Abstract

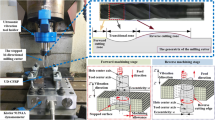

Carbon fiber reinforced plastic (CFRP) is used for various mechanical structures because of its superior mechanical and physical properties. Industrial applications of CFRP require high quality, efficiently drilled holes. However, it is difficult for conventional methods, such as drilling, helical milling, and so on to meet industry requirements. Therefore, this study proposed a novel method for drilling holes in CFRP products. This new method is performed by replacing the revolving motion of the tool in conventional helical milling (CHM) with conical pendulum motion, in which the tool axis is tilted toward the hole axis at a certain angle, consequently called tilted helical milling (THM). As a step toward the establishment of the new method, in this work, the hole formation process, the cross-sectional area of work materials removed per tool revolution, and the zero cutting speed point problem in THM were theoretically compared with those in CHM. Then, experiments were performed to confirm the theoretical analysis in terms of the variations in the cross section profile of the drilled hole, the drilling forces, the hole quality at entrance/exit, and the chip removal. The obtained results revealed that during hole drilling by THM, a circumferential V-groove exists between the end face of the tool and the bottom of the hole, whereas in CHM, this phenomenon does not occur. This fact is beneficial to timely chip removal, drilling force reduction, and zero cutting speed point problem avoidance. Subsequently, high quality holes can be successfully obtained with high efficiency by THM.

Similar content being viewed by others

References

Wang HJ, Sun J, Zhang DD, Guo K, Li JF (2016) The effect of cutting temperature in milling of carbon fiber reinforced polymer composites. Compos Part A Appl S 91:380–387

Cheng H, Zhang KF, Wang N, Luo B, Meng QX (2017) A novel six-state cutting force model for drilling-countersinking machining process of CFRP-Al stacks. Int J Adv Manuf Technol 89:2063–2076

Wei JC, Jiao GQ, Jia PR, Huang T (2013) The effect of interference fit size on the fatigue life of bolted joints in composite laminates. Compos Part B Eng 53:62–68

Alberdi A, Artaza T, Suarez A, Rivero A, Girot F (2016) An experimental study on abrasive waterjet cutting of CFRP/Ti6Al4V stacks for drilling operations. Int J Adv Manuf Technol 86:691–704

Thoppul SD, Finegan J, Gibson RF (2009) Mechanics of mechanically fastened joints in polymer–matrix composite structures—a review. Compos Sci Technol 69(3–4):301–329

Xu WX, Zhang LC (2016) Mechanics of fibre deformation and fracture in vibration-assisted cutting of unidirectional fibre-reinforced polymer composites. Int J Mach Tools Manuf 103:40–52

Abrao AM, Faria PE, Campos Rubio JC, Reis P, Davim JP (2007) Drilling of fiber reinforced plastics: a review. J Mater Process Technol 186(1–3):1–7

Zitoune R, Crouzeix L, Collombet F, Grunevald YH (2011) Behaviour of composite plates with drilled and moulded hole under tensile load. Compos Struct 93(9):2384–2391

Cong WL, Pei ZJ, Treadwell C (2014) Preliminary study on rotary ultrasonic machining of CFRP/Ti stacks. Ultrasonics 54(6):1594–1602

Liu J, Zhang DY, Qin LG, Yan LS (2012) Feasibility study of the rotary ultrasonic elliptical machining of carbon fiber reinforced plastics (CFRP). Int J Mach Tools Manuf 53(1):141–150

Liu JW, Baek DK, Ko TJ (2014) Chipping minimization in drilling ceramic materials with rotary ultrasonic machining. Int J Adv Manuf Technol 72:1527–1535

Pecat O, Rentsch R, Brinksmeier E (2012) Influence of milling process parameters on the surface integrity of CFRP. Procedia CIRP 1:466–470

Cadorin N, Zitoune R (2015) Wear signature on hole defects as a function of cutting tool material for drilling 3D interlock composite. Wear 332-333:742–751

