Abstract

Government legislation and public opinion are the main drivers behind the movement of manufacturing companies towards sustainable production. Fundamentally, companies want to avoid future financial penalties and the industry is therefore under pressure to adapt new techniques and practices in order to become environmentally friendly. The cost efficiency of metal cutting operations is highly dependent on accuracy, excellent surface finish and minimized tool wear and, to this end, has traditionally made abundant use of cutting fluid in machining operations. However, these cutting fluids have been a major contributor to environmental and health issues. In recent years, an enormous effort to eradicate these adverse effects has been made with one important focus being the implementation of minimum quantity lubrication (MQL). In the present work, the authors have reviewed the current state of the art in MQL with a particular focus on drilling, turning, milling and grinding machining operations. Overall, it is concluded that MQL has huge potential as a substitute for conventional flood cooling.

Similar content being viewed by others

References

Amini S, Khakbaz H, Barani A (2015) Improvement of near-dry machining and its effect on tool wear in turning of AISI 4142. Mater Manuf Process 30:241–247

Astakhov V P (2008) “Ecological machining: near-dry machining”, in Machining, ed: Springer London, pp. 195–223

Dureja JS, Singh R, Singh T, Singh P, Dogra M, Bhatti M (2015) Performance evaluation of coated carbide tool in machining of stainless steel (AISI 202) under minimum quantity lubrication (MQL). International Journal of Precision Engineering and Manufacturing-Green Technology 2:123–129

Weck M, Koch A (1993) Spindle bearing systems for high-speed applications in machine tools. CIRP Ann Manuf Technol 42(1):445–448

Brinkmeier E, Brockoff T and Walter A (1997) Minimum quantity lubrication in grinding. In: Proceedings of the 2nd International Machining and Grinding Conference, SME, Dearborn, Michigan, pp MR97–MR230

Brokoff T and Walter A (1998), “Fluid minimization in cutting and grinding”, Abrasives, October, pp. 38–42

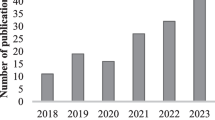

Document search results for “minimum quantity lubrication” (2016), Scopus (www.scopus.com), Elsevier B.V., Amsterdam, The Netherlands (accessed November 16th 2016).

Huber PR and Werner J (1980), “On minimum oil lubrication of roller bearings”, Schmiertechnik + Tribologie, vol. 27, pp. 90–95

Schemmel H (1980), “Minimum quantity oil lubrication of roller bearings”, Schmiertechnik + Tribologie, vol. 27, pp. 193–196

Nakai H, Ino N, Hashimoto H (1996) Piston-ring lubrication problems for refrigeration compressors considering combined effects of supply oil quantity and surface roughness. J Tribol 118:286–291

Sun J, Liu GS, Xu F, Miao EM, Song XH, Shu L et al (2015) Effect of the lubrication condition at entrance on the lubrication performance of piston ring-cylinder liner frictional pair. Mocaxue Xuebao/Tribology 35:423–430

Brinksmeier E, Walter A, Jansson R, Diersen P (1999) Aspects of cooling lubrication reduction in machining advanced materials. Proc Inst Mech Eng B J Eng Manuf 213(8):769–778

Barczak LM, Batako ADL, Morgan MN (2010) A study of plane surface grinding under minimum quantity lubrication (MQL) conditions. Int J Mach Tools Manuf 50:977–985

Bhowmick S (2011), “Minimum quantity lubrication machining of aluminum and magnesium alloys”, NR61929 Ph.D., University of Windsor (Canada), Ann Arbor

Morgan MN, Barczak L, Batako A (2012) Temperatures in fine grinding with minimum quantity lubrication (MQL). Int J Adv Manuf Technol 60:951–958

Tschätsch H and Reichelt A (2009), “Cutting fluids (coolants and lubricants)”, in Applied machining technology, ed: Springer Berlin Heidelberg, pp. 349–352

Obikawa T, Kamata Y, Asano Y, Nakayama K, Otieno AW (2008) Micro-liter lubrication machining of Inconel 718. Int J Mach Tools Manuf 48:1605–1612

Sharma VS, Dogra M, Suri NM (2009) Cooling techniques for improved productivity in turning. Int J Mach Tools Manuf 49:435–453

Tai BL, Stephenson DA, Furness RJ, Shih AJ (2014) Minimum quantity lubrication (MQL) in automotive powertrain machining. Procedia CIRP 14:523–528

Rahman M, Kumar AS and Manzoor-Ul-Salam (2001) Evaluation of minimal of lubricant in end milling. Int J Adv Manuf Technol 18(4):235–241

