Abstract

Titanium alloys are widely used in aerospace, biomedical, and other engineering areas due to their superior properties. However, machining of titanium alloys has always been a challenge due to the high temperatures and tool wear rates. Dry machining has a limited range of permissible cutting conditions and is hence not suitable for industrial production. As a solution, flood cooling using cutting fluids is conventionally used to reduce the cutting temperatures. However, it is often discouraged in light of the associated environmental and health hazards. In order to achieve sustainable machining, different strategies for applying the cutting fluids are developed. Some of the prominent methods include minimum quantity lubrication (MQL), minimum quantity cooled lubrication (MQCL), and cryogenic cooling. This paper provides a comprehensive review of the available recent literature on such studies. Each of these techniques and results obtained in the studies has been discussed with emphasis on the advantages and limitations of each method. Major conclusions drawn are that coated carbides are better and machinability is greatly affected by the microstructure of the material. MQL certainly improved compared to other methods while cryogenic or super cooled cutting fluid application (MQCL) has been found to be better for specific situations. Use of nanofluids for titanium is not very popular among the researchers.

Similar content being viewed by others

References

Shokrani A, Dhokia V, Newman ST (2012) Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int J Mach Tools and Manuf 57:83–101

Singh P, Pungotra H, Kalsi NS (2016) On the complexities in machining titanium alloys in CAD/CAM. In: Robotics and factories of the future. Springer, New Delhi, pp 499–507

Abdalla HS, Baines W, McIntyre G, Slade C (2007) Development of novel sustainable neat-oil metal working fluids for stainless steel and titanium alloy machining part 1 formulation development. Int J Adv Manuf Tech 34(1–2):21–33

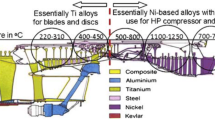

Ezugwu EO, Bonney J, Yamane Y (2003) An overview of the machinability of aeroengine alloys. J Matr Proc Tech 134(2):233–225

Welsch G, Boyer R, Collings E W (Eds) (1993) Materials properties handbook: titanium alloys ASM international USA

Pan W (2014) The machining of titanium alloys with polycrystalline diamond tools (Doctoral dissertation, RMIT University Melbourne, Australia).

Sun FJ, Qu SG, Pan YX, Li XQ, L FL (2015) Effects of cutting parameters on dry machining Ti-6Al-4V alloy with ultra-hard tools. Int J Adv Manuf Tech 79(1–4):351–360

Pervaiz S, Deiab I, Durras B (2013) Power consumption and tool wear assessment when machining titanium alloys. Int J Precs Engg and Manuf 14(6):925–936

Sun S, Brandt M, Dargusch MS (2015) Effect of tool wear on chip formation during dry machining of Ti-6Al-4V alloy, part 2: effect of tool failure modes. J Engg Manuf. doi:10.1177/0954405415600011

Arrazola PJ, Garay A, Iriarte LM, Armendia M, Marya S, Le Maitre F (2009) Machinability of titanium alloys (Ti6Al4V and Ti555 3). J Matr Proc Tech 209(5):2223–2230

Da Silva RB, Machado ÁR, Ezugwu EO, Bonney J, Sales WF (2013) Tool life and wear mechanisms in high speed machining of Ti–6Al–4V alloy with PCD tools under various coolant pressures. J Matr Proc Tech 213(8):1459–1464

Pawar P, Patil S, Kekade S, Pawar S, Singh R (2016) Effect of high pressure coolant on tool wear phenomenon during machining of titanium alloy Ti6Al4V. In Appl Mech and Matrs 826:93–98 Trans Tech Publications

Sui X, Li G, Qin X, Yu H, Zhou X, Wang K, Wang Q (2016) Relationship of microstructure, mechanical properties and titanium cutting performance of TiAlN/TiAlSiN composite coated tool. Ceramics Int 42(6):7524–7532

Hollerweger R, Riedl H, Paulitsch J, Arndt M, Rachbauer R, Polcik P, Primig S, Mayrhofer PH (2014) Origin of high temperature oxidation resistance of Ti–Al–Ta–N coatings. Surf Coat Technol 257:78–86

