Abstract

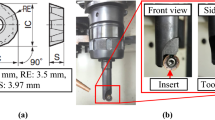

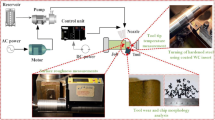

In machining of soft alloys, the sticky nature of localized material instigated by tool-work interaction exacerbates the tribological attitude and ultimately demeans it machinability. Moreover, the endured severe plastic deformation and originated thermal state alter the metallurgical structure of machined surface and chips. Also, the used tool edges are worn/damaged. Implementation of cooling-lubrication (C/L) agents to reduce friction at faying surfaces can ameliorate overall machinability. That is why, this paper deliberately discussed the influence of pure C/L methods, i.e., such as dry cutting (DC) and nitrogen cooling (N2), as well as hybrid C/L strategies, i.e., nitrogen minimum quantity lubrication (N2MQL) and Ranque–Hilsch vortex tube (RHVT) N2MQL conditions in turning of Al 7075-T6 alloy, respectively. With respect to the variation of cutting speed and feed rate, at different C/Ls, the surface roughness, tool wear, and chips are studied by using SEM and 3D topographic analysis. The mechanism of heat transfer by the cooling methods has been discussed too. Furthermore, the new chip management model (CMM) was developed under all C/L conditions by considering the waste management aspects. It was found that the R-N2MQL has the potential to reduce the surface roughness up to 77% and the tool wear up to 118%. This significant improvement promotes sustainability in machining industry by saving resources. Moreover, the CMM showed that R-N2MQL is more attractive for cleaner manufacturing system due to a higher recyclability, remanufacturing, and lower disposal of chips.

Similar content being viewed by others

References

Mia M, Singh G, Gupta MK, Sharma VS (2018) Influence of Ranque-Hilsch vortex tube and nitrogen gas assisted MQL in precision turning of Al 6061-T6. Precis Eng 53:289–299. https://doi.org/10.1016/j.precisioneng.2018.04.011

Camposeco-Negrete C (2015) Optimization of cutting parameters using response surface method for minimizing energy consumption and maximizing cutting quality in turning of AISI 6061 T6 aluminum. J Clean Prod 91:109–117

Sartori S, Ghiotti A, Bruschi S (2017) Temperature effects on the Ti6Al4V machinability using cooled gaseous nitrogen in semi-finishing turning. J Manuf Process 30:187–194. https://doi.org/10.1016/j.jmapro.2017.09.025

Gupta MK, Sood P, Sharma VS (2016) Optimization of machining parameters and cutting fluids during nano-fluid based minimum quantity lubrication turning of titanium alloy by using evolutionary techniques. J Clean Prod 135:1276–1288

Gupta MK, Sood PK, Singh G, Sharma VS (2017) Sustainable machining of aerospace material–Ti (grade-2) alloy: modeling and optimization. J Clean Prod 147:614–627

Singh S, Ramakrishna S, Gupta MK (2017) Towards zero waste manufacturing: a multidisciplinary review. J Clean Prod 168:1230–1243. https://doi.org/10.1016/j.jclepro.2017.09.108

Hegab HA, Darras B, Kishawy HA (2018) Towards sustainability assessment of machining processes. J Clean Prod 170:694–703. https://doi.org/10.1016/j.jclepro.2017.09.197

Gupta MK, Sood P (2017) Machining comparison of aerospace materials considering minimum quantity cutting fluid: a clean and green approach. Proc Inst Mech Eng C J Mech Eng Sci 231(8):1445–1464

Singh G, Sharma VS (2017) Analyzing machining parameters for commercially puretitanium (grade 2), cooled using minimum quantity lubrication assisted by a Ranque-Hilsch vortex tube. Int J Adv Manuf Technol 88(9–12):2921–2928

Mulyana T, Rahim EA, Md Yahaya SN (2017) The influence of cryogenic supercritical carbon dioxide cooling on tool wear during machining high thermal conductivity steel. J Clean Prod 164:950–962. https://doi.org/10.1016/j.jclepro.2017.07.019

Mia M, Morshed MS, Kharshiduzzaman M, Razi MH, Mostafa MR, Rahman SMS, Ahmad I, Hafiz MT, Kamal AM (2018) Prediction and optimization of surface roughness in minimum quantity coolant lubrication applied turning of high hardness steel. Measurement 118:43–51. https://doi.org/10.1016/j.measurement.2018.01.012

Boswell B, Islam MN, Davies IJ, Ginting YR, Ong AK (2017) A review identifying the effectiveness of minimum quantity lubrication (MQL) during conventional machining. Int J Adv Manuf Technol 92(1):321–340. https://doi.org/10.1007/s00170-017-0142-3

Elmunafi MHS, Mohd Yusof N, Kurniawan D (2015) Effect of cutting speed and feed in turning hardened stainless steel using coated carbide cutting tool under minimum quantity lubrication using castor oil. Adv Mech Eng 7(8):1687814015600666

Khan A, Maity K (2018) Influence of cutting speed and cooling method on the machinability of commercially pure titanium (CP-Ti) grade II. J Manuf Process 31:650–661. https://doi.org/10.1016/j.jmapro.2017.12.021