Mao C, Huang Y, Zhou X, Gan H, Zhang J, Zhou Z (2014) The tribological properties of nanofluid used in minimum quantity lubrication grinding. Int J Adv Manuf Technol 71:1221–1228

Uysal A, Demiren F, Altan E (2015) Applying minimum quantity lubrication (MQL) method on milling of martensitic stainless steel by using nano Mos2 reinforced vegetable cutting fluid. Procedia - Social and Behavioral Sciences 195:2742–2747

Salaam H, Taha ZB, Shah TMY, Ya T (Nov 2012) Minimum quantity lubrication (MQL) using Ranque-Hilsch vortex tube (RHVT) for sustainable machining. Appl Mech Mater 217-219:2012

Rao DN, Srikant RR, Krishna PV and Subrahmanyam MS (2008), “Nano cutting fluids in minimum quantity lubrication”, in Proceedings of the International Multi-Conference on Engineering and Technological Innovation (IMETI), vol. 1, pp. 60–63, Orlando, U.S.A

Narutaki N, Yamane Y, Tashima S, Kuroki H (1997) A new advanced ceramic for dry machining. Annals of the CIRP 16(1):43–48

Granger C (1994) Dry machining’s double benefit. Machinery and Production Engineering 152:14–20

Feng SC, Hattori M (2000) Cost and process information modeling for dry machining. Proceedings of the International Workshops for Environment Conscious Machining - ICEM 2000:7

Boubekri N, Shaikh V, Foster PR (2010) A technology enabler for green machining: minimum quantity lubrication (MQL). J Manuf Technol Manag 21:556–566

Klocke F, Eisenblätter G (1997) Dry cutting. CIRP Ann Manuf Technol 46:519–526

Hinduja S (2004), Proceedings of the 34th International MATADOR Conference: Formerly The International Machine Tool Design and Research Conferences: Springer London

Freiler C, Hörner D, Buss W, Kubicki F, LoscA, and Mang T (2000), “Lubricants, 7. Metalworking fluids and forming lubricants”, in Ullmann’s encyclopedia of industrial chemistry, ed: Wiley-VCH Verlag GmbH & Co. KGaA

Landgraf G. (2004, January 2004) Dry goods. cutting tool engineering. 4. Available: http://unist.com/pdfs/articles/Dry_Goods.pdf

Stephenson DA and Agapiou JS (2016), p. 947 in Metal cutting theory practice (3rd edition), CRC press

Sreejith PS, Ngoi BKA (2000) Dry machining: machining of the future. J Mater Process Technol 101:287–291

Islam MN and Boswell B (2011), “An investigation of surface finish in dry turning”, in Proceedings of the World Congress on Engineering, pp. 6–8

Dudzinski D, Devillez A, Moufki A, Larrouquère D, Zerrouki V, Vigneau J (2004) A review of developments towards dry and high speed machining of Inconel 718 alloy. Int J Mach Tools Manuf 44:439–456

Kutz M (ed) (2007) Environmentally Conscious Manufacturing, John Wiley & Sons, Inc., Hoboken

Dasch JM, Ang CC, Wong CA, Cheng YT, Weiner AM, Lev LC et al (2006) A comparison of five categories of carbon-based tool coatings for dry drilling of aluminum. Surf Coat Technol 200:2970–2977

Hadad M, Hadi M (2013) An investigation on surface grinding of hardened stainless steel S34700 and aluminum alloy AA6061 using minimum quantity of lubrication (MQL) technique. Int J Adv Manuf Technol 68:2145–2158

Dixit US, Sarma DK, and Davim JP (2012), “Machining with minimal cutting fluid”, in Environmentally friendly machining, ed: Springer US, pp. 9–17.

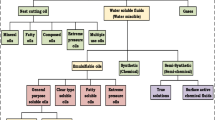

Debnath S, Reddy MM, Yi QS (2014) Environmental friendly cutting fluids and cooling techniques in machining: a review. J Clean Prod 83:33–47

Khan MMA, Dhar NR (2006) Performance evaluation of minimum quantity lubrication by vegetable oil in terms of cutting force, cutting zone temperature, tool wear, job dimension and surface finish in turning AISI-1060 steel. Journal of Zhejiang University SCIENCE A 7:1790–1799

Sales W, Becker M, Barcellos CS, Jr JL, Bonney J, Ezugwu EO (2009) Tribological behaviour when face milling AISI 4140 steel with minimum quantity fluid application. Industrial Lubrication and Tribology 61:84–90

E. A. Rahim and H. Sasahara (2010), “High speed MQL drilling of titanium alloy using synthetic ester and palm oil”, in Proceedings of the 36th International MATADOR Conference, S. Hinduja and L. Li, Eds., ed: Springer London, pp. 193–196