Komanduri R, Turkovich BFV (1981) New observations on the mechanism of chip formation when machining titanium alloys. Wear 69(2):179–188

Gupta K, Laubscher RF (2016) Sustainable machining of titanium alloys: a critical review. J Engg Manuf. doi:10.1177/0954405416634278

Sharif S, Rahim EA (2007) Performance of coated-and uncoated-carbide tools when drilling titanium alloy—Ti–6Al4V. J Matr Proc Tech 185(1):72–76

Cantero JL, Tardio MM, Canteli JA, Marcos M, Miguelez MH (2005) Dry drilling of alloy Ti–6Al–4V. Int J Mach Tools and Manuf 45(11):1246–1255

Armendia M, Garay A, Iriarte LM, Arrazola PJ (2010) Comparison of the machinabilities of Ti6Al4V and TIMETAL® 54M using uncoated WC–Co tools. J Matr Proc Tech 210(2):197–203

Armendia M, Osborne P, Garay A, Belloso J, Turner S, Arrazola PJ (2012) Influence of heat treatment on the machinability of titanium alloys. Matrs and Manuf Proc 27(4):457–461

Nouari M, Makich H (2014) On the physics of machining titanium alloys: interactions between cutting parameters, microstructure and tool wear. Metals 4(3):335–358

Khanna N, Sangwan KS (2013) Machinability analysis of heat treated Ti64, Ti54M and Ti10. 2.3 titanium alloys. Int J Precs Engg and Manuf 14(5):719–724

Lütjering G, Williams JC (2003) Titanium. Springer, Berlin

Paulo D (2014) Machining of titanium alloys. Springer, Berlin

Joshi S, Pawar P, Tewari A, Joshi SS (2014) Tool wear mechanisms in machining of three titanium alloys with increasing β-phase fraction. J Engg Manuf 228(9):1090–1103

Sacristan I, Garay A, Hormaetxe E, Aperribay J, Arrazola PJ (2016) Influence of oxygen content on the machinability of Ti-6Al-4V alloy. Int J Adv Manuf Tech. doi:10.1007/s00170-015-8317-2

Barkia B, Doquet V, Couzinié JP, Guillot I, Héripré E (2015) In situ monitoring of the deformation mechanisms in titanium with different oxygen contents. Mtrls Sci and Engg: A 636:91–102

Zhang X, Shivpuri R, Srivastava A (2016) Chip fracture behavior in the high-speed machining of titanium alloys. J Manuf Sci and Engg 138(8):081001

Vijay S, Krishnaraj V (2013) Machining parameters optimization in end milling of Ti-6Al-4V. Procedia Engg 64:1079–1088

Mamedov A, Lazoglu I (2016) Thermal analysis of micro milling titanium alloy Ti–6Al–4 V. J Mater Process Technol 229:659–667

Zhang X, Shivpuri R, Srivastava AK (2015) Role of tool flank wear and machining speed in developing of residual stress in machined surface during high speed machining of titanium alloys. In ASME 2015 Int Manuf Sci and Engg Conf, North Carolina, USA. Paper No. MSEC2015-9401, V001T02A033 doi:10.1115/MSEC2015-9401.

Zhu Z, Sun J, Li J, Huang P (2016) Investigation on the influence of tool wear upon chip morphology in end milling titanium alloy Ti6Al4V. Int J Adv Manuf Tech:1477–1485 Doi:10.1007/s00170-015-7690-1

Wagner V, Baili M, Dessein G (2015) The relationship between the cutting speed, tool wear, and chip formation during Ti-5553 dry cutting. Int J Adv Manuf Tech 76(5–8):893–912

Sima M (2015) Physics-based simulation and reliability modeling for multi-objective optimization of advanced cutting tools in machining titanium alloys, Doctoral dissertation, Rutgers University, New Brunswick

Nithyanandam J, Das SL, Palanikumar K (2015) Influence of cutting parameters in machining of titanium alloy. Ind J Sci and Tech 8(S8):556–562

Sutter G, List G (2013) Very high speed cutting of Ti–6Al–4V titanium alloy–change in morphology and mechanism of chip formation. Int J Mach Tools and Manuf 66:37–43

