Abstract

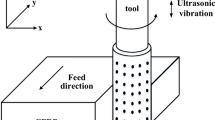

The modes of material removal in machining of brittle materials consist of ductile mode and brittle mode. It is believed that there is an obvious distinction between the energy expenditures in these two modes. In this paper, the specific energies expended in ductile and brittle modes removal are modeled as a function of ultrasonic vibration parameters, grinding parameters, and work-material intrinsic properties. An approach to predict the critical cutting depth for ductile-brittle transition in ultrasonic vibration assisted grinding of glasses is proposed based on the analytical expressions for the specific cutting energies consumed in ductile and brittle modes of machining. The critical cutting depth is identified at the point where both curves of specific energies expended in ductile and brittle modes intersect. Scratching tests of BK7 and JGS1 optical glasses are conducted to verify the validity of the proposed model. Experimental results are found to correspond well with the predicted data.

Similar content being viewed by others

References

Brinksmeier E, Mutlugunes Y, Klocke F, Aurich JC, Shore P, Ohmori H (2010) Ultra-precision grinding. Manuf Technol 59(2):652–671. doi:10.1016/j.cirp.2010.05.001

Ono T, Matsumura T (2008) Influence of tool inclination on brittle fracture in glass cutting with ball end mills. J Mater Process Technol 202(1–3):61–69. doi:10.1016/j.jmatprotec.2007.08.068

Fang FZ, Zhang GX (2004) An experimental study of optical glass machining. Int J Adv Manuf Technol 23(3–4):155–160. doi:10.1007/s00170-003-1576-3

Zhou M, Wang XJ, Ngoi BKA, Gan JGK (2002) Brittle-ductile transition in diamond cutting of glasses with the aid of ultrasonic vibration. J Mater Process Technol 121(2–3):243–251. doi:10.1016/S0924-0136(01)01262-6

Komanduri R (1996) On material removal mechanisms in finishing of advanced ceramics and glasses. Manuf Technol 45(1):509–514. doi:10.1016/S0007-8506(07)63113-8

Venkatesh VC, Inasaki I, Toenshof HK, Nakagawa T, Marinescu ID (1995) Observations on polishing and ultraprecision machining of semi-conductor substrate materials. Manuf Technol 44(2):611–618. doi:10.1016/S0007-8506(07)60508-3

Lv DX, Huang YH, Tang YJ, Wang HX (2012) Relationship between subsurface damage and surface roughness of glass BK7 in rotary ultrasonic machining and conventional grinding processes. Int J Adv Manuf Technol 67(1):613–622. doi:10.1007/s00170-012-4509-1

Liu K, Li XP, Rahman M (2008) Characteristics of ultrasonic vibration-assisted ductile mode cutting of tungsten carbide. Int J Adv Manuf Technol 35(7–8):833–841. doi:10.1007/s00170-006-0761-6

Fang FZ, Ni H, Gong H (2014) Rotary ultrasonic machining of hard and brittle materials. Nanotechnol Precis Eng 12(3):227–234. doi:10.13494/j.npe.20130106

Mahaddalkar PM, Miller MH (2014) Force and thermal effects in vibration-assisted grinding. Int J Adv Manuf Technol 71(5–8):1117–1122. doi:10.1007/s00170-013-5537-1

Zhang JH, Zhao Y, Tian FQ, Zhang S, Guo LS (2015) Kinematics and experimental study on ultrasonic vibration-assisted micro end grinding of silica glass. Int J Adv Manuf Technol 78(9):1893–1904. doi:10.1007/s00170-014-6761-z

Feng PF, Liang GQ, Zhang JF (2014) Ultrasonic vibration-assisted scratch characteristics of silicon carbide-reinforced aluminum matrix composites. Ceram Int 40(7):10817–10823. doi:10.1016/j.ceramint.2014.03.073

Bifano TG, Fawcett SC (1991) Specific grinding energy as an in-process control variable for ductile-regime grinding. Precis Eng 13(4):256–262. doi:10.1016/0141-6359(91)90003-2

Zhang XQ, Kumara AS, Rahman M, Nath C, Liu K (2012) An analytical force model for orthogonal elliptical vibration cutting technique. J Manuf Process 14(3):378–387. doi:10.1016/j.jmapro.2012.05.006

Qiao GC (2013) Research on machined surface integrity in ultrasonic vibration mill-grinding of silicon nitride ceramics. Ph.D. Dissertation, Harbin Institute of Technology

Marshall DB, Lawn BR (1986) Indentation of brittle materials. In: Blau PJ, Lawn BR (eds) Microindentation techniques in materials science and engineering. American society for testing and materials, Philadelphia, pp 26–46

Hamzah E, Sudin I, Khoo CY (2008) A review on the rotary ultrasonic machining of advanced ceramics. J Mekanikal 25:9–23

Blake PN, Scattergood RO (1990) Ductile-regime machining of germanium and silicon. J Am Ceram Soc 73(4):949–957. doi:10.1111/j.1151-2916.1990.tb05142.x

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, M., Zhao, P. Prediction of critical cutting depth for ductile-brittle transition in ultrasonic vibration assisted grinding of optical glasses. Int J Adv Manuf Technol 86, 1775–1784 (2016). https://doi.org/10.1007/s00170-015-8274-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8274-9