Belluco W, De Chiffre L (2004) Performance evaluation of vegetable-based oils in drilling austenitic stainless steel. J Mater Process Technol 148:171–176

Ginting YR, Boswell B, Biswas W, Islam N (2015) Advancing environmentally conscious machining. Procedia CIRP 26:391–396

Islam MN (2013) Effect of additional factors on dimensional accuracy and surface finish of turned parts. Mach Sci Technol 17:145–162

Ramana MV, Rao GKM, and Rao DH (2011) “Experimental investigations and selection of optimal cutting conditions in turning of Ti-6Al-4V alloy with different cutting fluids by minimum quantity lubrication (MQL) methodology”, i-Manager’s Journal on Mechanical Engineering, vol. 2, pp. 45–52

Tasdelen B, Wikblom T, Ekered S (2008) Studies on minimum quantity lubrication (MQL) and air cooling at drilling. J Mater Process Technol 200:339–346

Braghini Junior A, Diniz A, Filho F (2009) Tool wear and tool life in end milling of 15–5 PH stainless steel under different cooling and lubrication conditions. Int J Adv Manuf Technol 43:756–764

Su Y, He N, Li L (2010) Effect of cryogenic minimum quantity lubrication (CMQL) on cutting temperature and tool wear in high-speed end milling of titanium alloys. Appl Mech Mater 34-35:1816

Kurgin S, Dasch JM, Simon DL, Barber GC, Zou Q (2014) A comparison of two minimum quantity lubrication delivery systems. Industrial Lubrication and Tribology 66:151–159

Zeilmann RP, Weingaertner WL (2006) Analysis of temperature during drilling of Ti6Al4V with minimal quantity of lubricant. J Mater Process Technol 179:124–127

Brinksmeier E, Janssen R (2002) Drilling of multi-layer composite materials consisting of carbon fiber reinforced plastics (CFRP), titanium and aluminum alloys. CIRP Ann Manuf Technol 51:87–90

Brinksmeier E, Pecat O and Rentsch R (2015) Quantitative analysis of chip extraction in drilling of Ti6Al4V. CIRP Ann Manuf Technol 64(1):93–96

Sreejith PS (2008) Machining of 6061 aluminium alloy with MQL, dry and flooded lubricant conditions. Mater Lett 62:276–278

Yoshimura H, Moriwaki T, Ohmae N, Nakai T, Shibasaka T, Kinoshita H et al (2006) Study on near dry machining of aluminum alloys. JSME Int J Ser C Mech Syst Mach Elem Manuf 49:83–89

Yan J, Murakami Y, and Davim JP (2009) “Tool design, tool wear and tool life”, in Machining Dynamics, K. Cheng, Ed., ed: Springer London, pp. 117–149

Tsao CC (2007) An experiment study of hard coating and cutting fluid effect in milling aluminum alloy. Int J Adv Manuf Technol 32:885–891

de Lacalle LNL, Lamikiz A, Sanchez JA, Cabanes I (2001) Cutting conditions and tool optimization in the high-speed milling of aluminium alloys. Proceedings of the Institution of Mechanical Engineers 215:1257

Diciuc V, Lobontiu M, Bran G, Lazar V (2013) The influence of the lubrication method and the cutting regime on the surface roughness when milling 7175 aluminum alloy. Appl Mech Mater 371:28

Sohrabpoor H, Khanghah S, Teimouri R (2015) Investigation of lubricant condition and machining parameters while turning of AISI 4340. Int J Adv Manuf Technol 76:2099–2116

Dhar NR, Islam MW, Islam S, Mithu MAH (2006) The influence of minimum quantity of lubrication (MQL) on cutting temperature, chip and dimensional accuracy in turning AISI-1040 steel. J Mater Process Technol 171:93–99

Dhar NR, Ahmed MT, Islam S (2007) An experimental investigation on effect of minimum quantity lubrication in machining AISI 1040 steel. Int J Mach Tools Manuf 47:748–753

Dhar NR, Kamruzzaman M, Ahmed M (2006) Effect of minimum quantity lubrication (MQL) on tool wear and surface roughness in turning AISI-4340 steel. J Mater Process Technol 172:299–304

Rahman M, Senthil Kumar A, Salam MU (2002) Experimental evaluation on the effect of minimal quantities of lubricant in milling. Int J Mach Tools Manuf 42:539–547

da Silva LC, da Mota PR, da Silva MB, Ezugwu EO, Machado ÁR (2015) Study of burr behavior in face milling of PH 13-8 Mo stainless steel. CIRP J Manuf Sci Technol 8:34–42