Saoudi J, Zitoune R, Mezlini S, Gururaja S, Seitier P (2016) Critical thrust force predictions during drilling: analytical modeling and X-ray tomography quantification. Compos Struct 153(1):886–894

Soo SL, Shyha IS, Barnett T, Aspinwall DK, Sim WM (2012) Grinding performance and workpiece integrity when superabrasive edge routing carbon fibre reinforced plastic (CFRP) composites. CIRP Ann-Manuf Technol 61(1):295–298

Watanabe Y, Fujiwara M, Sato H, Takekoshi K, Tsuge H, Kaga T, Bando N, Yamagami S, Kurachi K, Yokoyama H (2011) Fabrication of functionally graded grinding wheel by a centrifugal mixed-powder method for CFRP-drilling applications. Int J Mater Prod Technol 42(1–2):29–45

Pereira RBD, Brandao LC, Paivab AP, Ferreira JR, Davim JP (2017) A review of helical milling process. Int J Mach Tools Manuf 120:27–48

Wang HY, Qin XD, Li H, Tan YQ (2016) A comparative study on helical milling of CFRP/Ti stacks and its individual layers. Int J Adv Manuf Technol 86(5):1973–1983

Li ZQ, Liu Q, Ming XZ, Wang X, Dong YF (2014) Cutting force prediction and analytical solution of regenerative chatter stability for helical milling operation. Int J Adv Manuf Technol 73(1):433–442

Wang HY, Qin XD (2016) A mechanistic model for cutting force in helical milling of carbon fiber-reinforced polymers. Int J Adv Manuf Technol 82(9):1485–1494

Li ZL, Ding Y, Zhu LM (2017) Accurate cutting force prediction of helical milling operations considering the cutter runout effect. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-017-0464-1

Deitert L Orbital drilling. Sae Tech Pap. https://doi.org/10.4271/2011-01-2533

Denkena B, Boehnke D, Dege JH (2008) Helical milling of CFRP-titanium layer compounds. CIRP J Manuf Sci Technol 1(2):64–69

Liu J, Chen G, Ji CH (2014) An investigation of workpiece temperature variation of helical milling for carbon fiber reinforced plastics (CFRP). Int J Mach Tools Manuf 86:89–103

Lindqvist R, Eriksson I, Wolf M (2011) Orbital drilling of sandwich constructions for space applications. Sae Technical Papers. https://doi.org/10.4271/2001-01-2571

Wu YB, Wang Q, Nomura M (2016) Proposal of tilt helical milling method for hole creation of carbon fiber reinforced plastic (CFRP). Adv Mater Res 1136:190–195

Wang Q, Wu YB, Nomura M (2015) Influence of tool eccentricity in hole creation of CFRP by tilt helical milling. JSPE. 10.11522/pscjspe.2015A.0_173

Wang Q, Wu YB, Nomura M, Gu J (2016) On the hole formation in the hole creation of CFRP by tilt helical milling. JSPE. 10.11522/pscjspe.2016S.0_671

Tanaka H, Ohta K, Takizawa R, Yanagi K (2012) Experimental study on tilted planetary motion drilling for CFRP. Procedia CIRP 1:443–448

Ohta K, Tanaka H, Takizawa R (2012) Development of tilted planetary drilling system. Procedia CIRP 1:681–682

Wang HY, Qin XD, Li H, Ren CZ (2012) Analysis of cutting forces in helical milling of carbon fiber–reinforced plastics. P I Mech Eng B-J Eng 227(1):62–74

Funding

A portion of this work was conducted under the financial supports of the Mikiya Science and Technology Promotion Foundation and the Mazak Foundation. This research is supported by the National Natural Science Foundation of China (Grant No. 51405218).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Q., Wu, Y., Bitou, T. et al. Proposal of a tilted helical milling technique for high quality hole drilling of CFRP: kinetic analysis of hole formation and material removal. Int J Adv Manuf Technol 94, 4221–4235 (2018). https://doi.org/10.1007/s00170-017-1106-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1106-3