Abstract

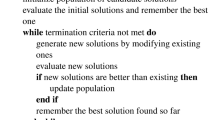

In the field of metal rolling, the quality of steel roller’s surface is significant for the final rolling products, e.g., metal sheets or foils. The surface roughness of steel rollers must fall into a stringent range to guarantee the proper rolling force between the sheet and the roller. To achieve the surface roughness requirement, multiple grinding passes have to be implemented. The current process parameter design for multi-pass roller grinding mainly relies on the knowledge of the experienced engineers. This always requires time tedious “trial and error” and is insufficient to work out cases: (1) multi-pass with complex interaction for one pass with its neighboring passes; (2) large number of process parameters setup; (3) multiple process objectives and constrains. In this paper, a process planning method for multi-objective optimization is proposed with a hybrid particle swarm optimization while incorporating the response surface model of the surface roughness evolution. The hybrid particle swarm optimization regards the entire grinding process parameters (from rough grinding, semi-finish grinding, finish grinding to spark-out grinding) as a whole, and realizes the parameter optimization by considering multiple objectives and constrains. The establishment of the response surface model of surface roughness evolution is capable to incorporate the inter-correlation of neighboring passes into the multi-pass parameter optimization. Finally, the experimental verification was implemented to verify the effectiveness of the proposed method. The error between predicted roughness and experimental roughness is less than 16.53%, and the grinding efficiency is improved by 17.00% compared with the empirical optimal process parameters.

Similar content being viewed by others

References

Weiss M, Abeyrathna B, Rolfe B, Abee A, Wolfkamp H (2017) Effect of coil set on shape defects in roll forming steel strip. J Manuf Process 25:8–15

Tu N, Luo X, Chai T (2011) Two-stage method for solving large-scale hot rolling planning problem in steel production. In: 18th international federation of automatic control world congress, Milano, pp 12120-12125

Palit Sagar S, Murthy GVS, Das TK, Prakash A, Goel US, Venugopalan T (2013) Surface wave based ultrasonic technique for finding the optimal grinding condition of high speed steel (HSS) work rolls. Steel Research International 84(2):163–168

Li C, Chen X, Tang Y, Li L (2017) Selection of optimum parameters in multi-pass face milling for maximum energy efficiency and minimum production cost. J Clean Prod 140:1805–1818

Wang G, Ma Z (2017) Hybrid particle swarm optimization for first-order reliability method. Comput Geotech 81:49–58

Liu YM, Niu B (2013) Theory and practice of new particle swarm optimization. China Science Publishing & Media Ltd, Beijing

Yusup N, Zain AM, Hashim SZM (2012) Evolutionary techniques in optimizing machining parameters: review and recent applications (2007–2011). Expert Syst Appl 39(10):9909–9927

Neseli S, Asilturk I, Celik L (2012) Determining the optimum process parameter for grinding operations using robust process. J Mech Sci Technol 26(11):3587–3595

Kwak JS, Sim SB, Jeong YD (2006) An analysis of grinding power and surface roughness in external cylindrical grinding of hardened SCM440 steel using the response surface method. Int J Mach Tool Manu 46(3–4):304–312

Janardhan M, Krishna D (2011) Determination and optimization of cylindrical grinding process parameters using Taguchi method and regression analysis. Int J Eng Sci Technol 3(7):5659–5665

Thiagarajan C, Sivaramakrishnan R, Somasundaram S (2012) Modeling and optimization of cylindrical grinding of Al/SiC composites using genetic algorithms. J Braz Soc Mech Sci Eng 34(1):32–40

Rudrapati R, Pal PK, Bandyopadhyay A (2016) Modeling and optimization of machining parameters in cylindrical grinding process. Int J Adv Manuf Technol 82(9–12):2167–2182

Zhang Y, Li B, Yang J, Liang S (2018) Modeling and optimization of alloy steel 20CrMnTi grinding process parameters based on experiment investigation. Int J Adv Manuf Technol 95(5–8):1859–1873

Zhang H, Deng Z, Fu Y, Lv L, Yan C (2017) A process parameters optimization method of multi-pass dry milling for high efficiency, low energy and low carbon emissions. J Clean Prod 148:174–184

Li Y, Liu Q (2015) Service-oriented research on multi-pass milling parameters optimization for green and high efficiency. J Mech Eng 51(11):89–98

Mellal MA, Williams EJ (2015) Cuckoo optimization algorithm for unit production cost in multi-pass turning operations. Int J Adv Manuf Technol 76(1–4):647–656

Lu C, Gao L, Li X, Chen P (2016) Energy-efficient multi-pass turning operation using multi-objective backtracking search algorithm. J Clean Prod 137:1516–1531

Chauhan P, Pant M, Deep K (2015) Parameter optimization of multi-pass turning using chaotic PSO. Int J Mach Learn Cybern 6(2):319–337

Xu S, Wang Y, Huang F (2017) Optimization of multi-pass turning parameters through an improved flower pollination algorithm. Int J Adv Manuf Technol 89(1–4):503–514

Thepsonthi T, Özel T (2012) Multi-objective process optimization for micro-end milling of Ti-6Al-4V titanium alloy. Int J Adv Manuf Technol 63(9–12):903–914

Yang W, Guo Y, Liao W (2011) Multi-objective optimization of multi-pass face milling using particle swarm intelligence. Int J Adv Manuf Technol 56(5–8):429–443

Kennedy J, Eberhart R (1995) Particle swarm optimization. In: Proceeding of the IEEE international conference on neural networks (ICNN 1995), Perth, vol 4, pp 1942-1948

Eberhart RC, Shi Y (2001) Particle swarm optimization: developments, applications and resources. In: Congress on evolutionary computation (CEC 2001), Seoul, pp 81-86

Shi Y, Eberhart RC (1998) Parameter selection in particle swarm optimization. In: Proceedings of the Seventh Annual Conference on Evolutionary Programming, San Diego, pp 591–600

Eberhart RC, Shi Y (2001) Tracking and optimizing dynamic systems with particle swarms. In: Congress on evolutionary computation (CEC 2001), Seoul, pp 94-100

Lu H, Yen GG (2003) Rank-density-based multiobjective genetic algorithm and benchmark test function study. IEEE Trans Evol Comput 7(4):325–343

Yang W, Guo Y, Liao W (2011) Optimization of multi-pass face milling using a fuzzy particle swarm optimization algorithm. Int J Adv Manuf Technol 54(1–4):45–57

Box G, Draper N (1987) Empirical model-building and response surfaces. Wiley, Hoboken

Campatelli G, Lorenzini L, Scippa A (2014) Optimization of process parameters using a response surface method for minimizing power consumption in the milling of carbon steel. J Clean Prod 66:309–316

Acknowledgements

The authors would also like to thank the support from Tsinghua University Initiative Scientific Research Program and Tsinghua-RWTH Aachen Collaborative Innovation Funding.

Funding

This research is supported by Project 2017ZX04007001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Z., Li, X., Wang, L. et al. Development of a hybrid particle swarm optimization algorithm for multi-pass roller grinding process optimization. Int J Adv Manuf Technol 99, 97–112 (2018). https://doi.org/10.1007/s00170-018-2458-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2458-z