Abstract

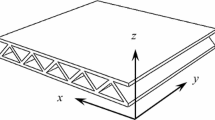

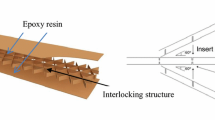

Bend-forming is an efficient and economical method to manufacture curved sandwich panels, and the major concerns for fabricating precise products are forming characteristics and springback prediction. In this paper, numerical simulation, analytical approach, and forming experiments were conducted to assess the multi-point cylindrical bend-forming process of bi-directional trapezoidal sandwich panel. Analysis was performed on the deformation characteristics, regularity, and forming defects of sandwich panel in the early stage. And afterwards, equivalent elastic constants of the core layer were deduced by the semi-analytic approach combined with finite element method (FEM). On this basis, a theoretical model was established to calculate bending moments and predict springback within formable range. The results indicate that the stress of face sheet in the welded area was obviously lower than that in the suspended area. The core cell was primarily deformed by changing the angle between the inclined plane and the platform, and the deformation of the cell layer mainly occurred in the transition surface area. The dimple and straight plane effect are the most common forming defects during the bending process. The main factors that affect the forming defects are face sheet thickness and bending radius. The springback amount of the sandwich panel approximates the equivalent thickness plate. Thus, it is easy to control the forming precision for small springback, and the springback ratio increases with the increase of bending curvature radius. The springback in theoretical model and experiment has an error of less than 1.0 mm, verifying the accuracy of the theoretical prediction model.

Similar content being viewed by others

References

Noor AK, Burton WS, Bert CW (1996) Computational models for sandwich panels and shells. Appl Mech Rev 49(3):155–199

Gibson LJAA, Ashby MF (2014) Cellular solids: structure and properties, vol 33. Cambridge University Press, Cambridge, pp 487–488

Evans AG, Hutchinson JW, Ashby MF (1988) Multifunctionality of cellular metal systems. Prog Mater Sci 43(3):171–221

Librescu L, Hause T (2000) Recent developments in the modeling and behavior of advanced sandwich constructions: a survey. Compos Struct 48(1–3):1–17

Gibson LJ (2000) Mechanical behavior of metallic foams. Annu Rev Mater Sci 30(30):191–227

Jarghohe L (2004) Advances in the structural modeling of elastic sandwich panels. Mech Compos Mater Struct 11(4–5):395–424

Wadley HNG, Fleck NA, Evans AG (2003) Fabrication and structural performance of periodic cellular metal sandwich structures. Compos Sci Technol 63(16):2331–2343

Allen HG, Neal BG (1969) Analysis and design of structural sandwich panels. Pergamon, New York

Carlsson LA, Nordstrand T, Westerlind BO (2001) On the elastic stiffnesses of corrugated core sandwich. J Sandw Struct Mater 3(4):253–267

Frostig Y, Baruch M, Vilnay O, Sheinman I (1992) High-order theory for sandwich-beam behavior with transversely flexible core. J Eng Mech 118(5):1026–1043

Kheirikhah MM, Khalili SMR, Fard KM (2012) Biaxial buckling analysis of soft-core composite sandwich plates using improved high-order theory. Eur J Mech A Solids 31(1):54–66

Daniel IM, Gdoutos EE (2008) Failure modes of composite sandwich beams. J Theor App Mech-Pol 35(1–3):105–118

Zhu S, Chai GB (2013) Damage and failure mode maps of composite sandwich panel subjected to quasi-static indentation and low velocity impact. Compos Struct 101(15):204–214

Jin F, Chen H, Zhao L et al (2013) Failure mechanisms of sandwich composites with orthotropic integrated woven corrugated cores: Experiments. Compos Struct 98(3):53–58

Liu J, Xue W (2016) Unconstrained bending and springback behaviors of aluminum-polymer sandwich sheets. Int J Adv Manuf Technol 2016:1–13

Parsa MH, Mohammadi SV, Aghchai AJ (2014) Al3105/polypropylene/Al3105 laminates springback in V-die bending. Int J Adv Manuf Technol 75(5–8):849–860

Mohammadi SV, Parsa MH, Aghchai AJ (2014) Simplified springback prediction in Al/PP/Al sandwich air bending. J Sandw Struct Mater 17(3):217–237

Bart-Smith H, Hutchinson JW, Evans AG (2001) Measurement and analysis of the structural performance of cellular metal sandwich construction. Int J Mech Sci 43(8):1945–1963

Mccormack TM, Miller R, Kesler O, Gibson LJ (1999) Failure of sandwich beams with metallic foam cores. Int J Solids Struct 38(28):4901–4920

Bart-Smith H, Hutchinson JW, Fleck NA, Evans AG (2002) Influence of imperfections on the performance of metal foam core sandwich panels. Int J Solids Struct 39(19):4999–5012

Mohan K, Hon YT, Idapalapati S, Hong PS (2005) Failure of sandwich beams consisting of alumina face sheet and aluminum foam core in bending. Mater Sci Eng A 409(1–2):292–301

Mohr D (2005) On the role of shear strength in sandwich sheet forming. Int J Solids Struct 42(5):1491–1512

Li MZ, Cai ZY, Sui Z, Yan QG (2002) Multi-point forming technology for sheet metal. J Mater Process Technol 129:333–338

Cai ZY, Wang SH, Xu XD, Li MZ (2009) Numerical simulation for the multi-point stretch forming process of sheet metal. J Mater Process Technol 209:396–407

Cai ZY, Wang SH, Li MZ (2008) Numerical investigation of multi-point forming process for sheet metal: wrinkling, dimpling and springback. Int J Adv Manuf Technol 37:927–936

Liu CG, Li MZ, Fu WZ (2008) Principles and apparatus of multi-point forming for sheet metal. Int J Adv Manuf Technol 35(11–12):1227–1233

Wang SH, Cai ZY, Li MZ, Lan YW (2012) Numerical simulation on the local stress and local deformation in multi-point stretch forming process. Int J Adv Manuf Technol 60:901–911

Vinson JR, Sierakowski RL, Bert CW (2008) The behavior of structures composed of composite materials. Springer, Netherlands

Libove C and Batdorf SB (1948) A general small-deflection theory for flat sandwich plates. In NACA TN 1526 Washington, DC also NACA Rept. 899

Funding

This study received financial support from the National Science Foundation of China (Grant No. 51575231).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liang, XB., Cai, ZY. & Zhang, X. Forming characteristics analysis and springback prediction of bi-directional trapezoidal sandwich panels in the multi-point bend-forming. Int J Adv Manuf Technol 98, 1709–1720 (2018). https://doi.org/10.1007/s00170-018-2316-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2316-z