Wang B, Liu Z (2013) Investigations on the chip formation mechanism and shear localization sensitivity of high-speed machining Ti6Al4V. Int J Adv Manuf Tech 75(5–8):1065–1076

Wu H, Zhang S (2015) Effects of cutting conditions on the milling process of titanium alloy Ti6Al4V. Int J Adv Manuf Tech 77(9–12):2235–2240

Rashid RR, Palanisamy S, Sun S, Dargusch MS (2016) Tool wear mechanisms involved in crater formation on uncoated carbide tool when machining Ti6Al4V alloy. Int J Adv Manuf Tech 83(9):1457–1465

Wagner V, Duc E (2014) Study of Ti-1023 milling with toroidal tool. Int J Adv Manuf Technol 75(9–12):1473–1491

Prasanna J, Karunamoorthy L, Raman MV, Prashanth S, Chordia DR (2014) Optimization of process parameters of small hole dry drilling in Ti–6Al–4V using Taguchi and grey relational analysis. Measurement 48:346–354

Yang D, Liu Z (2015) Surface topography analysis and cutting parameters optimization for peripheral milling titanium alloy Ti–6Al–4V. Int J Refractory Metals and Hard Mat 51:192–200

Byers JP (ed) (2006) Metalworking fluids. 2nd ed. CRC Press, USA

Childs T (2000) Metal machining: theory and applications. Butterworth-Heinemann, USA

Narutaki N, Murakoshi A, Motonishi S, Takeyama H (1983) Study on machining of titanium alloys. CIRP Annals-Manuf Tech 32(1):65–69 doi:10.1016/s0007-8506(07)63362-9

Nambi M, Paulo D (2011) Influence of coolant in machinability of titanium alloy (Ti-6Al-4V). J Surf Eng Mat and Adv Tech 1(1):9–14

Pramanik A (2014) Problems and solutions in machining of titanium alloys. Int J Adv Manuf Tech 70(5–8):919–928

Ezugwu EO, Bonney J, Da Silva RB, Cakir O (2007) Surface integrity of finished turned Ti–6Al–4V alloy with PCD tools using conventional and high pressure coolant supplies. Int J Mach Tools and Manuf 47(6):884–891

Hadzley AM, Izamshah R, Sarah AS, Fatin MN (2013) Finite element model of machining with high pressure coolant for Ti-6Al-4V alloy. Procedia Engg 53:624–631

Ayed Y, Germain G, Ammar A, Furet B (2013) Experimental study of tool wear mechanisms in conventional and high pressure coolant assisted machining of titanium alloy Ti17. In Key Engg Mat 554:1961–1966

Ayed Y, Germain G, Ammar A, Furet B (2015) Tool wear analysis and improvement of cutting conditions using the high-pressure water-jet assistance when machining the Ti17 titanium alloy. Precs Engg 42:294–301

Bouchnak TB, Germain G, Morel A, Furet B (2015) Influence of high-pressure coolant assistance on the machinability of the titanium alloy Ti555–3. Mach Sci and Tech 19(1):134–151

Kuram E, Ozcelik B, Bayramoglu M, Demirbas E, Simsek BT (2013) Optimization of cutting fluids and cutting parameters during end milling by using D-optimal design of experiments. J Clean Prod 42:159–166

Iowa Waste Reduction Center (2003) Cutting fluid management for small machining operations—a practical pollution prevention guide. University of Northern Iowa, USA

Shashidhara YM, Jayaram SR (2010) Vegetable oils as a potential cutting fluid—an evolution. Trib Int 43(5):1073–1081

Rao ND, Srikant RR, Rao PN (2007) Effect of emulsifier content on microbial contamination of cutting fluids. Int J Mach and Machinability of Mat 2(3):469–477

Rao PN, Zhang J, Eckman M (2013) Experimental study and regression modeling of tool wear in CNC turning operation using soybean based cutting fluid. J Mech Engg 10(1):85–102

Shokrani C A, Dhokia V, Newman S (2014) Power consumption analysis in the machining of Ti-6Al-4V titanium alloy. In 3rd Annual EPSRC Manuf the Future Conf, University of Bath, UK. Paper ID 45252

