Abstract

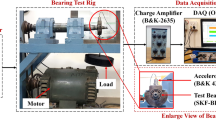

In this paper, we propose a novel method for the classification of bearing faults using a convolutional neural network (CNN) and vibration spectrum imaging (VSI). The normalized amplitudes of the spectral content extracted from segmented temporal vibratory signals using a time-moving segmentation window are transformed into spectral images for training and testing of the CNN classifier. To show the efficiency of the proposed method, vibratory data for healthy and faulted bearings operating at different speeds are collected from an experimental test bench. The classification accuracy, variable load and speed testing, generalization, and robustness by adding noise to the collected data at different levels (SNR) are then evaluated. The obtained experimental classification results show excellent performance in terms of both accuracy and robustness.

Similar content being viewed by others

References

Immovilli F, Cocconcelli M, Bellini A, Rubini R (2009) Detection of generalized-roughness bearing fault by spectral-kurtosis energy of vibration or current signals. IEEE Trans Ind Electron 56(11):4710–4717

Lin J, Zuo MJ (2003) Gearbox fault diagnosis using adaptive wavelet filter. Mech Syst Signal Process 17(6):1259–1269

Henriquez P, Alonso JB, Ferrer MA, Travieso CM (2014) Review of automatic fault diagnosis systems using audio and vibration signals. IEEE Trans Syst Man Cybern Syst 44(5):642–652

Wang J, Peng Y, Qiao W (2016) Current-aided order tracking of vibration signals for bearing fault diagnosis of direct-drive wind turbines. IEEE Trans. Ind. Electron. 63(10):6336–6346

Zhang B, Sconyers C, Byington C, Patrick R, Orchard ME, Vachtsevanos G (2011) A probabilistic fault detection approach: application to bearing fault detection. IEEE Trans Ind Electron 58(5):2011–2018

Kang M, Islam MR, Kim J, Kim J-M, Pecht M (2016) A hybrid feature selection scheme for reducing diagnostic performance deterioration caused by outliers in data-driven diagnostics. IEEE Trans Ind Electron 63(5):3299–3310

He D, Li R, Zhu J (2012) Plastic bearing fault diagnosis based on a two-step data mining approach. IEEE Trans Ind Electron :1–1

Zheng J, Pan H, Cheng J (2017) Rolling bearing fault detection and diagnosis based on composite multiscale fuzzy entropy and ensemble support vector machines. Mech Syst Signal Process 85:746–759

Prieto MD, Cirrincione G, Espinosa AG, Ortega JA, Henao H (2013) Bearing fault detection by a novel condition-monitoring scheme based on statistical-time features and neural networks. IEEE Trans Ind Electron 60(8):3398–3407

Lei Y, He Z, Zi Y (2008) A new approach to intelligent fault diagnosis of rotating machinery. Expert Syst Appl 35(4):1593–1600

Attoui I, Fergani N, Boutasseta N, Oudjani B, Deliou A (2017) A new time–frequency method for identification and classification of ball bearing faults. J Sound Vib 397:241–265

He W, Yin C, and Chen X. (2013) “Nonlinear methods for rolling bearing fault diagnosis” 2013 Ninth International Conference on Natural Computation (ICNC), pp. 168–172. https://doi.org/10.1109/ICNC.2013.6817964

Shao H, Jiang H, Zhang H, Liang T (2018) Electric locomotive bearing fault diagnosis using a novel convolutional deep belief network. IEEE Trans Ind Electron 65(3):2727–2736

Jia F, Lei Y, Lin J, Zhou X, Lu N (2016) Deep neural networks: a promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech Syst Signal Process 72–73:303–315

Hoang D-T and Kang H-J, (2017) “Convolutional neural network based bearing fault diagnosis BT - Intelligent Computing Theories and Application,” 2017, pp. 105–111. https://doi.org/10.1007/978-3-319-63312-1_9

Xu G, Liu M, Jiang Z, Söffker D, Shen W (2019) Bearing fault diagnosis method based on deep convolutional neural network and random forest ensemble learning. Sensors 19(5):1088

Amar M, Gondal I, Wilson C (2015) Vibration spectrum imaging: a novel bearing fault classification approach. IEEE Trans Ind Electron 62(1):494–502

Liu R, Yang B, Zio E, Chen X (2018) Artificial intelligence for fault diagnosis of rotating machinery: a review. Mech Syst Signal Process 108:33–47

Nguyen D, Kang M, Kim C-H, Kim J-M (2013) Highly reliable state monitoring system for induction motors using dominant features in a two-dimension vibration signal. New Rev Hypermedia Multimed 19(3–4):248–258

Matsugu M, Mori K, Mitari Y, Kaneda Y (2003) Subject independent facial expression recognition with robust face detection using a convolutional neural network. Neural Networks 16(5–6):555–559

Xie Y, Zhang T (2017) Fault diagnosis for rotating machinery based on convolutional neural network and empirical mode decomposition. Shock Vib 2017:1–12

LeCun Y, Bengio Y, Hinton G (2015) Deep learning. Nature 521(7553):436–444

Lessmann S, Baesens B, Mues C, Pietsch S (2008) Benchmarking classification models for software defect prediction: a proposed framework and novel findings. IEEE Trans Softw Eng 34(4):485–496

Loparo KA (2012) “Case western reserve university bearing data center [online], Available:URL: http://www.eecs.cwru.edu/laboratory/bearing/download.htm, 2019

Xia M, Li T, Xu L, Liu L, De Silva CW (2018) Fault diagnosis for rotating machinery using multiple sensors and convolutional neural networks. IEEE/ASME Trans Mechatronics 23(1):101–110

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Youcef Khodja, A., Guersi, N., Saadi, M.N. et al. Rolling element bearing fault diagnosis for rotating machinery using vibration spectrum imaging and convolutional neural networks. Int J Adv Manuf Technol 106, 1737–1751 (2020). https://doi.org/10.1007/s00170-019-04726-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04726-7