Priarone PC, Robiglio M, Settineri L, Tebaldo V (2014) Milling and turning of titanium aluminides by using minimum quantity lubrication. Procedia CIRP 24:62–67

Aryasomayajula A, U. o. Arkansas (2008) Low temperature alpha alumina thin film coating for cutting tool application by AC inverted magnetron sputtering technique. University of Arkansas

Graham D (2002) Turning difficult-to-machine alloys. Modern Machine Shop 75:92

Lorincz J (2015) The heat is on difficult-to-machine metals. Manuf Eng 154:55–64

Pramanik A, Littlefair G (2015) Machining of titanium alloy (Ti-6Al-4V)-theory to application. Mach Sci Technol 19:1–49

Park K-H, Yang G-D, Lee M-G, Jeong H, Lee S-W, Lee D (2014) Eco-friendly face milling of titanium alloy. Int J Precis Eng Manuf 15:1159–1164

Wang ZG, Rahman M, Wong YS, Neo KS, Sun J, Tan CH et al (2009) Study on orthogonal turning of titanium alloys with different coolant supply strategies. Int J Adv Manuf Technol 42:621–632

Boswell B, Islam MN (2016) Sustainable cooling method for machining titanium alloy. IOP Conference Series: Materials Science and Engineering 114:012021

Kaynak Y, Lu T, Jawahir IS (2014) Cryogenic machining-induced surface integrity: a review and comparison with dry, MQL, and flood-cooled machining. Mach Sci Technol 18:149–198

(2014, May 13). MONEL alloy K-500 marine alloy QQ-N-286(UNS N05500) Ni 65.5 Cu 29.5 Al 2.7, Ti 0.6 description [Online]. Available: http://www.hpalloy.com/Alloys/descriptions/MONELK_500.aspx

Javam N (2013) The study of high speed turning using MQL. Indian Journal of Science and Technology 6:4123–4127

Sharma J, Sidhu BS (2014) Investigation of effects of dry and near dry machining on AISI D2 steel using vegetable oil. J Clean Prod 66:619–623

Beno T, Isaksson M, Pejryd L (2007) Investigation of minimal quantity lubrication in turning of Waspaloy. In: Takata S, Umeda Y (eds) Advances in life cycle engineering for sustainable manufacturing businesses. Springer, London, pp 305–310

Park KH, Suhaimi MA, Yang GD, Lee DY, Lee SW, Kwon P (2017) Milling of titanium alloy with cryogenic cooling and minimum quantity lubrication (MQL). Int J Precis Eng Manuf 18:5–14

Thamizhmanii RSHS (2009) A study of minimum quantity lubrication on Inconel 718 steel. International Scientific Journal 39:38–44

Biermann D, Iovkov I (2015) Investigations on the thermal workpiece distortion in MQL deep hole drilling of an aluminium cast alloy. CIRP Annals-Manufacturing Technology 64:85–88

Bhowmick S, Alpas AT (2008) Minimum quantity lubrication drilling of aluminium–silicon alloys in water using diamond-like carbon coated drills. Int J Mach Tools Manuf 48:1429–1443

Fox-Rabinovich G, Dasch JM, Wagg T, Yamamoto K, Veldhuis S, Dosbaeva GK et al (2011) Cutting performance of different coatings during minimum quantity lubrication drilling of aluminum silicon B319 cast alloy. Surf Coat Technol 205:4107–4116

Davim JP, Sreejith PS, Gomes R, Peixoto C (2006) Experimental studies on drilling of aluminium (AA1050) under dry, minimum quantity of lubricant, and flood-lubricated conditions. Proceedings of the Institution of Mechanical Engineers B, Journal of Engineering Manufacture 220:1605–1611

Braga DU, Diniz AE, Miranda GWA, Coppini NL (2002) Using a minimum quantity of lubricant (MQL) and a diamond coated tool in the drilling of aluminum–silicon alloys. J Mater Process Technol 122:127–138

Shingarwade RU, Chavan PS (2014) A review on MQL in reaming. International Journal of Mechanical Engineering and Robotics Research 3:392–398

Zeilmann R, Nicola G, Vacaro T, Teixeira C, Heiler R (2012) Implications of the reduction of cutting fluid in drilling AISI P20 steel with carbide tools. Int J Adv Manuf Technol 58:431–441

Heinemann R, Hinduja S, Barrow G, Petuelli G (2006) Effect of MQL on the tool life of small twist drills in deep-hole drilling. Int J Mach Tools Manuf 46:1–6

