Abstract

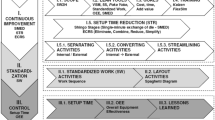

This document is about how to reduce set-up time using Single-Minute Exchange of Die (SMED) on an actual production process of interconnection axles, starting with a production and indicators analysis, followed by time studies, and then the rolling-out of all the SMED stages. The first activity carried out was observation, second assessment, and followed by implementation leading to standardization and the generation of standard manufacturing documents. At this point, training was carried out thereby enabling the validation and assessment of the versatility matrix. Finally, the productivity of the manufacturing cell was evaluated by looking at the new Overall Equipment Effectiveness (OEE) indicator to demonstrate the effectiveness of SMED in reducing start-up times and the fine-tuning of machinery.

Similar content being viewed by others

References

Zambrano Vargas S (2013) La competitividad en los sectores manufacturero y de servicios. Estudio de caso. Criterio Libre 17:177–192

Carrizo Moreira A, Torres Garcez PM (2013) Implementation of the Single Minute Exchange of Die (SMED) methodology in small to medium-sized enterprises : a Portuguese case study. Int J Manag 30(1):66–88

Womack, J.P., D. T. Jones. 1994. From lean production to the lean enterprise. Harvard Bulletin Review, 93–104

Dantas J, Carrizo Moreira A (2011) Novas Perspetivas Tecnológicas nos Processos de Conceção e Desenvolvimento. O Processo de Inovação, Lisboa

Ibarra Miron S, Sarache Castro W, Suárez Garcia M (2004) La estrategia de producción: una aproximación al nuevo paradigma en investigación en manufactura. Revista Universidad Eafit 40(136):65–77

Bessant J, Buckingham J (1993) Innovation and organizational learning: the case of computer-aided production management. Br J Manag 4(4):219–235

Pinto Jiménez, I de J., R. Fernández Ortega, L. Martínez, and G. Kavffmann. 2006. Análisis del énfasis en la innovación en la implantación del ‘MIDDLE-UP-DOWN MANAGMENTMODEL’. Un estudio evolutivo en las empresas manufactureras del país Vasco. Estudios Gerenciales, 2003, 37–60

Shingo S, Dillon AP (1985) A revolution in manufacturing: the SMED system. Productivity press, Cambridge, Massachusetts, p 30

Carrizo Moreira A, Silva Pais GC (2011) Single Minute Exchange of Die: a case study implementation. J Technol 6(1):129–146

Shingo S (2000) Sistema de Troca Rapida de Ferramenta. Bookman Companhia Ed, Porto Alegre, p 328

Holweg M (2006) The genealogy of lean production. J Oper Manag 25:420–437

Fogliatto F, Fagundes P (2003) Troca rápida de ferramentas: proposta metodológica e estudo de caso. Gestão Produção 10(2):163–181

McIntosh R, Culley S, Mileham T, Owen G (2000) A critical evaluation of Shingo’s ‘SMED’ (Single Minute Exchange of Die) methodology. Int J Prod Res 38(11):2377–2395

Monden Y (1984) Produção sem estoques - Uma abordagem prática ao sistema de produção da Toyota. INAM, Sao Paulo

Satolo E, Calarge F (2008) Troca Rápida de Ferramentas: estudo de casos em diferentes segmentos industriais. Exacta 6(2):283–296

Ndahi, H. 2006. Lean manufacturing in a global and competitive market. Technology Teacher, November 14–18.

Efd Induction. 2012. Aplicaciones de calentamiento por inducción. España, 6–8

Higuera O, Florez L, Arroyave J (2008) Diseño de un sistema de enfriamiento para temple de aceros. Sci Tech 14(39):170–175

Universidad de Buenos Aires. 2012. Ensayos Destructivos. Buenos Aires, 15

Escuela Colombiana de Ingeniería Julio Garavito. 2011. Metalografía protocolo. Bogotá, 23

McGovern SM, Gupta SM (2011) Disassembly line: disassembly-line just-in-time in balancing and modeling. McGraw-Hill, New York, Chapter 27

De Ron A, Rooda J (2006) OEE and equipment effectiveness: an evaluation. Int J Prod 44(23):4987–5003

Invernizz, N. 2002. Trabajo polivalente y conocimientos sobre la producción. Tendencias en la industria brasilera. Revista Iberoamericana de Ciencia, Tecnología, Sociedad e Innovación, 3, 7.

Pérez-Duque P, Suárez-Moreno OE (2010) Aplicación para el Diagnóstico y Control de Sistemas Productivos. Ciencia PC 2:88–100

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Morales Méndez, J.D., Silva Rodríguez, R. Set-up reduction in an interconnection axle manufacturing cell using SMED. Int J Adv Manuf Technol 84, 1907–1916 (2016). https://doi.org/10.1007/s00170-015-7845-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7845-0