Abstract

In this paper, parameter optimization of FSW of cryorolled AA2219 alloy was carried out to obtain defect free weld joint with maximum weld strength. To achieve this, artificial neural network (ANN) was used to model the relationship between the input parameters and the mechanical and corrosion properties (output) of the weld joints. The optimal FSW parameters were determined by genetic algorithm (GA). The feasible solution of the GA was tool rotational speed of 1005 rpm, tool travel speed of 20 mm/min and tool tilt angle of 3°. The feasible parameter was used to weld and check the ability of the parameter to produce better weld joint than the L9 orthogonal array parameters. The weld, subjected to the confirmation test, was investigated by means of metallurgical, mechanical, and corrosion testing. This process reduces the costs associated with trial runs to obtain optimal parameters and also the production cost of the cryorolled (CR) plate which is high.

Similar content being viewed by others

References

Bozkurt Y (2012) The optimization of friction stir welding process parameters to achieve maximum tensile strength in polyethylene sheets. Mater Des 35:440–445

Chien C-H, Lin W-B, Chen T (2011) Optimal FSW process parameters for aluminum alloys AA5083. J Chinese Inst Eng 34:99–105

Arora KS, Pandey S, Schaper M, Kumar R (2010) Microstructure evolution during friction stir welding of aluminum alloy AA2219. J Mater Sci Technol 26:747–753

Babu S, Elangovan K, Balasubramanian V, Balasubramanian M (2009) Optimizing friction stir welding parameters to maximize tensile strength of AA2219 aluminum alloy joints. Met Mater Int 15:321–330

Deepandurai K, Parameshwaran R (2015) Multi response optimization of FSW parameters for cast AA7075/SicP composite. Mater Manuf Process 31:1333–1341

Bozkurt Y, Bilici MK (2013) Application of Taguchi approach to optimize of FSSW parameters on joint properties of dissimilar AA2024-T3 and AA5754-H22 aluminum alloys. Mater Des 51:513–521

Shojaeefard MH, Khalkhali A, Akbari M, Tahani M (2013) Application of Taguchi optimization technique in determining aluminum to brass friction stir welding parameters. Mater Des 52:587–592

Koilraj M, Sundareswaran V, Vijayan S, Koteswara Rao SR (2012) Friction stir welding of dissimilar aluminum alloys AA2219 to AA5083—optimization of process parameters using Taguchi technique. Mater Des 42:1–7

Mohamed MA, Manurung YHP, Berhan MN (2015) Model development for mechanical properties and weld quality class of friction stir welding using multi-objective Taguchi method and response surface methodology. J Mech Sci Technol 29:2323–2331

Boulahem K, Salem SB, Bessrour J (2015) Surface roughness model and parametric welding optimization in friction stir welded AA2017 using Taguchi method and response surface methodology. Design and Modeling of Mechanical Systems - II. doi:10.1007/978-3-319-17527-0_9

Lakshminarayanan a K, Balasubramanian V (2008) Process parameters optimization for friction stir welding of RDE-40 aluminium alloy using Taguchi technique. Trans Nonferrous Met Soc China 18:548–554

Javadi Y, Sadeghi S, Najafabadi MA (2014) Taguchi optimization and ultrasonic measurement of residual stresses in the friction stir welding. Mater Des 55:27–34

Shojaeefard MH, Behnagh RA, Akbari M et al (2013) Modelling and pareto optimization of mechanical properties of friction stir welded AA7075/AA5083 butt joints using neural network and particle swarm algorithm. Mater Des 44:190–198

Gupta SK, Pandey K, Kumar R (2016) Multi-objective optimization of friction stir welding process parameters for joining of dissimilar AA5083/AA6063 aluminum alloys using hybrid approach. Proc Inst Mech Eng Part L J Mater Des Appl 0:1–11

Shojaeefard MH, Akbari M, Asadi P (2014) Multi objective optimization of friction stir welding parameters using FEM and neural network. Int J Precis Eng Manuf 15:2351–2356