Meena A, El Mansori M (2011) Study of dry and minimum quantity lubrication drilling of novel austempered ductile iron (ADI) for automotive applications. Wear 271:2412–2416

Brinksmeier E, Pecat O, Rentsch R (2015) Quantitative analysis of chip extraction in drilling of Ti 6 Al 4 V. CIRP Annals-Manufacturing Technology 64:93–96

Di Ilio A, Paoletti A, Tagliaferri V, Veniali F (1996) An experimental study on grinding of silicon carbide reinforced aluminium alloys. Int J Mach Tools Manuf 36:673–685

J. R. Davis, J. R. D. Associates, and A. S. M. I. H (1993) Committee, aluminum and aluminum alloys: ASM International

Islam MN, Pramanik A, Basak A, and Littlefair G (2013) “Machining and tool wear mechanisms during machining titanium alloys”

Yuan SX, Bi B (2009) Experimental study on the belt grinding mechanism for aluminum alloys. Appl Mech Mater 16-19:60

Hadad M, Sadeghi B (2012) Thermal analysis of minimum quantity lubrication-MQL grinding process. Int J Mach Tools Manuf 63:1–15

Shao Y, Fergani O, Li B, Liang S (2015) Residual stress modeling in minimum quantity lubrication grinding. Int J Adv Manuf Technol:1–9

Mao C, Tang X, Zou H, Zhou Z, Yin W (2012) Experimental investigation of surface quality for minimum quantity oil–water lubrication grinding. Int J Adv Manuf Technol 59:93–100

Hadad MJ, Tawakoli T, Sadeghi MH, Sadeghi B (2012) Temperature and energy partition in minimum quantity lubrication-MQL grinding process. Int J Mach Tools Manuf 54–55:10–17

Hogan BJ (2011) Grinding difficult materials. Manuf Eng 146(2):71–77

Sadeghi MH, Haddad MJ, Tawakoli T, Emami M (2009) Minimal quantity lubrication-MQL in grinding of Ti–6Al–4V titanium alloy. Int J Adv Manuf Technol 44:487–500

Setti D, Ghosh S, and Rao PV (2012) “Application of nano cutting fluid under minimum quantity lubrication (MQL) technique to improve grinding of Ti - 6Al - 4V alloy”, Çanakkale, pp. 512–516

An Q, Fu Y, Xu J (2010) A new technology on enhancing heat transfer during grinding of titanium alloy. Industrial Lubrication and Tribology 62:168–173

Maruda RW, Krolczyk GM, Feldshtein E, Pusavec F, Szydlowski M, Legutko S, Sobczak-Kupiec A (2016) A study on droplets sizes, their distribution and heat exchange for minimum quantity cooling lubrication (MQCL). Int J Mach Tools Manuf 100:81–92

Gupta M, Singh G, Sood P (2015) Experimental investigation of machining AISI 1040 medium carbon steel under cryogenic machining: a comparison with dry machining. Journal of The Institution of Engineers (India): Series C 96:373–379

H. Tönshoff and B. Denkena, “Cooling lubrication”, in Basics of cutting and abrasive processes, ed: Springer Berlin Heidelberg, 2013, pp. 371–396.

Kalita P, Malshe AP, Arun Kumar S, Yoganath VG, Gurumurthy T (2012) Study of specific energy and friction coefficient in minimum quantity lubrication grinding using oil-based nanolubricants. J Manuf Process 14:160–166

Kalita P, Malshe AP, Rajurkar KP (2012) Study of tribo-chemical lubricant film formation during application of nanolubricants in minimum quantity lubrication (MQL) grinding. CIRP Ann Manuf Technol 61:327–330

Davis B, Schueller JK, Huang Y (2015) Study of ionic liquid as effective additive for minimum quantity lubrication during titanium machining. Manufacturing Letters 5:1–6

Goindi GS, Chavan SN, Mandal D, Sarkar P, Jayal AD (2015) Investigation of ionic liquids as novel metalworking fluids during minimum quantity lubrication machining of a plain carbon steel. Procedia CIRP 26:341–345

Pham M-Q, Yoon H-S, Khare V, Ahn S-H (2014) Evaluation of ionic liquids as lubricants in micro milling—process capability and sustainability. J Clean Prod 76:167–173

Krajnik P, Pusavec F, Rashid A (2011) Nanofluids: properties, applications and sustainability aspects in materials processing technologies. In: Seliger G, Khraisheh MMK, Jawahir IS (eds) Advances in sustainable manufacturing. Springer, Berlin Heidelberg, pp 107–113