Tazehkandi AH, Shabgard M, Kiani G, Pilehvarian F (2016) Investigation of the influences of PCBN tool on the reduction of cutting fluid consumption and increase of machining parameters range in turning Inconel 783 using spray mode of cutting fluid with compressed air. J Clean Prod. doi:10.1016/j.jclepro.2015.12.102

Debnath S, Reddy MM, Yi QS (2014) Environmental friendly cutting fluids and cooling techniques in machining: a review. J Clean Prod 83:33–47

Yang Y, Zhang C, Wang Y, Dai Y, Luo J (2016) Friction and wear performance of titanium alloy against tungsten carbide lubricated with phosphate ester. Trib Int 95:27–34

Prakash D, Ramana M. V (2014) Performance evaluation of different tools in turning of Ti-6Al-4V alloy under different coolant condition. Int J Sci and Res 122–126. Paper ID:ATOM2014_34

Shyha I, Gariani S, Bhatti M (2015) Investigation of cutting tools and working conditions effects when cutting Ti-6al-4V using vegetable oil-based cutting fluids. Procedia Engg 132:577–584

Revankar GD, Shetty R, Rao SS, Gaitonde VN (2014) Analysis of surface roughness and hardness in titanium alloy machining with polycrystalline diamond tool under different lubricating modes. Mat Res 17(4):1010–1022

Liu Z, An Q, Xu J, Chen M, Han S (2013) Wear performance of (nc-AlTiN)/(a-Si 3N 4) coating and (nc-AlCrN)/(a-Si 3N 4) coating in high-speed machining of titanium alloys under dry and minimum quantity lubrication (MQL) conditions. Wear 305(1):249–259

Rahim EA, Sasahara H (2011) A study of the effect of palm oil as MQL lubricant on high speed drilling of titanium alloys. Trib Int 44(3):309–317

Liu Z, Chen M, An Q (2015) Investigation of friction in end-milling of Ti-6Al-4V under different green cutting conditions. Int J Adv Manuf Tech 78(5–8):1181–1192

Rahim EA, Ibrahim MR, Rahim AA, Aziz S, Mohid Z (2015) Experimental investigation of minimum quantity lubrication (MQL) as a sustainable cooling technique. Procedia CIRP 26:351–354

Wakabayashi T, Kuhara J, Atsuta T, Tsukuda A, Sembongi N, Shibata J, Suda S (2015) Near-dry machining of titanium alloy with MQL and hybrid mist supply. Key Engg Mat 656–657:341–346

Lv D, Xu J, Ding W, Fu Y, Yang C, Su H (2016) Tool wear in milling Ti40 burn-resistant titanium alloy using pneumatic mist jet impinging cooling. J Mat Proc Tech 229:641–650

Garcia U, Ribeiro MV (2016) Ti6Al4V titanium alloy end milling with minimum quantity of fluid technique use. Mat and Manuf Proc 31(7):905–918

Hoyne AC, Nath C, Kapoor SG (2015) On cutting temperature measurement during titanium machining with an atomization-based cutting fluid spray system. J Manuf Sci and Engg 137(2):024502

Sun J, Wong YS, Rahman M, Wang ZG, Neo KS, Tan CH, Onozuka H (2006) Effects of coolant supply methods and cutting conditions on tool life in end milling titanium alloy. Mach Sci and Tech 10(3):355–370

Yang Y, Su Y, Li L, He N, Zhao W (2015) Performance of cemented carbide tools with microgrooves in Ti-6Al-4V titanium alloy cutting. Int J Adv Manuf Tech 76(9–12):1731–1738

Bermingham MJ, Sim WM, Kent D, Gardiner S, Dargusch MS (2015) Tool life and wear mechanisms in laser assisted milling Ti–6Al–4V. Wear 322:151–163

Da Silva RB, Vieira JM, Cardoso RN, Carvalho HC, Costa ES, Machado AR, De Ávila RF (2011) Tool wear analysis in milling of medium carbon steel with coated cemented carbide inserts using different machining lubrication/cooling systems. Wear 271(9):2459–2465

Davis B, Schueller JK, Huang Y (2015) Study of ionic liquid as effective additive for minimum quantity lubrication during titanium machining. Manuf Lett 5:1–6