Dewan MW, Huggett DJ, Warren Liao T et al (2016) Prediction of tensile strength of friction stir weld joints with adaptive neuro-fuzzy inference system (ANFIS) and neural network. Mater Des 92:288–299

Yaïci W, Entchev E (2016) Adaptive neuro-fuzzy inference system modelling for performance prediction of solar thermal energy system. Renew Energy 86:302–315

Babajanzade Roshan S, Behboodi Jooibari M, Teimouri R et al (2013) Optimization of friction stir welding process of AA7075 aluminum alloy to achieve desirable mechanical properties using ANFIS models and simulated annealing algorithm. Int J Adv Manuf Technol 69:1803–1818

Kannan TDB, Ramesh T, Sathiya P (2016) Application of artificial neural network modelling for optimization of Yb: YAG laser welding of Nitinol. Trans Indian Inst Metals. doi:10.1007/s12666-016-0973-x

Katherasan D, Jiju V. Elias, Sathiya P, Noorul Haq A (2014) Simulation and parameter optimization of flux cored arc welding using artificial neural network and particle swarm optimization algorithm. J Intell Manuf 25:67–76

Abbass MK, Hussein SK, Khudhair AA (2016) Optimization of mechanical properties of friction stir spot welded joints for dissimilar aluminum alloys (AA2024-T3 and AA 5754-H114). Arab J Sci Eng 41:4563–4572

Dehabadi VM, Ghorbanpour S, Azimi G (2016) Application of artificial neural network to predict Vickers microhardness of AA6061 friction stir welded sheets. J Cent South Univ 23:2146–2155

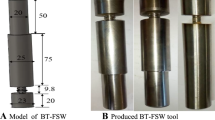

Babu KK, Panneerselvam K, Sathiya P et al (2016) Experimental investigation on friction stir welding of cryorolled Aa2219 aluminum alloy joints. Surf Rev Lett 24:1750001–1750017

Darzi Naghibi H, Shakeri M, Hosseinzadeh M (2016) Neural network and genetic algorithm based modeling and optimization of tensile properties in FSW of AA 5052 to AISI 304 dissimilar joints. Trans Indian Inst Metals 69:891–900

Panneerselvam K, Aravindan S, Noorul Haq A (2009) Hybrid of ANN with genetic algorithm for optimization of frictional vibration joining process of plastics. Int J Adv Manuf Technol 42:669–677

Tansel IN, Demetgul M, Okuyucu H, Yapici A (2010) Optimizations of friction stir welding of aluminum alloy by using genetically optimized neural network. Int J Adv Manuf Technol 48:95–101

Anand K, Barik BK, Tamilmannan K, Sathiya P (2015) Artificial neural network modeling studies to predict the friction welding process parameters of Incoloy 800H joints. Eng Sci Technol an Int J 18:394–407

Bilgin MB, Meran C, Canyurt OE (2015) Optimization of strength of friction stir welded joints for AISI 430 ferritic stainless steels by genetic algorithm. Int J Adv Manuf Technol 77:2221–2233

Kannan TDB, Kannan GR, Kumar BS, Baskar N (2014) Application of artificial neural network modeling for machining parameters optimization in drilling operation. Procedia Mater Sci 5:2242–2249

Zhao S, Bi Q, Wang Y, Shi J (2017) Empirical modeling for the effects of welding factors on tensile properties of bobbin tool friction stir-welded 2219-T87 aluminum alloy. Int J Adv Manuf Technol 90:1105–1118

Heidarzadeh A, Khodaverdizadeh H, Mahmoudi A, Nazari E (2012) Tensile behavior of friction stir welded AA 6061-T4 aluminum alloy joints. Mater Des 37:166–173

Li JQ, Liu HJ (2014) Optimization of welding parameters for the reverse dual-rotation friction stir welding of a high-strength aluminum alloy 2219-T6. Int J Adv Manuf Technol 76:1469–1478