Zhang D, Li C, Zhang Y, Jia D, Zhang X (2015) Experimental research on the energy ratio coefficient and specific grinding energy in nanoparticle jet MQL grinding. Int J Adv Manuf Technol 78:1275–1288

Hemmat Esfe M, Karimipour A, Yan W-M, Akbari M, Safaei MR, Dahari M (2015) Experimental study on thermal conductivity of ethylene glycol based nanofluids containing Al2O3 nanoparticles. Int J Heat Mass Transf 88:728–734

Fedele L, Colla L, Bobbo S (2012) Viscosity and thermal conductivity measurements of water-based nanofluids containing titanium oxide nanoparticles. Int J Refrig 35:1359–1366

Arulprakasajothi M, Elangovan K, Reddy KH, Suresh S (2015) Heat transfer study of water-based nanofluids containing titanium oxide nanoparticles. Materials Today: Proceedings 2:3648–3655

Li X, Zou C, Lei X, Li W (2015) Stability and enhanced thermal conductivity of ethylene glycol-based SiC nanofluids. Int J Heat Mass Transf 89:613–619

Karimi A, Sadatlu MAA, Saberi B, Shariatmadar H and Ashjaee M (2015) Experimental investigation on thermal conductivity of water based nickel ferrite nanofluids. Adv Powder Technol 26(6):1529–1536

Yu W, Xie H, Li Y, Chen L, Wang Q (2011) Experimental investigation on the thermal transport properties of ethylene glycol based nanofluids containing low volume concentration diamond nanoparticles. Colloids Surf A Physicochem Eng Asp 380:1–5

Peng DX, Kang Y, Hwang RM, Shyr SS, Chang YP (2009) Tribological properties of diamond and SiO2 nanoparticles added in paraffin. Tribol Int 42:911–917

Tang Z, Li S (2014) A review of recent developments of friction modifiers for liquid lubricants (2007–present). Curr Opinion Solid State Mater Sci 18:119–139

Sharma AK, Tiwari AK, Dixit AR (2015) Mechanism of nanoparticles functioning and effects in machining processes: a review. Materials Today: Proceedings 2:3539–3544

Xie H, Jiang B, He J, Xia X and Pan F (2016) Lubrication performance of MoS2 and SiO2 nanoparticles as lubricant additives in magnesium alloy-steel contacts. Tribol Int 93:63–70

Jiao D, Zheng S, Wang Y, Guan R, Cao B (2011) The tribology properties of alumina/silica composite nanoparticles as lubricant additives. Appl Surf Sci 257:5720–5725

Peña-Parás L, Taha-Tijerina J, Garza L, Maldonado-Cortés D, Michalczewski R, Lapray C (2015) Effect of CuO and Al2O3 nanoparticle additives on the tribological behavior of fully formulated oils. Wear 332–333:1256–1261

Su Y, Gong L, Li B, Liu Z, Chen D (2015) Performance evaluation of nanofluid MQL with vegetable-based oil and ester oil as base fluids in turning. Int J Adv Manuf Technol:1–7

Rahmati B, Sarhan AAD, Sayuti M (2014) Morphology of surface generated by end milling AL6061-T6 using molybdenum disulfide (MoS2) nanolubrication in end milling machining. J Clean Prod 66:685–691

Zhang Y, Li C, Jia D, Zhang D, Zhang X (2015) Experimental evaluation of the lubrication performance of MoS2/CNT nanofluid for minimal quantity lubrication in Ni-based alloy grinding. Int J Mach Tools Manuf 99:19–33

Buzea C, Pacheco I, Robbie K (2007) Nanomaterials and nanoparticles: sources and toxicity. Biointerphases 2:MR17–MR71

Elsaesser A, Howard CV (2012) Toxicology of nanoparticles. Adv Drug Deliv Rev 64:129–137

Chaturvedi DA, Jain DP, and Malik DS (2012) “Study of nano technology based solid lubricant”, vol. 3, pp. 31–32

“Nanotechnology Work Health & Safety (2013)”, E. Australia, Ed., ed. Australia

Seyedmahmoudi SH, Harper S, Weismiller M, Haapala K (2015) Evaluating the use of zinc oxide and titanium dioxide nanoparticles in a metalworking fluid from a toxicological perspective. J Nanopart Res 17:1–12

Kamimura H, Kubo T, Minami I, Mori S (2007) Effect and mechanism of additives for ionic liquids as new lubricants. Tribol Int 40:620–625

Cai M, Zhao Z, Liang Y, Zhou F, Liu W (2010) Alkyl imidazolium ionic liquids as friction reduction and anti-wear additive in polyurea grease for steel/steel contacts. Tribol Lett 40:215–224

