Abstract

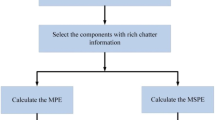

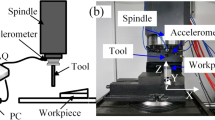

Chatter is a kind of self-excited unstable vibration during machining process, which always leads to multiple negative effects such as poor surface quality, dimension accuracy error, excessive noise, and tool wear. For purposes of monitoring the processing state of milling process and detecting chatter timely, a novel online chatter detection method was proposed. In the proposed method, the acceleration signals acquired by sensor were decomposed into a series of intrinsic mode functions (IMFs) by the adaptive analysis method named ensemble empirical mode decomposition (EEMD), and the IMFs which contain the feature information of milling process were selected as the analyzed signals. The two indicators power spectral entropy and fractal dimension which is obtained by morphological covering method are introduced to detect the chatter features. Then, both the frequency characteristic and morphological feature of the extracted signals can be reflected by the two indicators. To verify the approach, milling experiments were performed; the experiment results show that the proposed method can detect chatter timely and effectively, which is important in the aspect of improving the milling quality. And finally, in order to detect milling chatter timely, an online milling chatter monitoring system was developed.

Similar content being viewed by others

Change history

20 October 2020

The original version of this article contained mistakes.

Reference

Wiercigroch M, Krivtsov AM (2001) Frictional chatter in orthogonal metal cutting. Philosophical Transactions: Mathematical Physical and Engineering Sciences (Series A) 359(1781):713–738. doi:10.1098/rsta.2000.0752

Wiercigroch M, Budak E (2001) Sources of nonlinearities, chatter generation and suppression in metal cutting. Philosophical Transactions of the Royal Society London 359(1781):663–693. doi:10.1098/rsta.2000.0750

Tlusty J, Polacek M (1963) The stability of machine tools against self-excited vibrations in machining, international research in production engineering. Mach Sci and Technol 465–474

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tools Manuf 51(5):363–376. doi:10.1016/j.ijmachtools.2011.01.001

Altintas Y, Budak E (1995) Analytical prediction of stability lobes in milling. CIRP Ann Manuf Technol 44(1):357–362

Altintas Y (2012) Manufacturing automation: metal cutting mechanics, machine tool vibrations, and CNC design. Cambridge University Press, Cambridge

Gradisek J, Kalveram M, Insperger T, Weinert K, Stepan G, Govekar E, Grabec I (2005) On stability prediction for milling. Int J Mach Tools Manuf 45(7–8):769–781. doi:10.1016/j.ijmachtools.2004.11.015

Mann BP, Young KA, Schmitz TL, Dilley DN (2005) Simultaneous stability and surface location error predictions in milling. J Manuf Sci E-T ASME 127(3):446–453. doi:10.1115/1.1948394

Minis I, Yanushevsky R (1993) A new theoretical approach for the prediction of machine tool chatter in milling. J Eng Ind-Trans ASME 115(1):1–8. doi:10.1115/1.2901633

Budak E, Altintas Y (1998) Analytical prediction of chatter stability in milling—part I: general formulation. ASME J Dyn Syst Meas Control 120(1):22–30. doi:10.1115/1.2801317

Merdol SD, Altintas Y (2004) Multi frequency solution of chatter stability for low immersion milling. J Manuf Sci Eng.-Trans ASME 126(3):459–466. doi:10.1115/1.1765139

Altintas Y, Engin S, Budak E (1999) Analytical stability prediction and design of variable pitch cutters. J Manuf Sci Eng-Trans ASME 121(2):173–178. doi:10.1115/1.2831201

Altintas Y (2001) Analytical prediction of three dimensional chatter stability in milling. JSME Int J Ser C 44(3):717–723

Butcher EA, Ma HT, Bueler E, Averina V, Szabo Z (2004) Stability of linear time-periodic delay-differential equations via Chebyshev polynomials. Int J Numer Methods Eng 59(7):895–922. doi:10.1002/nme.894

Butcher EA, Bobrenkov OA, Bueler E, Nindujarla P (2009) Analysis of milling stability by the Chebyshev collocation method: algorithm and optimal stable immersion levels. J Comput Nonlinear Dyn 4(3):031003:1–03100312. doi:10.1115/1.3124088

Khasawneh FA, Bobrenkov OA, Mann BP, Butcher EA (2012) Investigation of period-doubling islands in milling with simultaneously engaged helical flutes. J Vib Acoust-Trans ASME 134(2):1–9. doi:10.1115/1.4 005022

Ding Y, Zhu LM, Zhang XJ, Ding H (2010) A full-discretization method for prediction of milling stability. Int J Mach Tools Manuf 50(5):502–509. doi:10.1016/j.ijmachtools.2010.01.003

