Abstract

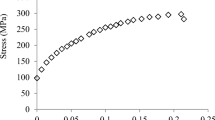

Formability of aluminum alloys at elevated temperatures are of vital importance to process design and numerical simulation of aluminum hot stamping. In this paper, the hot formability of AA7075 was investigated experimentally and numerically. Firstly, a series of hot uniaxial tensile tests were performed on a Gleeble 3500 thermomechanical simulator to determine constitutive relationships of AA7075 at different temperatures and strain rates. Based on these results, a uniaxial damage model was established, and further extended to a multi-axial continuum damage mechanics (CDM) based model with the consideration of stress state and strain path effects for hot stamping. Good agreement between model fitting and experimental results was achieved. Secondly, hot formability tests were conducted to investigate deformation characteristics at elevated temperatures. Finally, a finite element (FE) model using software ABAQUS with implemented the CDM model via subroutine was established and validated by corresponding experimentations. The developed FE model was utilized to investigate effects of process variables on material deformation and damage evolution in detail. It was found that formability can be improved with decreasing forming temperature and increasing forming speed. In addition, friction has a dominant effect on determining failure location.

Similar content being viewed by others

References

Liu YJ, Liu Y, Chen JN (2015) The impact of the Chinese automotive industry: scenarios based on the national environmental goals. J Clean Prod 96:102–109. doi:10.1016/j.jclepro.2014.05.015

Wang A, Zhong K, El Fakir O, Liu J, Sun C, Wang L, Lin J, Dean TA (2017) Springback analysis of AA5754 after hot stamping: experiments and FE modelling. Int J Adv Manuf Tech 89:1339–1352. doi:10.1007/s00170-016-9166-3

Fakir OE, Wang L, Balint D, Dear JP, Lin J, Dean TA (2014) Numerical study of the solution heat treatment, forming, and in-die quenching (HFQ) process on AA5754. Int J Mach Tool Manu 87:39–48. doi:10.1016/j.ijmachtools.2014.07.008

Mohamed MS, Foster AD, Lin J, Balint DS, Dean TA (2012) Investigation of deformation and failure features in hot stamping of AA6082: Experimentation and modelling. Int J Mach Tool Manu 53:27–38. doi:10.1016/j.ijmachtools.2011.07.005

Foster A, Dean TA, Lin J (2013) Process for forming aluminium alloy sheet components. European Patent, EP2324137

Wang L, Strangwood M, Balint D, Lin J, Dean TA (2011) Formability and failure mechanisms of AA2024 under hot forming conditions. Mat Sci Eng A 528:2648–2656. doi:10.1016/j.msea.2010.11.084

Zhou J, Wang B, Lin J, Fu L (2013) Optimization of an aluminum alloy anti-collision side beam hot stamping process using a multi-objective genetic algorithm. Arch Civ Mech Eng 13:401–411. doi:10.1016/j.acme.2013.01.008

Ablat MA, Qattawi A (2016) Numerical simulation of sheet metal forming: a review. Int J Adv Manuf Tech:1-16. doi:10.1007/s00170-016-9103-5

Zhang J, Deng Y, Zhang X (2013) Constitutive modeling for creep age forming of heat-treatable strengthening aluminum alloys containing plate or rod shaped precipitates. Mat Sci Eng A 563:8–15. doi:10.1016/j.msea.2012.10.055

Liu G, Zhang GJ, Ding XD, Sun J, Chen KH (2003) Modeling the strengthening response to aging process of heat-treatable aluminum alloys containing plate/disc- or rod/needle-shaped precipitates. Mat Sci Eng A 344:113–124. doi:10.1016/S0921-5093(02)00398-2

Worswick MJ, Chen ZT, Pilkey AK, Lloyd D, Court S (2001) Damage characterization and damage percolation modelling in aluminum alloy sheet. Acta Mater 49:2791–2803. doi:10.1016/S1359-6454(01)00163-X

Shi D, Hu P, Ying L (2016) Comparative study of ductile fracture prediction of 22MnB5 steel in hot stamping process. Int J Adv Manuf Tech 84:895–906. doi:10.1007/s00170-015-7754-2

