Abstract

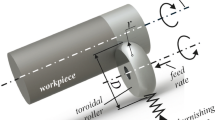

The paper presents a deep experimental study on surface modifications induced by roller burnishing process of Ti6Al4V titanium alloy. The experimental campaign has been performed based on a design of experiments at varying lubrication/cooling strategies, roller geometry, coating, and burnishing speed. The overall surface integrity has been analyzed in terms of surface roughness, micro hardness, topography, microstructural changes, and tribological performance. The results allowed to better define the relationships within burnishing process parameters and the surface quality of the final component. In particular, the obtained evidences show that cryogenic cooling conditions and coating tools significantly improve the hardness of the final component while the MQL lubrication leads to superior surface roughness. Overall, the process always improves the wear resistance of the components with optimal results when cryogenic cooling and coated tools are employed. Thus, the outcomes of the extensive experimental campaign allow to define a combination of process parameters leading to improved Ti6Al4V surface quality.

Similar content being viewed by others

References

Jawahir IS, Attia H, Biermann D, Duflou J, Klocke F, Meyer D, Newman ST, Pusavec F, Putz M, Rech J, Schulze V, Umbrello D (2016) Cryogenic manufacturing processes. CIRP Annals 65(2):713–736

Papadia G, Del Prete A, Manisi B, Anglani A (2010) Blank shape optimization in sheet metal hydromechanical deep drawing (HDD). Int J Mater Form 3(1):291–294

Del Prete A, Primo T, Franchi R (2013) Super-nickel orthogonal turning operations optimization. Procedia CIRP 8:164–169

Calabrese M, Primo T, Del Prete A (2017) Optimization of machining fixture for aeronautical thin-walled components. Procedia CIRP 60:32–37

Rotella G, Alfano M, Candamano S (2015) Surface modification of Ti6Al4V alloy by pulsed Yb-laser irradiation for enhanced adhesive bonding. CIRP Annals 64(1):527–530

Wu Z, Wang W, Li W, Yan M, Li Y (2019) Microstructure and mechanical properties of Ti-6Al-4V prepared by nickel preplating and electron beam surface remelting. J Mater Process Technol 271:420–428

Sachin B, Narendranath S, Chakradhar D (2019) Effect of working parameters on the surface integrity in cryogenic diamond burnishing of 17-4 PH stainless steel with a novel diamond burnishing tool. J Manuf Proc 38:564–571

Schulze V, Bleicher F, Groche P, Guo YB, Pyun YS (2016) Surface modification by machine hammer peening and burnishing. CIRP Annals 65(2):809–832

Tang J, Luo HY, Zhang YB (2017) Enhancing the surface integrity and corrosion resistance of Ti-6Al-4V titanium alloy through cryogenic burnishing. Int J Adv Manuf Technol 88:2785–2793. https://doi.org/10.1007/s00170-016-9000-y

Hiegemann L, Weddeling C, Ben Halifa N, Tekkaya AE (2015) Prediction of roughness after ball burnishing of thermally coated surfaces. K Mater Process Technol 217:193–201

Maximov JT, Duncheva GV, Anchev AP, Ichkova MD (2019) Slide burnishing – review and prospects. The International Journal of Advanced Manufacturing Technology 104:785–801. https://doi.org/10.1007/s00170-019-03881-1

Courbon C, Sova A, Valiorguea F, Pascal H, Sijobert J, Kermouche G, Bertrand P, Rech J (2019) Near surface transformations of stainless steel cold spray and laser cladding deposits after turning and ball-burnishing. Surf Coatings Technol 371:235–244

Khalilpourazary S, Salehi J (2019) How alumina nanoparticles impact surface characteristics of Al7175 in roller burnishing process. J Manuf Process 39:1–11

Abrao AM, Denkena B, Breidenstein B, Mörke T (2014) Surface and subsurface alterations induced by deep rolling of hardened AISI 1060 Steel. Prod Eng Res Dev 8:551–558

El-Taweel TA, El-Axir MH (2009) Analysis and optimization of the ball burnishing process through the Taguchi technique. Int J Adv Manuf Techn 41(3-4):301–310

Luo H, Liu J, Wang L, Zhong Q (2006) Investigation of the burnishing force during the burnishing process with a cylindrical surfaced tool. J Eng Manuf Part B 220:893–904

Caudill J, Schoop J, Jawahir IS (2018) Correlation of surface integrity with processing parameters and advanced interface cooling/lubrication in burnishing of Ti-6Al-4V alloy. Adv Mater Proc Techn 5-1:53–66

Imbriglio SI, Hassani-Gangaraj M, Veysset D, Aghasibeig M, Gauvin R, Nelson KA, Schuh CA, Chromik RR (2019) Adhesion strength of titanium particles to alumina substrates: a combined cold spray and LIPIT study. Surf Coath Tech 361:403–412

Assadi H, Gartner F, Stoltenhoff T, Kreye H (2003) Bonding mechanism in cold gas spraying. Acta Materialia 51:4379–4394

Zhou J, Sun Y, Huang S, Sheng J, Li J, Agyenim-Boateng E (2019) Effect of laser peening on friction and wear behavior of medical Ti6Al4V alloy. Opt Laser Technol 109:263–269

Devaraya Revankar GD, Shetty R, Rao SS, Gaitonde VN (2017) Wear resistance enhancement of titanium alloy (Ti–6Al–4V) by ball burnishing process. J Mater Res Techn 6(1):13–32

Rotella G, Filice L (2019) Surface modifications induced by roller burnishing of Ti6Al4V under different cooling/lubrication conditions. proceedings of the 14th conference of Italian Association of Manufacturing Technology, September 9-11th 2019, Padova (ITALY), pp 1-10

Wang YM, Ma E, Valiev RZ, Zhu YT (2004) Tough nanostructured metals at cryogenic temperatures. Adv Mater 16(4):328–331

Wei Q, Cheng S, Ramesh KT, Ma E (2004) Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: fcc versus bcc metals. Mater Sci Eng 381(1):71–79

Marani SM, Shahgholi G, Moinfar A (2019) Effect of nano coating materials on reduction of soil adhesion and external friction. Soil Tillage Res 193:42–49

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rotella, G., Rinaldi, S. & Filice, L. Roller burnishing of Ti6Al4V under different cooling/lubrication conditions and tool design: effects on surface integrity. Int J Adv Manuf Technol 106, 431–440 (2020). https://doi.org/10.1007/s00170-019-04631-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04631-z