Quo Q, Sun YW, Jiang Y (2012) On the accurate calculation of milling stability limits using third-order full-discretization method. Int J Mach Tools Manuf 62:61–66. doi:10.1016/j.ijmachtools.2012.05.001

Liu YL, Zhang DH, Wu BH (2012) An efficient full-discretization method for prediction of milling stability. Int J Mach Tools Manuf 63:44–48. doi:10.1016/j.ijmachtools.2012.07.008

Abellan-Nebot JV, Subirón FR (2010) A review of machining monitoring systems based on artificial intelligence process models. Int J Adv Manuf Technol 47(1–4):237–257. doi:10.1007/s00170-009-2191-8

Lamraoui M, Thomas M, El Badaoui M, Girardin F (2014a) Indicators for monitoring chatter in milling based on instantaneous angular speeds. Mech Syst Signal Proc 44(1–2):72–85. doi:10.1016/j.ymssp.2013.05.002

Lamraoui M, Thomas M, El Badaoui M (2014b) Cyclostationarity approach for monitoring chatter and tool wear in high speed milling. Mech Syst Signal Proc 44(1–2):177–198. doi:10.1016/j.ymssp.2013.05.001

Thaler T, Potočnik P, Bric I, Govekar E (2014) Chatter detection in band sawing based on discriminant analysis of sound features. Appl Acoust 77:114–121. doi:10.1016/j.apacoust.2012.12.004

Huang PL, Li JF, Sun J, Zhou J (2013) Vibration analysis in milling titanium alloy based on signal processing of cutting force. Int J Adv Manuf Technol 64(5–8):613–621. doi:10.1007/s00170-012-4039-x

Tangjitsitcharoen S, Pongsathornwiwat N (2013) Development of chatter detection in milling processes. Int J Adv Manuf Technol 65(5–8):919–927. doi:10.1007/s00170-012-4228-7

Tansel IN, Li M, Demetgul M, Bickraj K, Kaya B, Ozcelik B (2012) Detecting chatter and estimating wear from the torque of end milling signals by using Index Based Reasoner (IBR). Int J Adv Manuf Technol 58(1–4):109–118. doi:10.1007/s00170-010-2838-5

Liu Y, Wang XF, Lin J, Zhao W (2016) Early chatter detection in gear grinding process using servo feed motor current. Int J Adv Manuf Technol 83(9–12):1801–1810. doi:10.1007/s00170-015-7687-9

Weng JW, Zhong JG (2003) Application of Gabor transform to 3-D shape analysis. Acta Photonica Sinica 32(08):993–996

Postnikov EB, Lebedeva EA, Lavrova AI (2016) Computational implementation of the inverse continuous wavelet transform without a requirement of the admissibility condition. Appl Math Comput 282:128–136. doi:10.1016/j.amc.2016.02.013

Staszewski WJ, Worden K, Tomlinson GR (1997) Time-frequency analysis in gearbox fault detection using the Wigner-Ville distribution and pattern recognition. Mech Syst Signal Proc 11(5):673–692. doi:10.1006/mssp.1997.0102

Pachori RB, Nishad A (2016) Cross-terms reduction in the Wigner-Ville distribution using tunable-Q wavelet transform. Signal Process 120:288–304. doi:10.1016/j.sigpro.2015.07.026

Fu Y, Zhang Y, Zhou HM, Li DQ, Liu HQ, Qiao HY, Wang XQ (2016) Timely online chatter detection in end milling process. Mech Syst Signal Proc 75:668–688. doi:10.1016/j.ymssp.2016.01.003

Huang NE, Shen Z, Long SR, Wu MC, Shih HH, Zheng QA, Yen NC, Tung CC, Liu HH (1998) The empirical mode decomposition and the Hilbert spectrum for nonlinear non-stationary time series analysis. Proc R Soc Lond A 454:903–995

Huang NE, Wu ZH (2008) A review on Hilbert-Huang transform: method and its applications to geophysical studies. Rev Geophys 46(2):1–23. doi:10.1029/2007RG000228

Wu ZH, Huang NE (2009) Ensemble empirical mode decomposition: a noise assisted data analysis method. Adv Adapt Data Anal 1(1):1–41. doi:10.1142/S1793536909000047

Liu H, Tian HQ, Liang XF, Li YF (2015) New wind speed forecasting approaches using fast ensemble empirical model decomposition, genetic algorithm, mind evolutionary algorithm and artificial neural networks. Renew Energy 83:1066–1075. doi:10.1016/j.renene.2015.06.004

Wang SX, Zhang N, Wu L, Wang YM (2016) Wind speed forecasting based on the hybrid ensemble empirical mode decomposition and GA-BP neural network method. Renew Energy 94:629–636. doi:10.1016/j.renene.2016.03.103

