Abstract

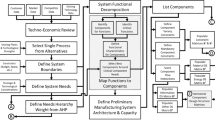

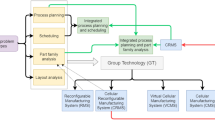

While it is well recognized in the literature that modularity is a very important enabler for reconfigurability in manufacturing systems, there is very limited practical guidance on how the various required functions of a production system should be grouped into modules. In this work, a new heuristic approach is developed and presented, to aid the system developer in the identification and synthesis of potential modules during the early design stage of a reconfigurable manufacturing system. The work involves the identification of key module drivers for such systems, and of key criteria that can be used to facilitate the optimization of the granularity and effectiveness of the system. The results are presented in the form of a semi-algorithmic design tool that can be easily understood and used by the developer. The tool is applied to three very different industrial case studies, and is shown to be applicable to various manufacturing scenarios and sub-sectors. The use of the new tool is compared to the use of a design structure matrix approach to function clustering for module synthesis, and is shown to be easier and more objective in its application.

Similar content being viewed by others

References

Mehrabi MG, Ulsoy AG, Koren Y (2000) Reconfigurable manufacturing systems: key to future manufacturing. J Intell Manuf 11:403–419. https://doi.org/10.1023/A:1008930403506

Koren Y (2006) General RMS characteristics. Comparison with dedicated and flexible systems. Reconfigurable Manuf. In: Syst. Transform. Factories. Springer Berlin Heidelberg, Berlin, Heidelberg, pp 27–45. https://doi.org/10.1007/3-540-29397-3_3

Andersen A-L, Brunoe TD, Nielsen K, Rösiö C (2017) Towards a generic design method for reconfigurable manufacturing systems: analysis and synthesis of current design methods and evaluation of supportive tools. J Manuf Syst 42:179–195. https://doi.org/10.1016/J.JMSY.2016.11.006

Singh A, Gupta S, Asjad M, Gupta P (2017) Reconfigurable manufacturing systems: journey and the road ahead. Int J Syst Assur Eng Manag 8:1849–1857. https://doi.org/10.1007/s13198-017-0610-z

Koren Y, Shpitalni M (2010) Design of reconfigurable manufacturing systems. J Manuf Syst 29:130–141. https://doi.org/10.1016/J.JMSY.2011.01.001

van Voorthuysen E, Olsen J, Langley K, Lipski M, Subramanian K (2017) Design for scalability of industrial processes using modular components. Proc Inst Mech Eng Part B J Eng Manuf 231:1464–1478. https://doi.org/10.1177/0954405415598893

Renzi C, Leali F, Cavazzuti M, Andrisano AO (2014) A review on artificial intelligence applications to the optimal design of dedicated and reconfigurable manufacturing systems. Int J Adv Manuf Technol 72:403–418. https://doi.org/10.1007/s00170-014-5674-1

Bussmann S, Schild K (2001) An agent-based approach to the control of flexible production systems. 8th Int. Conf. Emerg. Technol. Fact. Autom. Proc. (Cat. No.01TH8597), vol. 2, IEEE; n.d., pp 481–488. https://doi.org/10.1109/ETFA.2001.997722

Farid AM, Ribeiro L (2015) An axiomatic design of a multiagent reconfigurable mechatronic system architecture. IEEE Trans Ind Informatics 11:1142–1155. https://doi.org/10.1109/TII.2015.2470528

Khedri Liraviasl K, ElMaraghy H, Hanafy M, Samy SN (2015) A framework for modelling reconfigurable manufacturing systems using hybridized discrete-event and agent-based simulation. IFAC-PapersOnLine 48:1490–1495. https://doi.org/10.1016/J.IFACOL.2015.06.297

Borgo S, Cesta A, Orlandini A, Umbrico A (2016) A planning-based architecture for a reconfigurable manufacturing system. Proc. Twenty-Sixth Int. Conf. Autom. Plan. Sched., AAAI, pp 358–366

Haddou Benderbal H, Dahane M, Benyoucef L (2018) Modularity assessment in reconfigurable manufacturing system (RMS) design: an archived multi-objective simulated annealing-based approach. Int J Adv Manuf Technol 94:729–749. https://doi.org/10.1007/s00170-017-0803-2

Shaik AM, Rao VVSK, Rao CS (2015) Development of modular manufacturing systems—a review. Int J Adv Manuf Technol 76:789–802. https://doi.org/10.1007/s00170-014-6289-2

Rogers GG, Bottaci L (1997) Modular production systems: a new manufacturing paradigm. J Intell Manuf 8:147–156. https://doi.org/10.1023/A:1018560922013

Huang C-C, Kusiak A (1998) Modularity in design of products and systems. IEEE Trans Syst Man, Cybern - Part A Syst Humans 28:66–77. https://doi.org/10.1109/3468.650323

Malhotra V, Raj T, Arora A (2009) Reconfigurable manufacturing system: an overview. Int J Mach Intell 1:38–46. https://doi.org/10.9735/0975-2927.1.2.38-46