Kolahdouz S, Hadi M, Arezoo B, Zamani S (2015) Investigation of surface integrity in high speed milling of gamma titanium aluminide under dry and minimum quantity lubricant conditions. Procedia CIRP 26:367–372

Banerjee N, Sharma A (2015) Multi-point injection minimum quantity lubrication machining. Materials Science Forum, Trans Tech Publications 830–831:108–111

Sarıkaya M, Güllü A (2015) Multi-response optimization of MQL parameters using Taguchi-based GRA in turning of difficult-to-cut alloy Haynes 25. J Clean Prod 91(15):347–357

Maruda RW, Legutko S, Krolczyk GM, Hloch S, Michalski M (2015) An influence of active additives on the formation of selected indicators of the condition of the X10CrNi18-8 stainless steel surface layer in MQCL conditions. Int J Surf Sci and Engg 9(5):452–465

Mao C, Huang Y, Zhou X, Gan H, Zhang J, Zhou Z (2014) The tribological properties of nanofluid used in minimum quantity lubrication grinding. Int J Adv Manuf Tech 71(5–8):1221–1228

Nguyen TK (2015) Fundamental tool wear study in turning of Ti-6Al-4V alloy (Ti64) and nano-enhanced minimum quantity lubrication (MQL) milling, Doctoral dissertation, Michigan State University, USA

Nguyen T, Nguyen D, Howes P, Kwon P, Park KH (2015) Minimum quantity lubrication (MQL) using vegetable oil with nano-platelet solid lubricant in milling titanium alloy, ASME 2015 Int Manuf Sci and Engg Conf, North Carolina, USA. Paper No. MSEC2015-9466, V002T05A014. doi:10.1115/MSEC2015-9466

Moura RR, Da Silva MB, Machado ÁR, Sales WF (2015) The effect of application of cutting fluid with solid lubricant in suspension during cutting of Ti-6Al-4V alloy. Wear 332:762–771

Setti D, Sinha MK, Ghosh S, Rao PV (2015) Performance evaluation of Ti–6Al–4 V grinding using chip formation and coefficient of friction under the influence of nanofluids. Int J Mach Tools and Manuf 88:237–248

Santosh S, Rajkumar K, Gnanavelbabu A (2015) Effect of hBN solid lubricant concentration on machinability of titanium (Ti-6Al-4V) alloy. Mat Sci Forum 830-831:87–90

Amrita M, Srikant RR, Sitaramaraju AV (2013) Evaluation of cutting fluid with nanoinclusions. J Nanotech Engg and Med 4(3):031007

Duchosal A, Werda S, Serra R, Leroy R, Hamdi H (2015) Numerical modeling and experimental measurement of MQL impingement over an insert in a milling tool with inner channels. Int J Mach Tools and Manuf 94:37–47

Yildiz Y, Nalbant M (2008) A review of cryogenic cooling in machining processes. Int J Mach Tools and Manuf 48(9):947–964

Ghosh S, Rao PV (2015) Application of sustainable techniques in metal cutting for enhanced machinability: a review. J Clean Prod 100:17–34

Schoop J, Ambrosy F, Zanger F, Schulze V, Balk TJ, Jawahir IS (2016) Cryogenic machining of porous tungsten for enhanced surface integrity. J Mat Proc Tech 229:614–621

Maruda RW, Legutko S, Krolczyk GM, Raos P (2015) Influence of cooling conditions on the machining process under MQCL and MQL conditions. Tehnički vjesnik–Technical Gazette 22(4):965–970

Deiab I, Raza SW, Pervaiz S (2014) Analysis of lubrication strategies for sustainable machining during turning of titanium Ti-6Al-4V alloy. Procedia CIRP 17:766–771

Raza SW, Pervaiz S, Deiab I (2014) Tool wear patterns when turning of titanium alloy using sustainable lubrication strategies. Int J Prec Engg and Manuf 15(9):1979–1985

Kaynak Y, Robertson SW, Karaca HE, Jawahir IS (2015) Progressive tool-wear in machining of room-temperature austenitic NiTi alloys: the influence of cooling/lubricating, melting, and heat treatment conditions. J Mat Proc Tech 215:95–104