Xian L, He KJ, Lai KK (2016) Gold price analysis based on ensemble empirical model decomposition and independent component analysis. Physica A 454:11–23. doi:10.1016/j.physa.2016.02.055

Yang CY, Wu TY (2015) Diagnostics of gear deterioration using EEMD approach and PCA process. Measurement 61:75–87. doi:10.1016/j.measurement.2014.10.026

Tabrizi A, Garibaldi L, Fasana A, Marchesiello S (2015) Early damage detection of roller bearings using wavelet packet decomposition, ensemble empirical mode decomposition and support vector machine. Meccanica 50(3):865–874. doi:10.1007/s11012-014-9968-z

Žvokelj M, Zupan S, Prebil I (2016) EEMD-based multiscale ICA method for slewing bearing fault detection and diagnosis. J Sound Vibr 370:394–423. doi:10.1016/j.jsv.2016.01.046

Xu J, Wang ZB, Tan C, Si L, Liu XH (2015) A cutting pattern recognition method for shearers based on improved ensemble empirical mode decomposition and a probabilistic neural network. Sensors 15(11):27721–27737. doi:10.3390/s151127721

Siddhpura M, Paurobally R (2012) A review of chatter vibration research in turning. Int J Mach Tools Manuf 61:27–47. doi:10.1016/j.ijmachtools.2012.05.007

Gray RM (2009) Entropy and information theory. Springer-Verlag, New York

Mandelbrot BB (1982) The fractal geometry of nature. Freeman, New York

Mandelbrot BB (2006) Fractal analysis and synthesis of fracture surface roughness and related forms of complexity and disorder. Int J Fract 138(1–4):13–17. doi:10.1007/s10704-006-0037-z

Bramowicz M, Braic L, Azem FA, Kulesza S, Birlik I (2016) Mechanical properties and fractal analysis of the surface texture of sputtered hydroxyapatite coatings. Appl Surf Sci 379:338–346. doi:10.1016/j.Apsusc.2016.04.077

Liu SC, Chang S (1997) Dimension estimation of discrete-time fractional Brownian motion with applications to image texture classification. IEEE Trans Image Process 6(8):1176–1184. doi:10.1109/83.605414

Neil G, Curtis KM (1997) Shape recognition using fractal geometry. Pattern Recogn 30(12):1957–1969. doi:10.1016/S0031-3203(96)00193-8

Lin KH, Lam KM, Siu WC (2001) Locating the eye in human face images using fractal dimensions. IEE Proc-Vis Image Signal Process 148(6):413–421. doi:10.1049/ip-vis:20010709

Sarker N, Chaudhuri BB (1994) An efficient differential box-counting approach to compute fractal dimension of image. IEEE Transactions on Systems, Man, and Cybernetics 24(1):115–120. doi:10.1109/21.259692

Maragos P, Sun FK (1993) Measuring the fractal dimension of signals: morphological covers and iterative optimization. IEEE Trans Signal Process 41(1):108–121. doi:10.1109/TSP.1993.193131

Cao HR, Zhou K, Ghen XF (2015) Chatter identification in end milling process based on EEMD and nonlinear dimensionless indicators. Int J Mach Tools Manuf 92:52–59. doi:10.1016/j.ijmachtools.2015.03.002

Shen JL, Hung JW, Lee LS (1998) Robust entropy-based end point detection for speech recognition in noisy environments. in: The International Conference on Spoken Language Processing, Incorporating the Australian International Speech Science and Technology Conference, Sydney Convention Centre, Sydney, Australia, November-December. DBLP 232–235

Insperger T, Stépán G (2004) Updated semi-discretization method for periodic delay- differential equations with discrete delay. Int J Numer Methods Eng 61(1):117–141. doi:10.1002/nme.1061

Xun J, Yan SZ (2008) A revised Hilbert-Huang transformation based on the neural networks and its application in vibration signal analysis of a deployable structure. Mech Syst Signal Proc 22(7):1705–1723. doi:10.1016/j.ymssp.2008.02.008

Insperger T, Stépán G, Bayly PV, Mann BP (2003) Multiple chatter frequencies in milling processes. J Sound Vib 262(2):333–345. doi:10.1016/S0022-460X(02)01131-8

Feng JL, Sun ZL, Jiang ZH, Yang L (2016) Identification of chatter in milling of Ti-6Al-4V titanium alloy thin-walled workpieces based on cutting force signals and surface topography. Int J Adv Manuf Technol 82(9–12):1909–1920. doi:10.1007/s00170-015-7509-0

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ji, Y., Wang, X., Liu, Z. et al. EEMD-based online milling chatter detection by fractal dimension and power spectral entropy. Int J Adv Manuf Technol 92, 1185–1200 (2017). https://doi.org/10.1007/s00170-017-0183-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0183-7