Harrison R, Lee SM, Ong MH, West AA (2006) Distributed engineering of modular reconfigurable automation systems. Proc. 12th IFAC Int. Symp. Inf. Control Probl. Manuf. St Etienne, France, pp 523–528

Kamrani AK, Gonzalez R (2003) A genetic algorithm-based solution methodology for modular design. J Intell Manuf 14:599–616. https://doi.org/10.1023/A:1027362822727

Koren Y, Heisel U, Jovane F, Moriwaki T, Pritschow G, Ulsoy G, van Brussel H (1999) Reconfigurable manufacturing systems. CIRP Ann 48:527–540. https://doi.org/10.1016/S0007-8506(07)63232-6

Rösiö C, Säfsten K (2013) Reconfigurable production system design—theoretical and practical challenges. J Manuf Technol Manag 24:998–1018. https://doi.org/10.1108/JMTM-02-2012-0021

Azzopardi S, Saliba MA, Zammit D, Pace C (2009) An intersectoral reconfigurable manufacturing automation testbed: preliminary design considerations. Proc ASME/IFToMM Int Conf Reconfigurable Mech Robot pp 696–704

Fredriksson P (2006) Mechanisms and rationales for the coordination of a modular assembly system: the case of Volvo cars. Int J Oper Prod Manag 26:350–370. https://doi.org/10.1108/01443570610650530

Bi ZM, Zhang WJ (2001) Modularity technology in manufacturing: taxonomy and issues. Int J Adv Manuf Technol 18:381–390. https://doi.org/10.1007/s001700170062

Kusiak A (2002) Integrated product and process design: a modularity perspective. J Eng Des 13:223–231. https://doi.org/10.1080/09544820110108926

Ericsson A, Erixon G (1999) Controlling design variants: modular product platforms. Society of Manufacturing Engineers, Dearborn, MI

Deif AM, ElMaraghy WH (2006) A systematic design approach for reconfigurable manufacturing systems. In: ElMaraghy HA, ElMaraghy WH (eds) Adv. Des. Springer London, London, pp 219–228. https://doi.org/10.1007/1-84628-210-1_18

Moon YM (2006) Reconfigurable machine tool design. In: Reconfigurable machine tool design. Reconfigurable Manuf. Syst. Transform. Factories. Springer, Berlin, Heidelberg, pp 111–139. https://doi.org/10.1007/3-540-29397-3_7

Pérez RR, Aca SJ, Valverde TA, Ahuett GH, Molina GA, Riba RC (2004) A modularity framework for concurrent design of reconfigurable machine tools. Springer, Berlin, Heidelberg, pp 87–95. https://doi.org/10.1007/978-3-540-30103-5_10

Browning TR (2016) Design structure matrix extensions and innovations: a survey and new opportunities. IEEE Trans Eng Manag 63:27–52. https://doi.org/10.1109/TEM.2015.2491283

ElMaraghy H, AlGeddawy T (2015) A methodology for modular and changeable design architecture and application in automotive framing systems. J Mech Des 137:121403. https://doi.org/10.1115/1.4031549

Lameche K, Najid NM, Castagna P, Kouiss K (2017) Modularity in the design of reconfigurable manufacturing systems. IFAC-PapersOnLine 50:3511–3516. https://doi.org/10.1016/J.IFACOL.2017.08.939

Thebeau RE (2001) Knowledge management of system interfaces and interactions for product development process. Dissertation, Massachusetts Institute of Technology

Adams KM (2015) Design methodologies. Springer, Cham, pp 15–43. https://doi.org/10.1007/978-3-319-18344-2_2

Spiewak SA, Duggirala R, Barnett K (2000) Predictive monitoring and control of the cold extrusion process. CIRP Ann 49:383–386. https://doi.org/10.1016/S0007-8506(07)62970-9

Downtime Costs Auto Industry $22k/Minute-Survey n.d. https://news.thomasnet.com/companystory/downtime-costs-auto-industry-22k-minute-survey-481017. Accessed 4 Feb 2019

Nofen D, Klussmann J, Loellmann F (2003) Transformability by modular facility structures. Proc. 2nd CIRP Int. Conf. Reconfigurable Manuf., Ann Arbor, MI

Heisel U, Meitzner M (2004) Progress in reconfigurable manufacturing systems. J Manuf Sci Prod 6:1–8

Rauch E, Matt DT, Dallasega P (2016) Application of axiomatic design in manufacturing system design: a literature review. Procedia CIRP 53:1–7. https://doi.org/10.1016/J.PROCIR.2016.04.207

Thebeau RE (2001) Matlab DSM Clustering Code. http://www.dsmweb.org/en/dsm-tools/research-tools/matlab.html. Accessed 4 Feb 2019

Funding

This work was funded by the Maltese National Research and Innovation Programme through the Malta Council for Science and Technology (Contract Number R&I-2006-045).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saliba, M.A., Azzopardi, S., Pace, C. et al. A heuristic approach to module synthesis in the design of reconfigurable manufacturing systems. Int J Adv Manuf Technol 102, 4337–4359 (2019). https://doi.org/10.1007/s00170-019-03444-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03444-4