Abbasi SA, Pingfa F (2015) Evaluating the effectiveness of various coating layers applied on k-grade cemented carbide cutting tools on machinability of titanium alloy Ti-6Al-4V in high speed end milling. In 12th Int Bhurban Conf Appl Sci and Tech (IBCAST), Islamabad, 14–19

Sun Y, Huang B, Puleo DA, Jawahir IS (2015) Enhanced machinability of Ti-5553 alloy from cryogenic machining: comparison with MQL and flood-cooled machining and modeling. Procedia CIRP 31:477–482

Park KH, Yang GD, Suhaimi MA, Lee DY, Kim TG, Kim DW, Lee SW (2015) The effect of cryogenic cooling and minimum quantity lubrication on end milling of titanium alloy Ti-6Al-4V. J Mech Sci and Tech 29(12):5121–5126

Lin H, Wang C, Yuan Y, Chen Z, Wang Q, Xiong W (2015) Tool wear in Ti-6Al-4V alloy turning under oils on water cooling comparing with cryogenic air mixed with minimal quantity lubrication. Int J Adv Manuf Tech 81(1–4):87–101

Maruda RW, Krolczyk GM, Feldshtein E, Pusavec F, Szydlowski M, Legutko S, Sobczak-Kupiec A (2016) A study on droplets sizes, their distribution and heat exchange for minimum quantity cooling lubrication (MQCL). Int J Mach Tools and Manuf 100:81–92

Davoudinejad A, Chiappini E, Tirelli S, Annoni M, Strano M (2015) Finite element simulation and validation of chip formation and cutting forces in dry and cryogenic cutting of Ti–6Al–4V. Procedia Manuf 1:728–739

Strano M, Albertelli P, Chiappini E, Tirelli S (2015) Wear behaviour of PVD coated and cryogenically treated tools for Ti-6Al-4V turning. Int J Matrl Form 8(4):601–611

Thamizhmanii S, Mohideen R, Zaidi AMA, Hasan S (2015) Surface roughness and tool wear on cryogenic treated CBN insert on titanium and Inconel 718 alloy steel. IOP Conf Series: Matrl Sci and Engg 100(1):012058

Bordin A, Bruschi S, Ghiotti A, Bariani PF (2015) Analysis of tool wear in cryogenic machining of additive manufactured Ti6Al4V alloy. Wear 328:89–99

Shokrani CA, Dhokia V, Newman S (2015) Investigation of Cutting parameters in sustainable cryogenic end milling. In 2nd Int Conf Sustain Design and Manuf University of Bath

Lee I, Bajpai V, Moon S, Byun J, Lee Y, Park HW (2015) Tool life improvement in cryogenic cooled milling of the preheated Ti–6Al–4V. Int J Adv Manuf Tech 79(1–4):665–673

Priarone PC, Klocke F, Faga MG, Lung D, Settineri L (2015) Tool life and surface integrity when turning titanium aluminides with PCD tools under conventional wet cutting and cryogenic cooling. Int J Adv Manuf Tech. doi:10.1007/s00170-015-7958-5

Sun S, Brandt M, Palanisamy S, Dargusch MS (2015) Effect of cryogenic compressed air on the evolution of cutting force and tool wear during machining of Ti–6Al–4V alloy. J Matrl Proc Tech 221:243–254

Machai C, Iqbal A, Biermann D, Upmeier T, Schumann S (2013) On the effects of cutting speed and cooling methodologies in grooving operation of various tempers of β-titanium alloy. J Matrl Proc Tech 213(7):1027–1037

Biermann D, Abrahams H, Metzger M (2015) Experimental investigation of tool wear and chip formation in cryogenic machining of titanium alloys. Adv Manuf 3(4):292–299

Ahmed LS, Govindaraju N, Pradeep Kumar M (2016) Experimental investigations on cryogenic cooling in the drilling of titanium alloy. Mat and Manuf Proc 31(5):603–607

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Revuru, R.S., Posinasetti, N.R., VSN, V. et al. Application of cutting fluids in machining of titanium alloys—a review. Int J Adv Manuf Technol 91, 2477–2498 (2017). https://doi.org/10.1007/s00170-016-9883-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9883-7