Battez AH, González R, Viesca JL, Blanco D, Asedegbega E, Osorio A (2009) Tribological behaviour of two imidazolium ionic liquids as lubricant additives for steel/steel contacts. Wear 266:1224–1228

Jiménez AE, Bermúdez MD, Carrión FJ, Martínez-Nicolás G (2006) Room temperature ionic liquids as lubricant additives in steel–aluminium contacts: influence of sliding velocity, normal load and temperature. Wear 261:347–359

Jiménez A-E, Bermúdez M-D (2008) Imidazolium ionic liquids as additives of the synthetic ester propylene glycol dioleate in aluminium–steel lubrication. Wear 265:787–798

Han Y, Qiao D, Zhang L, Feng D (2015) Study of tribological performance and mechanism of phosphonate ionic liquids for steel/aluminum contact. Tribol Int 84:71–80

Jiménez A, Bermúdez M-D (2009) Ionic liquids as lubricants of titanium–steel contact. Tribol Lett 33:111–126

Jiménez AE, Bermúdez MD (2010) Ionic liquids as lubricants of titanium–steel contact. Part 2: friction, wear and surface interactions at high temperature. Tribol Lett 37:431–443

Libardi A, Schmid SR, Sen M, Schneider W (2013) Evaluation of ionic fluids as lubricants in manufacturing. J Manuf Process 15:414–418

Keskin S, Kayrak-Talay D, Akman U, Hortaçsu Ö (2007) A review of ionic liquids towards supercritical fluid applications. J Supercrit Fluids 43:150–180

Frade RFM, Afonso CAM (2010) Impact of ionic liquids in environment and humans: an overview. Hum Exp Toxicol 29:1038–1054

Mulkiewicz E, Stepnowski P (2014) Recent developments in ionic liquid toxicity assessment. International Journal of Cognitive Linguistics 13:391–428

Stepnowski P, Skladanowski AC, Ludwiczak A, Laczynska E (2004) Evaluating the cytotoxicity of ionic liquids using human cell line HeLa. Hum Exp Toxicol 23:513–517

Ranke J, Stolte S, Stormann R, Arning J, Jastorff B (2007) Design of sustainable chemical products—the example of ionic liquids. Chem Rev 107:2183–2206

Kulacki KJ (2009), “Proactive aquatic ecotoxicology: a hazard assessment of room-temperature ionic liquids”, 3436462 Ph.D., University of Notre Dame, Ann Arbor

Heisel U, Schaal M, Wolf G (2010) Influence of minimum quantity lubrication on burr formation in milling. In: Aurich JC, Dornfeld D (eds) Burrs - analysis, control and removal. Springer, Berlin Heidelberg, pp 139–146

Faverjon P, Rech J, Valiorgue F, Orset M (2015) Optimization of a drilling sequence under MQL to minimize the thermal distortion of a complex aluminum part. Prod Eng 9:505–515

Stephenson DA, Skerlos SJ, King AS, Supekar SD (2014) Rough turning Inconel 750 with supercritical CO2-based minimum quantity lubrication. J Mater Process Technol 214:673–680

Boswell B and Islam MN (2013) The challenge of adopting minimal quantities of lubrication for end milling aluminium. In: Yang G-C, Ao S-1, Gelman L (eds) IAENG transactions on engineering technologies, vol 229. Springer, Dordrecht, pp 713–724

Duchosal A, Werda S, Serra R, Leroy R, Hamdi H (2015) Numerical modeling and experimental measurement of MQL impingement over an insert in a milling tool with inner channels. Int J Mach Tools Manuf 94:37–47

Kırmacı V (2009) Exergy analysis and performance of a counter flow Ranque–Hilsch vortex tube having various nozzle numbers at different inlet pressures of oxygen and air. Int J Refrig 32:1626–1633

Dutta T, Sinhamahapatra KP, Bandyopdhyay SS (2010) Comparison of different turbulence models in predicting the temperature separation in a Ranque–Hilsch vortex tube. Int J Refrig 33:783–792

Selek M, Tasdemir S, Dincer K, Baskaya S (2011) Experimental examination of the cooling performance of Ranque-Hilsch vortex tube on the cutting tool nose point of the turret lathe through infrared thermography method. Int J Refrig 34:807–815

Mohamad A, Amin NAM, Razlan ZM, Majid MSA (2013) Experimental studies of a Ranque-Hilsch vortex tube. Appl Mech Mater 390:670

Dincer K, Tasdemir S, Baskaya S, Uysal BZ (2008) Modeling of the effects of length to diameter ratio and nozzle number on the performance of counterflow Ranque–Hilsch vortex tubes using artificial neural networks. Appl Therm Eng 28:2380–2390