Dureja J, Singh R, Singh T, Singh P, Dogra M, Bhatti MS (2015) Performance evaluation of coated carbide tool in machining of stainless steel (AISI 202) under minimum quantity lubrication (MQL). International Journal of Precision Engineering and Manufacturing-Green Technology 2(2):123–129

Kouam J, Songmene V, Balazinski M, Hendrick P (2015) Effects of minimum quantity lubricating (MQL) conditions on machining of 7075-T6 aluminum alloy. Int J Adv Manuf Technol 79(5):1325–1334. https://doi.org/10.1007/s00170-015-6940-6

Giasin K, Ayvar-Soberanis S, Hodzic A (2016) Evaluation of cryogenic cooling and minimum quantity lubrication effects on machining GLARE laminates using design of experiments. J Clean Prod 135:533–548. https://doi.org/10.1016/j.jclepro.2016.06.098

Elshwain AEI, Redzuan N, Noordin MY (2014) Effect of nitrogen gas and nitrogen-oil-mist conditions when turning of STAVAX ESR steel. In: Applied Mechanics and Materials, vol 660. Trans Tech Publ, pp 13–17

Rubio E, Agustina B, Marín M, Bericua A (2015) Cooling systems based on cold compressed air: a review of the applications in machining processes. Procedia Engineering 132:413–418

Ginting YR, Boswell B, Biswas WK, Islam MN (2016) Environmental generation of cold air for machining. Procedia CIRP 40:648–652

Mia M (2017) Multi-response optimization of end milling parameters under through-tool cryogenic cooling condition. Measurement 111(Supplement C):134–145. https://doi.org/10.1016/j.measurement.2017.07.033

Mia M, Al Bashir M, Dhar NR (2016) Modeling of principal flank wear: an empirical approach combining the effect of tool, environment and workpiece hardness. Journal of the Institution of Engineers (India): Series C 97(4):517–526

Bergman TL, Incropera FP (2011) Introduction to heat transfer. John Wiley & Sons, Hoboken

Duchosal A, Serra R, Leroy R, Hamdi H (2015) Numerical optimization of the minimum quantity lubrication parameters by inner canalizations and cutting conditions for milling finishing process with Taguchi method. J Clean Prod 108:65–71

Krolczyk GM, Nieslony P, Maruda RW, Wojciechowski S (2017) Dry cutting effect in turning of a duplex stainless steel as a key factor in clean production. J Clean Prod 142:3343–3354. https://doi.org/10.1016/j.jclepro.2016.10.136

Pu Z, Outeiro J, Batista A, Dillon O, Puleo D, Jawahir I (2012) Enhanced surface integrity of AZ31B Mg alloy by cryogenic machining towards improved functional performance of machined components. Int J Mach Tools Manuf 56:17–27

Mark Benjamin D, Sabarish VN, Hariharan MV, Samuel Raj D (2018) On the benefits of sub-zero air supplemented minimum quantity lubrication systems: an experimental and mechanistic investigation on end milling of Ti-6-Al-4-V alloy. Tribol Int 119:464–473. https://doi.org/10.1016/j.triboint.2017.11.021

Debnath S, Reddy MM, Yi QS (2014) Environmental friendly cutting fluids and cooling techniques in machining: a review. J Clean Prod 83:33–47

Mia M, Dhar NR (2016) Response surface and neural network based predictive models of cutting temperature in hard turning. J Adv Res 7(6):1035–1044

Bagherzadeh A, Budak E (2018) Investigation of machinability in turning of difficult-to-cut materials using a new cryogenic cooling approach. Tribol Int 119:510–520. https://doi.org/10.1016/j.triboint.2017.11.033

Pervaiz S, Rashid A, Deiab I, Nicolescu CM (2016) An experimental investigation on effect of minimum quantity cooling lubrication (MQCL) in machining titanium alloy (Ti6Al4V). Int J Adv Manuf Technol 87(5–8):1371–1386

Bhattacharyya A (1984) Metal cutting: theory and practice. Jamini Kanta Sen of Central Book Publishers

Behera BC, Chetan SD, Ghosh S, Rao PV (2017) Spreadability studies of metal working fluids on tool surface and its impact on minimum amount cooling and lubrication turning. J Mater Process Technol 244:1–16. https://doi.org/10.1016/j.jmatprotec.2017.01.016

Maruda RW, Krolczyk GM, Feldshtein E, Pusavec F, Szydlowski M, Legutko S, Sobczak-Kupiec A (2016) A study on droplets sizes, their distribution and heat exchange for minimum quantity cooling lubrication (MQCL). Int J Mach Tools Manuf 100:81–92

Dhar N, Kamruzzaman M (2007) Cutting temperature, tool wear, surface roughness and dimensional deviation in turning AISI-4037 steel under cryogenic condition. Int J Mach Tools Manuf 47(5):754–759

Talib N, Rahim EA (2018) Performance of modified jatropha oil in combination with hexagonal boron nitride particles as a bio-based lubricant for green machining. Tribol Int 118:89–104. https://doi.org/10.1016/j.triboint.2017.09.016

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, M.K., Mia, M., Singh, G. et al. Hybrid cooling-lubrication strategies to improve surface topography and tool wear in sustainable turning of Al 7075-T6 alloy. Int J Adv Manuf Technol 101, 55–69 (2019). https://doi.org/10.1007/s00170-018-2870-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2870-4