Silva ACF, Braga DFO, de Figueiredo MAV, Moreira PMGP (2015) Ultimate tensile strength optimization of different FSW aluminium alloy joints. Int J Adv Manuf Technol 79:805–814

Nourani M, Milani AS, Yannacopoulos S (2015) On experimental optimization of friction stir welding of aluminum 6061: understanding processing-microstructure-property relations. Int J Adv Manuf Technol 79:1425–1441

Rahimzadeh Ilkhichi A, Soufi R, Hussain G et al (2014) Establishing mathematical models to predict grain size and hardness of the friction stir-welded AA 7020 aluminum alloy joints. Metall Mater Trans B Process Metall Mater Process Sci 46:357–365

Heidarzadeh A, Saeid T (2013) Prediction of mechanical properties in friction stir welds of pure copper. Mater Des 52:1077–1087

Azizi A, Barenji RV, Barenji AV, Hashemipour M (2016) Microstructure and mechanical properties of friction stir welded thick pure copper plates. Int J Adv Manuf Technol. doi:10.1007/s00170-015-8330-5

Karthikeyan R, Balasubramanian V (2010) Predictions of the optimized friction stir spot welding process parameters for joining AA2024 aluminum alloy using RSM. Int J Adv Manuf Technol 51:173–183

Heidarzadeh A, Saeid T, Khodaverdizadeh H et al (2013) Establishing a mathematical model to predict the tensile strength of friction stir welded pure copper joints. Metall Mater Trans B Process Metall Mater Process Sci 44:175–183

Effertz PS, Quintino L, Infante V (2017) The optimization of process parameters for friction spot welded 7050-T76 aluminium alloy using a Taguchi orthogonal array. Int J Adv Manuf Technol. doi:10.1007/s00170-017-0048-0

Heidarzadeh A, Mousavian RT, Khosroshahi RA et al (2017) Empirical model to predict mass gain of cobalt electroless deposition on ceramic particles using response surface methodology. Rare Metals 36:209–219

Salari E, Jahazi M, Khodabandeh A, Nanesa HG (2016) Friction stir lap welding of 5456 aluminum alloy with different sheet thickness: process optimization and microstructure evolution. Int J Adv Manuf Technol 82:39–48

Yuqing M, Liming K, Fencheng L et al (2017) Effect of tool pin-tip profiles on material flow and mechanical properties of friction stir welding thick AA7075-T6 alloy joints. Int J Adv Manuf Technol 88:949–960

Heidarzadeh A, Barenji RV, Esmaily M, Ilkhichi AR (2015) Tensile properties of friction stir welds of AA 7020 aluminum alloy. Trans Indian Inst Metals 68:757–767

Babajanzade Roshan S, Behboodi Jooibari M, Teimouri R et al (2013) Optimization of friction stir welding process of AA7075 aluminum alloy to achieve desirable mechanical properties using ANFIS models and simulated annealing algorithm. Int J Adv Manuf Technol 69:1803–1818

Heidarzadeh A, Saeid T (2016) Correlation between process parameters, grain size and hardness of friction-stir-welded Cu-Zn alloys. Rare Met 1–11. doi: 10.1007/s12598-016-0704-9

Yang T, Xiong J, Chen H (2016) Effect of process parameters on tensile strength in plasma-MIG hybrid welding for 2219 aluminum alloy. Int J Adv Manuf Technol 84:2413–2421

Farhanchi M, Neysari M, Vatankhah Barenji R et al (2015) Mechanical activation process for self-propagation high-temperature synthesis of ceramic-based composites: modeling and optimizing using response surface method. J Therm Anal Calorim 122:123–133

Li J, Tao F, Cheng Y, Zhao L (2015) Big data in product lifecycle management. Int J Adv Manuf Technol 81:667–684

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kamal Babu, K., Panneerselvam, K., Sathiya, P. et al. Parameter optimization of friction stir welding of cryorolled AA2219 alloy using artificial neural network modeling with genetic algorithm. Int J Adv Manuf Technol 94, 3117–3129 (2018). https://doi.org/10.1007/s00170-017-0897-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0897-6