Xu F, Lin J, Zhao S, Zhang H (2016) Research of the Gurson damage model of the different yield functions during the deep-drawing process. Int J Adv Manuf Tech:1-17. doi:10.1007/s00170-016-9873-9

Wu B, Li MQ, Ma DW (2012) The flow behavior and constitutive equations in isothermal compression of 7050 aluminum alloy. Mat Sci Eng A 542:79–87. doi:10.1016/j.msea.2012.02.035

Ma W, Wang B, Bian J, Tang X, Yang L, Huo Y (2015) A New Damage Constitutive Model for Thermal Deformation of AA6111 Sheet. Metall Mater Trans A 46:2748–2757. doi:10.1007/s11661-015-2823-6

Lin J, Dean TA (2005) Modelling of microstructure evolution in hot forming using unified constitutive equations. J Mater Process Tech 167:354–362. doi:10.1016/j.jmatprotec.2005.06.026

Lin J, Mohamed M, Balint D, Dean TA (2013) The development of continuum damage mechanics-based theories for predicting forming limit diagrams for hot stamping applications. Int J Damage Mech 23:684–701. doi:10.1177/1056789513507731

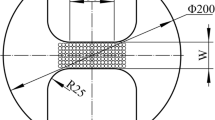

Shao Z, Li N, Lin J, Dean TA (2016) Development of a new biaxial testing system for generating forming limit diagrams for sheet metals under hot stamping conditions. Exp Mech 56:1489–1500. doi:10.1007/s11340-016-0183-9

Garrett RP, Lin J, Dean TA (2005) An investigation of the effects of solution heat treatment on mechanical properties for AA 6xxx alloys: experimentation and modelling. Int J Plasticity 21:1640–1657. doi:10.1016/j.ijplas.2004.11.002

Lin J, Liu Y, Farrugia D, Zhou M (2005) Development of dislocation-based unified material model for simulating microstructure evolution in multipass hot rolling. Philos Mag 85:1967–1987. doi:10.1080/14786430412331305285

Mohamed MS, Lin J, Wang L, Balint D (2013) Hybrid forming processes for production of lightweight high strength automotive panel parts. International Heat Treatment and Surface Engineering 4:160–165. doi:10.1179/174951410x12851626813014

Mohamed M, Shi ZS, Lin JG, Dean TA, Dear J (2015) Strain-based continuum damage mechanics model for predicting FLC of AA5754 under warm forming conditions. Applied Mechanics and Materials 784:460–467. doi:10.4028/www.scientific.net/AMM.784.460

Cao J, Lin J (2008) A study on formulation of objective functions for determining material models. Int J Mech Sci 50:193–204. doi:10.1016/j.ijmecsci.2007.07.003

Bieler TR, Eisenlohr P, Roters F, Kumar D, Mason DE, Crimp MA, Raabe D (2009) The role of heterogeneous deformation on damage nucleation at grain boundaries in single phase metals. Int J Plasticity 25:1655–1683. doi:10.1016/j.ijplas.2008.09.002

Mohamed M, Lin J, Foster A, Dean TA, Dear J (2014) A New Test Design for Assessing Formability of Materials in Hot Stamping. Procedia Engineering 81:1689–1694. doi:10.1016/j.proeng.2014.10.214

Yang XY, Lang LH, Liu KN, Cai GC, Guo C (2015) Prediction of forming limit diagram of AA7075-O aluminum alloy sheet based on modified M-K model. Journal of Beijing University of Aeronautics and Astronautics 41:675–679

Foster AD, Mohamed MS, Lin JG, Dean TA (2008) An investigation of lubrication and heat transfer for a sheet aluminium Heat, Form-Quench (HFQ) process. Steel Res Int 79:113–120

Bai Q, Mohamed M, Shi Z, Lin J, Dean TA (2016) Application of a continuum damage mechanics (CDM)-based model for predicting formability of warm formed aluminium alloy. Int J Adv Manuf Tech 88:3437–3446. doi:10.1007/s00170-016-8853-4

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, W., Wang, B. & Zheng, K. An experimental and numerical investigation on the formability of AA7075 sheet in hot stamping condition. Int J Adv Manuf Technol 92, 3299–3309 (2017). https://doi.org/10.1007/s00170-017-0419-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0419-6