Agrawal N, Naik SS, and Gawale YP (2014), “Experimental investigation of vortex tube using natural substances”, International Communications in Heat and Mass Transfer, vol. 52, pp. 51–55, 3//

Yalçın B, Özgür AE, Koru M (2009) The effects of various cooling strategies on surface roughness and tool wear during soft materials milling. Mater Des 30:896–899

Liu J, Kevin Chou Y (2007) On temperatures and tool wear in machining hypereutectic Al–Si alloys with vortex-tube cooling. Int J Mach Tools Manuf 47:635–645

Balmer RT (1988) Pressure-driven Ranque-Hilsch temperature separation in liquids. J Fluids Eng 110:161–164

Chowdhury SA, Islam MN and Boswell B (2015) Predicting the influence of the machining parameters on the tool tip temperature. In: Yang G-C, Ao S-I, Gelman L (eds) Transactions on engineering technologies. Springer, Dordrecht, pp 305–316

Zhang S, Li J, Lv H (2014) Tool wear and formation mechanism of white layer when hard milling H13 steel under different cooling/lubrication conditions. Advances in Mechanical Engineering

Su Y, He N, Li L, Iqbal A, Xiao MH, Xu S et al (2007) Refrigerated cooling air cutting of difficult-to-cut materials. Int J Mach Tools Manuf 47:927–933

Ravi S, Pradeep Kumar M (2011) Experimental investigations on cryogenic cooling by liquid nitrogen in the end milling of hardened steel. Cryogenics 51:509–515

Huang X, Zhang X, Mou H, Zhang X, Ding H (2014) The influence of cryogenic cooling on milling stability. J Mater Process Technol 214:3169–3178

Dhar NR, Nanda Kishore SV, Paul S, Chattopadhyay AB (2002) The effects of cryogenic cooling on chips and cutting forces in turning AISI 1040 and AISI 4320 steels. Proceedings of the Institution of Mechanical Engineers 216:713

Venugopal KA, Tawade R, Prashanth PG, Paul S, Chattopadhyay AB (2003) Turning of titanium alloy with TiB2-coated carbides under cryogenic cooling. Proceedings of the Institution of Mechanical Engineers 217:1697–1707

Dix M, Wertheim R, Schmidt G, Hochmuth C (2014) Modeling of drilling assisted by cryogenic cooling for higher efficiency. CIRP Ann Manuf Technol 63:73–76

Manimaran G, Pradeep Kumar M, Venkatasamy R (2014) Influence of cryogenic cooling on surface grinding of stainless steel 316. Cryogenics 59:76–83

Yuan SM, Yan LT, Liu WD, Liu Q (2011) Effects of cooling air temperature on cryogenic machining of Ti–6Al–4V alloy. J Mater Process Technol 211:356–362

Zou LT, Zhang S, Zhang Q (2012) Computer fluid dynamics analysis of cryogenic oil mist and structural optimization of spraying nozzle. Appl Mech Mater 241-244:1310

Sanchez JA, Pombo I, Alberdi R, Izquierdo B, Ortega N, Plaza S et al (2010) Machining evaluation of a hybrid MQL-CO2 grinding technology. J Clean Prod 18:1840–1849

García E, Méresse D, Pombo I, Dubar M, Sánchez JA (2015) Role of frozen lubricant film on tribological behaviour and wear mechanisms in grinding. Int J Adv Manuf Technol:1–11

Clarens AF, Hayes KF, Skerlos SJ (2006) Feasibility of metalworking fluids delivered in supercritical carbon dioxide. J Manuf Process 8:47–53

“Greenhouse Gases” 2008, P. o. Australia, Ed., ed. Australua

Mon TT, Ramli J, Jeefferie AR, Sharif S, Venkatesh VC (2011) Performance of cryogenic machining with nitrogen gas in machining of titanium. Appl Mech Mater 52-54:2003

Lozowski D (2010) Supercritical CO2: a green solvent. Chem Eng 117:15–18

Supekar SD, Clarens AF, Stephenson DA, Skerlos SJ (2012) Performance of supercritical carbon dioxide sprays as coolants and lubricants in representative metalworking operations. J Mater Process Technol 212:2652–2658

Ekvall T, Weidema B (2004) System boundaries and input data in consequential life cycle inventory analysis. Int J Life Cycle Assess 9:161–171

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boswell, B., Islam, M., Davies, I.J. et al. A review identifying the effectiveness of minimum quantity lubrication (MQL) during conventional machining. Int J Adv Manuf Technol 92, 321–340 (2017). https://doi.org/10.1007/s00170-017-0142-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0142-3