1–2):1–19

Wei Y et al (2011) Characterizations of DLC/MAO composite coatings on AZ80 magnesium alloy. Acta Metall Sin 47(12):1535–1540

Hocheng H et al (1997) Fundamental turning characteristics of a tribology-favored graphite/aluminum alloy composite material. Compos A: Appl Sci Manuf 28(9–10):883–890

Prasad BK, Das S (1991) The significance of the matrix microstructure on the solid lubrication characteristics in aluminum alloys. Mater Sci Eng A 144:229–235

Aylor DM, Moran PJ (1985) Effect of reinforcement on the pitting behavior of aluminum‐base metal matrix composites. J Electrochem Soc 132(6):1277–1281

Gore K, Charles J (1974) Met Technol 1:279

Riahi AR, Alpas AT (2001) The role of tribo-layers on the sliding wear behavior of graphitic aluminum matrix composites. Wear 251(1–12):1396–1407

Prasad SV, Asthana R (2004) Aluminum metal-matrix composites for automotive applications: tribological considerations. Tribol Lett 17:445–453

Altunpak Y, Ay M, Aslan S (2012) Drilling of a hybrid Al/SiC/Gr metal matrix composites. Int J Adv Manuf Technol 60(5–8):513–517

Song J, Han K (1997) Mechanical Properties and solid lubricant wear behavior of Al/Al2O3/C hybrid metal matrix composites fabricated by squeez casting method. J Compos Mater 31(4):316–344

Basavarajappa S et al (2006) Dry sliding wear behavior of Al 2219/SiCp-Gr hybrid metal matrix composites. J Mater Eng Perform 15(6):668–674

Ravindran P et al (2013) Investigation of microstructure and mechanical properties of aluminum hybrid nano-composites with the additions of solid lubricant. Mater Des 51:448–456

Don J (1982) Unlubricated friction and wear in the Cu-Be. PhD thesis: Ohio State University

Chen Z et al (2000) Microstructure and properties of in situ Al/TiB2 composite fabricated by in-melt reaction method. Metall Mater Trans A 31(8):1959–1964

Tjong SC (2007) Novel nanoparticle‐reinforced metal matrix composites with enhanced mechanical properties. Adv Eng Mater 9(8):639–652

Thostenson ET, Li C, Chou T-W (2005) Nanocomposites in context. Compos Sci Technol 65(3):491–516

He F, Han Q, Jackson MJ (2008) Nanoparticulate reinforced metal matrix nanocomposites–a review. Int J Nanopart 1(4):301–309

Singh J, Narang D, Batra NK (2013) Experimental investigation of mechanical and tribological properties of Aa-SiC and Al-Gr metal matrix composite. Int J Eng Sci Technol 5(6):1205–1210

Shivanath R, Sengupta P, Eyre T (1977) Wear of aluminium-silicon alloy. Br Foundryman 70(12):349–356

Eyre T (1980) Wear of aluminium alloys. Microstruct Sci 8:141–151

Babić M et al (2013) Wear properties of A356/10SiC/1Gr hybrid composites in lubricated sliding conditions. Tribol Ind 35(2):148–154

Basavarajappa S, Chandramohan Dry G (2005) Sliding wear behaviour of hybrid metal matrix composites. Mater Sci 11(3):253–257

Singh S (2003) Metal matrix composites: a potential material for futuristic automotive. SAE Technical Paper 26–0038

Kim M et al. (2011) Development of cast-forged knuckle using high strength aluminum alloy. SAE Technical Paper

Sherman AM, Sklad PS (2002) Collaborative development of lightweight metal and alloys for automotive applications. SAE Technical Paper

Hunt WH, Miracle DB (2001) Automotive applications of metal-matrix composites

Miracle DB Hunt W (2004) Automotive applications of metal-matrix composites. Aluminium Consultant Group Inc 1029–1032

Saravana Bhavan K, Suresh S, Vettivel S Synthesis, characterization and mechanical behavior of nickel coated graphite on aluminum matrix composite

Surappa M (2003) Aluminium matrix composites: challenges and opportunities. Sadhana 28(1–2):319–334

Kevorkijan V (2002) Development of Al MMC composites for automotive industry

Varuzan K (2002) Development of Al MMC composites for automotive industry. Yugoslav Association of Metallurgical Engineers YAME

Eliasson J, Sandström R (1995) Applications of aluminium matrix composites. in key engineering materials. Trans Tech Publ

Rice S, Nowotny H, Wayne S (1981) Characteristics of metallic subsurface zones in sliding and impact wear. Wear 74(1):131–142

Author information

Authors and Affiliations

Corresponding authors

Additional information

Emad Omrani and Afsaneh Dorri Moghadam contributed equally to this work.

Rights and permissions

About this article

Cite this article

Omrani, E., Moghadam, A.D., Menezes, P.L. et al. Influences of graphite reinforcement on the tribological properties of self-lubricating aluminum matrix composites for green tribology, sustainability, and energy efficiency—a review. Int J Adv Manuf Technol 83, 325–346 (2016). https://doi.org/10.1007/s00170-015-7528-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7528-x