Abstract

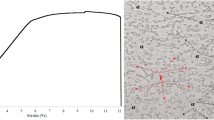

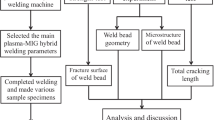

Plasma-MIG (metal inert-gas) hybrid welding is an advanced welding technology of aluminum alloys, which integrates the advantages of deep penetration in plasma arc welding and excellent filling ability in MIG welding. In this paper, the 5083 aluminum alloy plates with 6-mm thickness were welded using paraxial plasma-MIG hybrid welding. The influence of processing parameters such as the welding speed, plasma current, MIG current, and plasma gas flow rate on the weld forming was investigated, and the microstructure and mechanical behavior of welded joint under the typical parameters were studied. Both the penetration depth and weld width decreased with the increase of welding speed, increased with the increase of MIG current. While plasma arc current and plasma gas flow rate mainly affected penetration depth. The welding joint underwent the different thermal cycles in the different regions, which resulted in the different microstructure. Compared with the lower part of welding joint, the secondary phases in the upper part were bulkier and the dendrite arm spacing was wider, and the width in the partially melted zone (PMZ) was smaller. The tensile strength and the elongation of the welding joint were 274 MPa and 12.42%, which is approximately 85.63 and 95% of that of base metal, respectively.

Similar content being viewed by others

References

Golumbfskie W, Tran KN, Noland J, Park R, Stiles D, Grogan G, Wong C (2015) Survey of detection, mitigation, and repair technologies to address problems caused by sensitization of Al-Mg allows on navy ships. Corrosion 72:314–328

Zhu CX, Tang XH, He Y, Lu FG, Cui HC (2016) Study on arc characteristics and their influences on weld bead geometry in narrow gap GMAW of 5083 Al-alloy. Int J Adv Manuf Technol 90(9–12):2513–2525

Sevim I, Hayat F, Kaya Y, Kahraman N, Şahin S (2013) The study of MIG weldability of heat-treated aluminum alloys. Int J Adv Manuf Technol 66(9–12):1825–1834

Bunaziv I, Akselsen OM, Salminen A, Unt A (2016) Fiber laser-MIG hybrid welding of 5 mm 5083 aluminum alloy. J Mater Process Technol 233:107–114

Tasak E, Jastrzębski A (2012) The influence of pulsation of the MIG arc on the structure of aluminium alloy welds. Weld Int 26(12):944–948

Tashiro S, Sawato H, Tanaka M (2011) Experimental observation of cleaning action of cathode spots in AC TIG welding of aluminum plates. Q J Jpn Weld Soc 29(3):5–8

Yang T, Xiong J, Chen H (2016) Effect of process parameters on tensile strength in plasma-MIG hybrid welding for 2219 aluminum alloy. Int J Adv Manuf Technol 84(9–12):2413–2421

Yan S, Chen H, Zhu Z, Gou G (2014) Hybrid laser-metal inert gas welding of Al–Mg–Si alloy joints: microstructure and mechanical properties. Mater Des 61(9):160–167

Faraji AH, Goodarzi M, Seyedein SH, Barbieri G, Maletta C (2015) Numerical modeling of heat transfer and fluid flow in hybrid laser–TIG welding of aluminum alloy AA 6082. Int J Adv Manuf Technol 77(9–12):2067–2082

Atabaki MM, Ma J, Liu W, Kovacevic R (2015) Hybrid laser/arc welding of advanced high strength steel to aluminum alloy by using structural transition insert. Mater Des 75:120–135

D’Urso G, Giardini C, Lorenzi S, Pastore T (2014) Fatigue crack growth in the welding nugget of FSW joints of a 6060 aluminum alloy. J Mater Process Technol 214(10):2075–2084

Aval HJ, Serajzadeh S, Kokabi AH (2011) Evolution of microstructures and mechanical properties in similar and dissimilar friction stir welding of AA5086 and AA6061. Mater Sci Eng A 528:8071–8083

Birol Y, Kasman S (2013) Effect of welding parameters on microstructure and mechanical properties of friction stir welded EN AW 5083 H111 plates. Mater Sci Technol 29(11):1354–1362

Hertel M, Füssel U, Schnick M (2014) Numerical simulation of the plasma–MIG process—interactions of the arcs, droplet detachment and weld pool formation. Weld World 58(1):85–92

Resende AAD, Ferraresi VA, Scotti A, Dutra JC (2011) Influence of welding current in plasma–MIG weld process on the bead weld geometry and wire fusion rate. Weld Int 25(12):910–916

Essers WG, Liefkens AC (1972) Plasma-MIG welding developed by Philips. Mach Prod Eng 1(11):632–633

Bai Y, Gao HM, Wu L, Ma ZH, Cao N (2010) Influence of plasma-MIG welding parameters on aluminum weld porosity by orthogonal test. Trans Nonferrous Metals Soc China 20(8):1392–1396

Bai Y, Gao HM, Qiu L (2010) Droplet transition for plasma-MIG welding on aluminium alloys. Trans Nonferrous Metals Soc China 20(12):2234–2239

Ono K, Liu ZJ, Era T, Uezono T, Ueyama T, Tanaka M, Nakata K (2003) Development of a plasma MIG welding system for aluminum. Weld Int 23(11):805–809

Hong HT, Han YQ, Du MH, Tong JH (2016) Investigation on droplet momentum in VPPA-GMAW hybrid welding of aluminum alloys. Int J Adv Manuf Technol 86(5–8):2301–2308

Wang CH, Du B (2009) Investigation and application of plasma-MIG/MAG hybird welding technology. Weld Join 12:62–64

Chen SJ, Fan J, Zhang JL, Huang N, Zhang YM (2013) Principle of weld formation in variable polarity keyhole plasma arc transverse welding of aluminum alloy. Trans China Weld Inst 34(4):1–6

Cao Y, Li HY, Liang ZM, Wang DL (2017) Effect of water cooling on the microstructure and mechanical properties of 6N01 aluminum alloy P-MIG-welded joints. J Mater Eng Perform 26(8):3929–3938

Cai DT, Han SG, Zheng SD, Yan DJ, Luo JQ, Liu XL, Luo ZY (2016) Plasma-MIG hybrid welding process of 5083 marine aluminum alloy. Mater Sci Forum 850:519–525

Funding

This study was funded by the Foundation of Key Laboratory of Advanced Welding Technology of Jiangsu Province and Jiangsu University of Science and Technology (JSAWT-11-02).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, Y., Pan, H., Ren, L. et al. An investigation on plasma-MIG hybrid welding of 5083 aluminum alloy. Int J Adv Manuf Technol 98, 1433–1440 (2018). https://doi.org/10.1007/s00170-018-2206-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2206-4